Alumina silica refractory bricks are acid-and alkali-resistant refractory materials primarily composed of silica and alumina. They offer high refractoriness, slag resistance, thermal shock resistance, and excellent mechanical properties. These bricks are widely used in applications such as kiln linings and pipework.

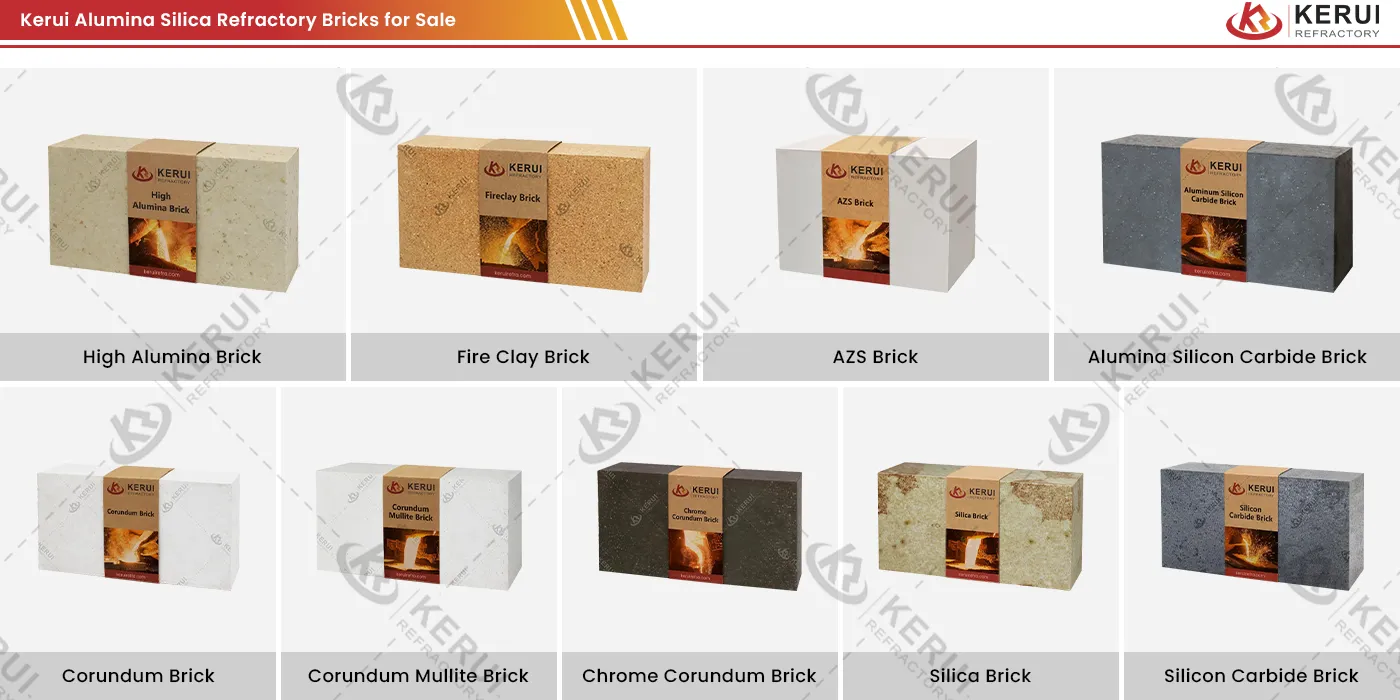

Types of Kerui Alumina Silica Refractory Bricks

Alumina silica refractory bricks are a type of refractory brick made by firing a mixture of Al2O3, SiO2, and additives. According to the composition content of alumina and silicon oxide, Kerui Refractory offers the following types of alumina silica refractory bricks:

Different Sizes of Alumina Silicate Brick

Common shapes: Standard straight brick, axe-shaped brick, knife-shaped brick, wedge-shaped brick, two-piece/four-piece brick, half-strip brick, anchor brick, runner brick/steel brick, pre-hole/rod-hole brick, arch foot brick, checker brick, composite brick, general-purpose curved brick, curved brick, etc.

Commonly used in various industries: Blast furnace bricks, hot blast furnace bricks, heating furnace bricks, boiler bricks, electric furnace bricks, rotary kiln bricks, glass melting furnace bricks, ladle bricks, refining furnace bricks, reactor furnace bricks, ceramic kiln bricks, etc.