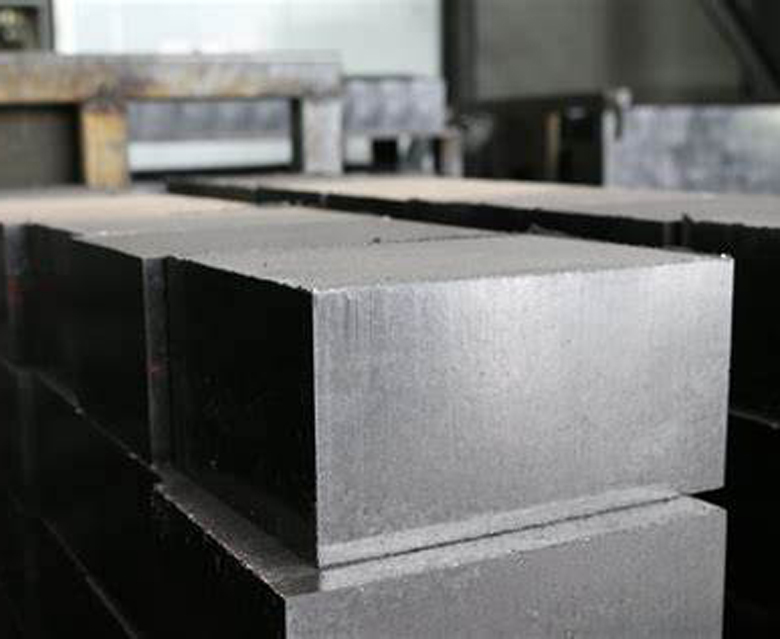

Alumina magnesia carbon brick is a type of composite refractory material. They exhibit stable performance in industries such as metallurgy and petrochemicals. Kerui offers a variety of brick specifications and can customize bricks based on customer requirements. Kerui is dedicated to providing solutions for high-temperature industries, delivering greater benefits to its customers.

- Al2O3: ≥30-45%;

- Bulk Density: 1.9-2.22g/cm³;

- Refractoriness Under Load: 1250-1420ºC;

- Cold Crushing Strength: 30-45MPa;

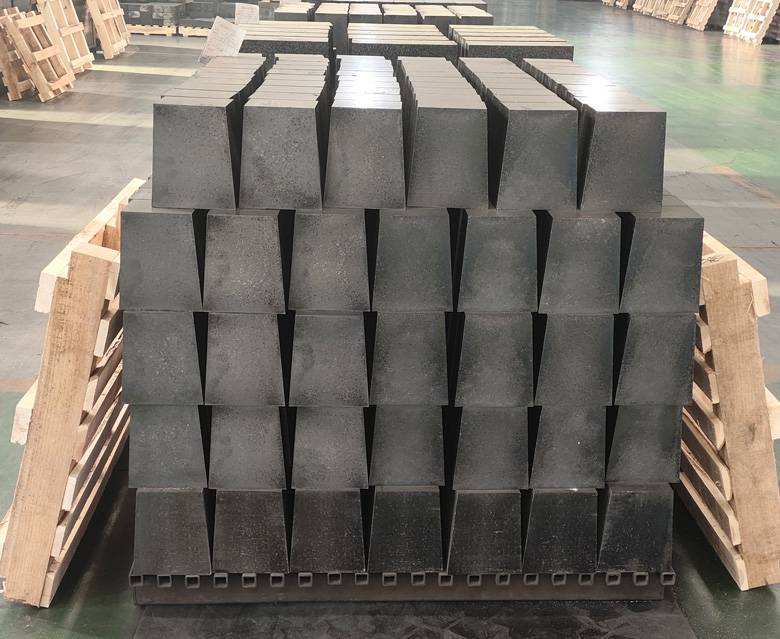

- Size: 230*114*65mm (standard)/And other sizes;

Parameters of Alumina Magnesia Carbon Bricks

Kerui will provide different alumina magnesia carbon bricks based on your furnace type, like ladle, molten steel.

| Item | KR AMC-5 | KR AMC-10 |

|---|---|---|

| MgO in DBM (%) | 10 | 10 |

| Al2O3 (%) | 60 | 60 |

| Fixed C (%) | 5 | 8 |

| A.P. (%) | 7 | 8 |

| B.D (gm/cm3) | 2.95 | 2.92 |

| C.C.S (kg/cm2) | 400 | 400 |

| Primary Raw Materials | Calcined Bauxite, Fused Magnesia and Graphite | |

| Application | Metal Zone and Bottom of LRF, VD , BOF and VOD | |

High-Quality Control for Kerui Magnesia Alumina Carbon Bricks

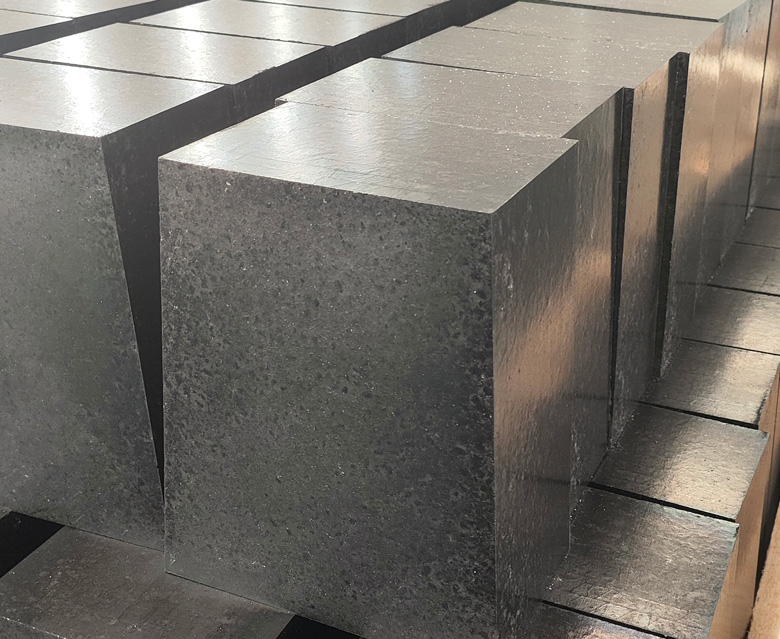

- Kerui’s magnesia alumina carbon bricks are made from premium raw materials, including bauxite, corundum, fused magnesia, and graphite.

- The raw materials are precisely proportioned and uniformly mixed.

- The manufacturing process features automated operations for pressing, demolding, mold locking, and injection. With accurate volumetric feeding, bidirectional pressing, and hydrostatic pressure, the refractory bricks achieve high density, stable quality, and precise dimensions.

- The bricks are fired at high temperatures in a 168-meter-long tunnel kiln.

- The final products undergo grinding, measurement, and inspection to ensure quality.

Features of Alumina Magnesia Carbon Brick

- Resistance to slag erosion;

- Resistance to molten steel corrosion;

- Excellent spalling resistance;

- Good thermal stability;

- Low thermal conductivity;

- Strong oxidation resistance;

- Superior insulation performance, better than magnesia-carbon bricks;

- Moderate residual linear expansion;

- Better spalling resistance compared to magnesia-carbon bricks in ladles;

- Enhanced matrix;

- Excellent structural integrity;

- High resistance to thermal shock.

Note: To enhance the oxidation resistance of alumina magnesia carbon bricks, appropriate additives such as silicon powder, aluminum powder, silicon carbide powder, or ferrosilicon powder can be incorporated.

Shipping and Delivery of Kerui Alumina Magnesia Carbon Bricks

Kerui Refractory has a strict production schedule and delivery system. These rigorous processes enable us to efficiently and promptly handle large orders. Normally, the delivery circle is about 15-30 working day.

Due to Kerui’s strong relationships with major shipping companies, we are able to offer customers the best shipping routes and the fastest delivery times.

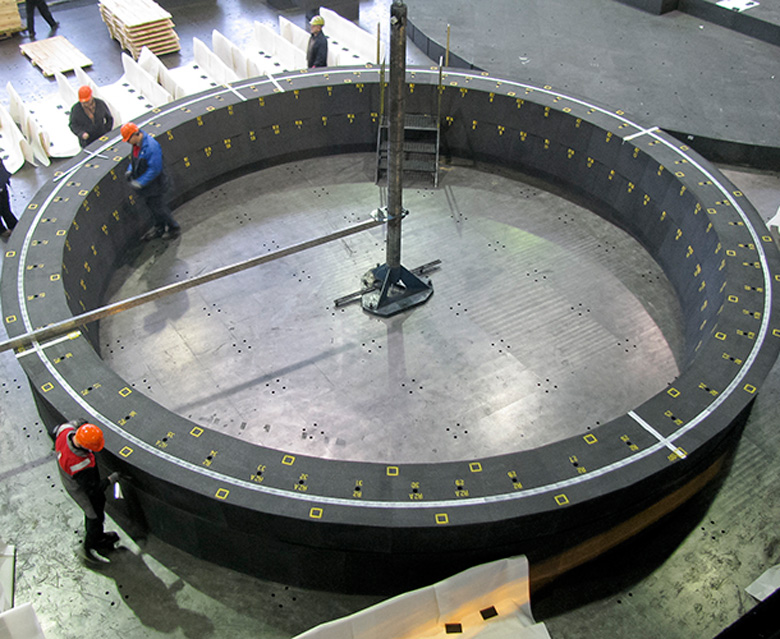

Application of AMC Bricks

Application of alumina magnesia carbon bricks is widely in metallurgical equipment such as ladle furnaces and refining ladles. They are mainly applied to the side walls, slag lines, and bottoms of ladles. During use, they can adsorb non-metallic impurities in the molten steel, achieving the goal of steel purification. They are a high-quality alternative to corundum and high-alumina refractory bricks.

- Steel Industry: Converter linings, electric arc furnace linings, ladles, etc.

- Non-ferrous Metal Metallurgy: Furnace linings for the smelting of non-ferrous metals like copper and aluminum.

- Petrochemical Industry: Petroleum cracking furnaces, catalytic cracking units, etc.

- Glass Industry: Glass melting furnaces, etc.

Kerui Services

Pre-Sales Service:

- One-on-one consultation with a professional International Business Manager.

- Recommendations for suitable products based on the customer’s specific operating conditions and requirements.

- Customization services available upon request.

In-Sales Service:

- Products undergo strict quality inspections to meet standards.

- Drawings can be provided according to customer requirements.

- Professional certificates and document support are available.

After-Sales Service:

- Provision of technical guidance for installation.

- On-site support and supervision.

If you wanna see more videos, view Kerui YouTube.