Acid proof brick lining is a lining brick designed to resist strong corrosive chemicals and strong acids. It is often used in industrial environments that require chemical corrosion protection. Keri can recommend suitable brick lining and matching materials based on the customer’s usage scenarios and operating conditions. Keri bricks have excellent performance and long-lasting protection. We offer a variety of sizes and custom brick shapes.

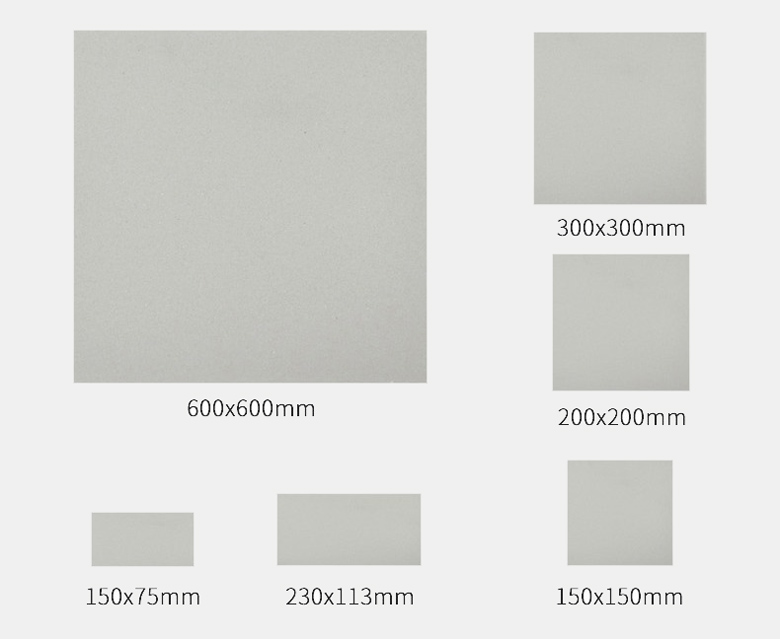

Sizes of Acid Proof Lining

| Thickness 15mm | Thickness 20mm | Thickness 30mm | Thickness 40mm | Thickness 50mm | Thickness 65mm |

| 150*75*15; 150*150*15; 200*200*15; 230*113*15; 300*300*15; 300*600*15; 600*600*15; |

150*75*20; 150*150*20; 200*200*20; 230*113*20; 300*300*20; 300*600*20; 600*600*20; |

150*150*30; 200*200*30; 230*113*30; 300*300*30; |

230×113×40; | 230×113×50; | 230×113×65; |

Features of Acid Proof Brick Lining

Main raw materials of Kerui acid proof brick lining procedure are high-quality quartz, feldspar and clay. It forms a large amount of mullite under high temperature roasting. And it contains more than 70% silica. Therefore, this brick has the following good properties.

- High acid resistance, resistant to corrosion by strong acids such as sulfuric acid, hydrochloric acid, and nitric acid;

- Good corrosion resistance except for hydrofluoric acid and hot phosphoric acid;

- Not easy to oxidize;

- High density;

- High wear resistance;

- High compressive strength;

- Low water absorption and impermeability;

- Not easy to be contaminated by the media.

- Suitable for a variety of installation processes, it can be hardened in a humid environment or underwater.

- Strong adhesion with a variety of materials;

- Cost saving;

- Easy to clean.

Applications of Kerui Acid Proof Brick Lining

As the leading acid proof bricks manufacturers, Kerui provides high-performance acid proof lining and customized solutions for corrosion protection needs in different industries. Our products use high-quality raw materials and advanced processes to ensure excellent durability under strong acid, high temperature and complex working conditions, helping customers extend equipment life and reduce maintenance costs.

Acid Proof Brick Lining for Chemical Industry

Kerui offers solutions for the following industries:

- Basic chemical plants: Sulfuric acid plants, hydrochloric acid plants, nitric acid plants, phosphoric acid and phosphorus chemical enterprises, hydrofluoric acid production units.

- Petrochemical plants: Refinery pickling units, ethylene cracking unit quench towers, alkylation reaction zones in aromatics production.

- Fertilizer production enterprises: Urea synthesis towers, compound fertilizer granulation towers, ammonia desulfurization units.

- Pesticide and dye chemical plants.

| Application | Acid Tanks/Reactor Linings | Pipeline/Trench Linings |

| Recommended Sizes (mm) | 230×113×65, 300×300×30 |

150×75×15, 200×200×20 |

| Key Functions | Resists strong acids (sulfuric/hydrochloric), minimizes joint leakage |

Adapts to elbow structures, prevents acid wastewater penetration |

| Special Requirements | Thick bricks require acid-resistant mortar | Small bricks need expansion joints |

For Metallurgy/Electroplating Industry

- Electroplating plant: Used for lining electroplating tanks and pickling tanks to prevent corrosion from sulfuric acid, hydrochloric acid, cyanide, etc.

- Steel pickling workshop: Acid proof bricks are used to pave pickling tanks and waste gas treatment towers (resistant to hydrochloric acid and sulfuric acid mist corrosion).

- Steel rolling mill: Used for cold rolling acid regeneration system, resistant to hydrofluoric acid corrosion.

- Nonferrous metal smelting plant: Electrolytic cells and flue gas purification towers in copper and zinc smelting (resistant to sulfuric acid and nitric acid corrosion).

| Application | Pickling Tanks/Electrolytic Cells | Smelter Flue Gas Treatment |

| Recommended Sizes (mm) | 230×113×40/50, 300×300×20 |

150×150×30, 400×400×20 |

| Key Functions | Withstands HCl/cyanide corrosion, easy-to-clean surface |

Resists acidic slag and condensate |

| Special Requirements | Requires current-resistant materials for electrolytic cells | Must withstand thermal shock (200-600°C) |

For Environmental/Energy

- Sewage treatment plant: Acidic wastewater treatment tank, sludge concentration tank (anti-mixed acid and alkali).

- Thermal power plant: Desulfurization tower (FGD) lining, anti-sulfurization and anti-chloride ion corrosion (need to withstand temperatures above 300°C).

- Waste incineration plant: Flue gas purification device (HCl, SO₂ corrosion protection).

| Application | Wastewater Treatment Tanks | Power Plant Desulfurization Towers |

| Recommended Sizes (mm) | 230×113×30, 600×600×15 |

300×300×30, 230×113×65 |

| Key Functions | Resists mixed acid/alkali corrosion, enables fast installation |

Resists sulfurous wet gas erosion and chemical corrosion |

| Special Requirements | Tank floors need FRP reinforcement | Regular joint inspections required |

For Food/Pharmaceutical

- Dairy factory: Fermentation tank, CIP cleaning system (glazed acid resistant tiles are required).

- Pharmaceutical factory: Reactor, solvent recovery equipment (resistant to organic acids such as citric acid and acetic acid).

- Juice/beverage factory: Storage tank, filling line anti-corrosion (resistance to fruit acid corrosion, easy to clean glazed tiles).

| Application | Fermentation Tanks/Equipment Linings |

| Recommended Sizes (mm) | 150×150×15 (glazed), 100×100×10 |

| Key Functions | Meets FDA hygiene standards, resists organic acids |

| Special Requirements | Non-porous surface for sterilization |

For Other Industry

- Chemical fiber plant: Acid bath in viscose fiber production (resistance to sulfuric acid + hydrogen sulfide combined corrosion).

- Paper mill: Bleaching workshop, waste liquid treatment pool (resistance to chlorine-alkali corrosion).

- Laboratory: Fume hood, waste liquid collection pool.

| Application | Lab Countertops/Floors | Acidic Soil Foundations |

| Recommended Sizes (mm) | 80×80×10, 200×200×15 |

230×113×60 |

| Key Functions | Wear-resistant, easy to clean | Prevents acidic groundwater from corroding concrete |

| Special Requirements | Glazed surfaces prevent reagent penetration | Requires asphalt isolation layer |

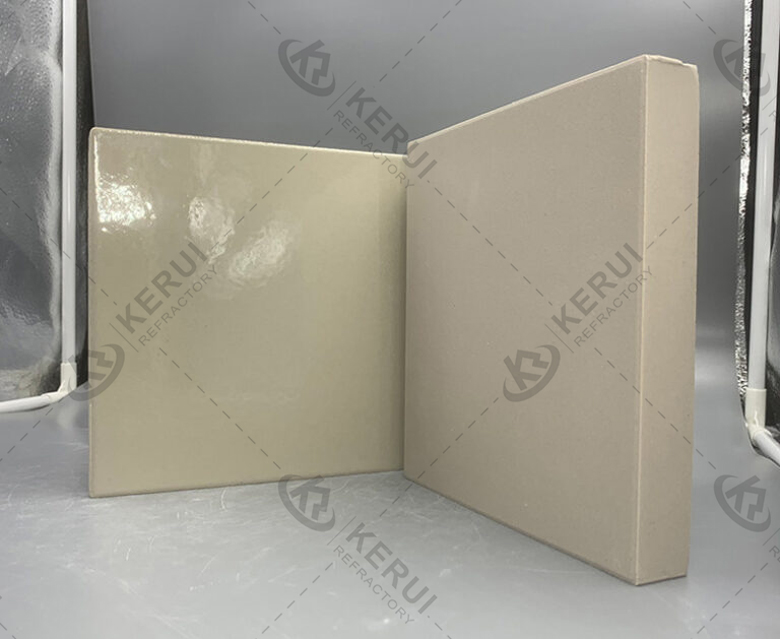

Unglazed Bricks VS. Glazed Tiles

| Types | Descriptions | Advantages |

| Plain Unglazed Bricks Type | There is no glaze on the surface of this type of acid proof tile linings. | Non-slip; high hardness; Wear resistance; |

| Glazed Tiles Type | The surface of this type of tiles is glazed. The back of the product is added with a dovetail groove. | Easy to clean; Low density and high hardness; Be convenient for firm bonding with acid resistant mud during construction and is not easy to fall off. Easy to clean; Extend the service life of the project. |

Parameters of Acid Proof Brick Lining

Kerui offers the following standard types of acid resistant bricks lining. Please refer to the specifications:

| Grade | Z-1 |

|---|---|

| Al₂O₃, % | 20–30 |

| SiO₂, % | 60–70 |

| Fe₂O₃, % | ≤2.0 |

| Na₂O + K₂O, % | ≤5.0 |

| CaO + MgO, % | ≤2.0 |

| Water Absorption, % | ≤0.2 |

| Bending Strength, MPa | ≥58.8 |

| Bulk Density, g/cm³ | 2.3-2.5 |

| Acid Resistance, % | ≥99.8 |

Good Reviews on Kerui Proof Brick Lining

“Kerui, as the acid proof bricks suppliers, sent a sample first. After our confirmation, they sent a large number of acid proof bricks. The quality is very good. The acid poof bricks have standard in size, and have a very positive color. The service attitude is good and I am very happy.”

“The acid proof bricks have very good bonding effect, high acid resistance, smooth surface, and are very easy to use.”

“This brick is of good quality, with a test report. And this brick is in line with national standards. The water absorption rate is less than 0.5%, the color is consistent without color difference, and the bricks from well-known manufacturers are different.”

“We paved 1500 square meters of anti-corrosion floor with anti-corrosion and acid proof bricks lining. Kerui was awesome. The test data passed and the quality was very good. And the acid proof bricks price is very competitive. Kerui was very professional and answered all questions. The delivery speed was great.”

Contact Kerui Refractory

Kerui Refractory has more than 20 years of manufacturing and exporting refractory bricks. We have international certificates, patents of refractory bricks, and other certificates. We have strong production capacity and strict quality control system to guarantee the quality. Moreover, our professional manager and technical professionals will guide you to choose the suitable bricks and high-temperature construction. View some video on Kerui YouTube.