Acid Alkali Resistant Tile

Acid alkali resistant tile is engineered to withstand aggressive chemical environments. This makes them indispensable in industries where corrosion resistance is critical. Kerui offers different shapes and specifications to more than 50+ customers. They have good feedback for us.

- Free Sample:

- Available

- Document:

- Cerficates supporting

- Performance Test:

- Support

- Shipment:

- 7-35 working days

Specifications of Acid Alkali Resistant Tiles

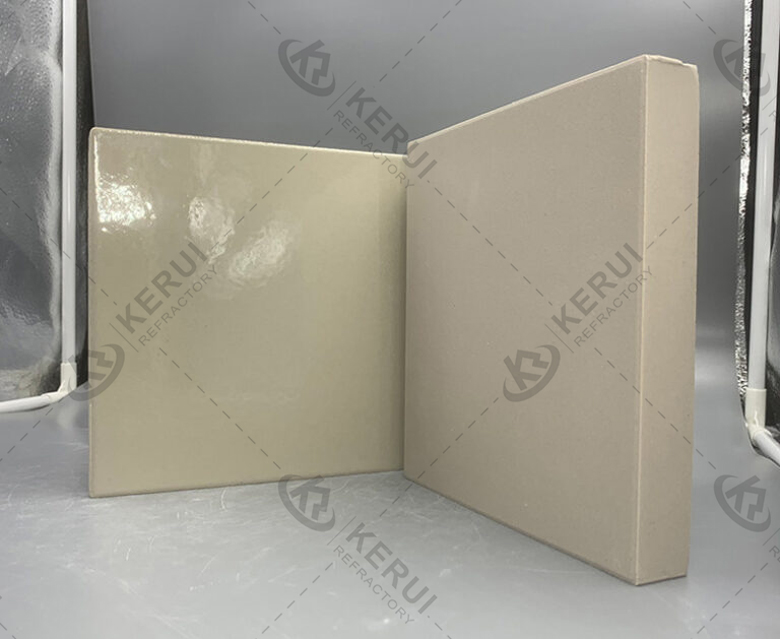

Acid alkali proof tiles are ceramic or porcelain-based materials treated with specialized formulations (like resin impregnation treatment, silica coatings, vitrification) to resist chemical degradation. See the specifications.

| Grade | Z-1 |

|---|---|

| Al₂O₃, % | 20–30 |

| SiO₂, % | 60–70 |

| Fe₂O₃, % | ≤2.0 |

| Na₂O + K₂O, % | ≤5.0 |

| CaO + MgO, % | ≤2.0 |

| Water Absorption, % | ≤0.2 |

| Bending Strength, MPa | ≥58.8 |

| Bulk Density, g/cm³ | 2.3-2.5 |

| Acid Resistance, % | ≥99.8 |

Features of Acid Alkali Resistant Tiles

- Bidirectional corrosion resistance: Simultaneously resists weak acids (pH ≥ 3) and weak bases (pH ≤ 11);

- Zero permeability surface: Borosilicate glaze has low water absorption;

- Extremely easy to clean: The glaze is smooth (roughness Ra ≤ 0.4μm), and stains can be wiped away;

- Physically strong: withstands light mechanical friction.

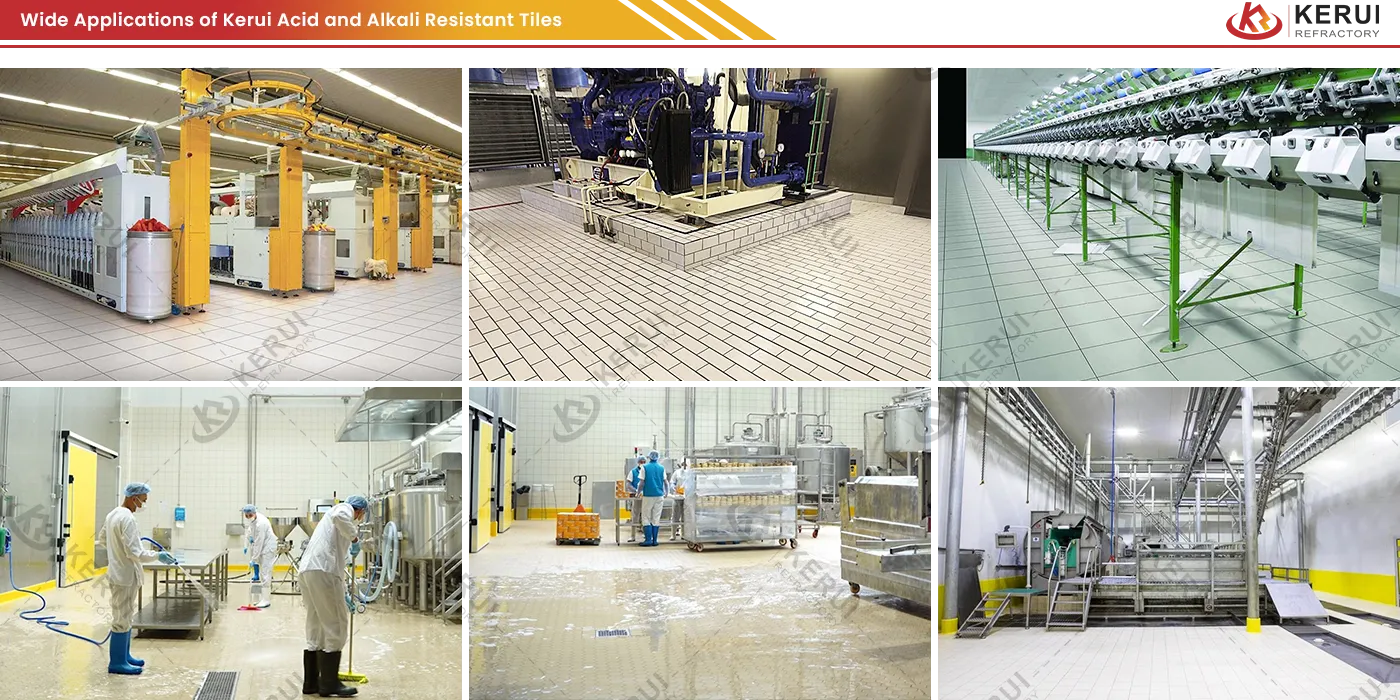

Applications of Acid and Alkali Resistant Tiles

Laboratory countertops: Surface lining for drug testing tables, and this product block leaks from reagents like 5% sulfuric acid and 75% alcohol.

Pipelines and drainage ditches: Line acid transfer pipes and workshop drainage channels, and tolerate splashes of hydrochloric or nitric acid below 20% concentration.

Pickling workshop floors: Surrounding steel plant acid baths, and resist 10% sulfuric acid splashes and heavy metal ion buildup.

Filter tanks in water treatment plants: These tiles shield concrete bases, and prevent erosion from sodium hypochlorite bleach agent.

Material Selection and Formats

Glazed tiles: Offer smoother surfaces for easy cleaning.

Unglazed tiles: Ideal for high-abrasion areas due to their homogeneous structure.

Kerui offers a variety of regular sizes to meet customer needs. Special shapes (e.g., hexagons, rectangles) cater to complex layouts.

Kerui offers different acid alkali resistant tiles price for each type.

Kerui offers a variety of regular sizes to meet customer needs. Special shapes (e.g., hexagons, rectangles) cater to complex layouts.

Kerui offers different acid alkali resistant tiles price for each type.

Kerui Customers to the Worldwide

Kerui acid-alkali resistant tiles ship worldwide and earn strong market praise. These tiles serve industries globally. Customers consistently report excellent performance. Industrial users praise their long-term lifespan. See more cases of acid & alkali resistant tiles here.

Extend The Service Life Of Acid Resistant Ceramic Tiles

Contact Kerui Refractory

Acid resistant tiles combine advanced material science with practical design to meet the demands of corrosive environments. From chemical plants to food processing units, their versatility and durability make them a cornerstone of industrial infrastructure. For tailored solutions, consult Kerui offering certified bricks and technical support to ensure optimal performance. See some videos on YouTube.