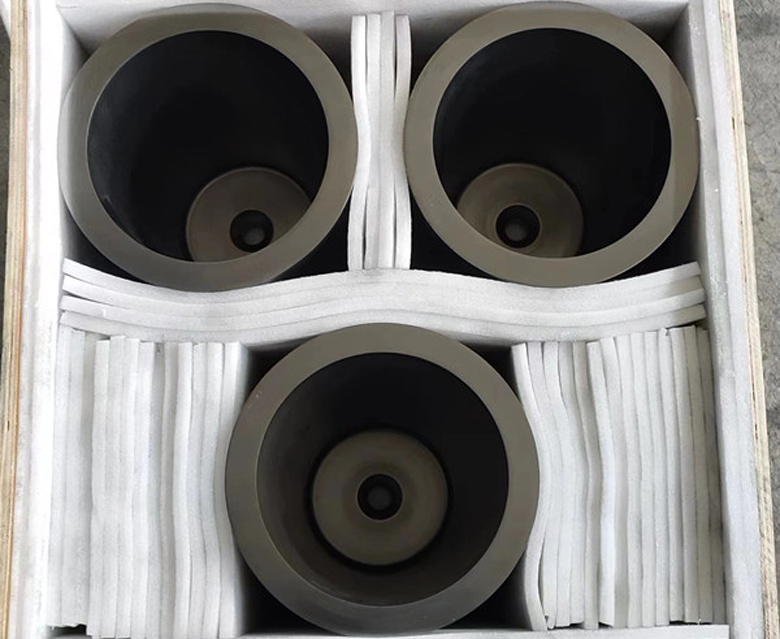

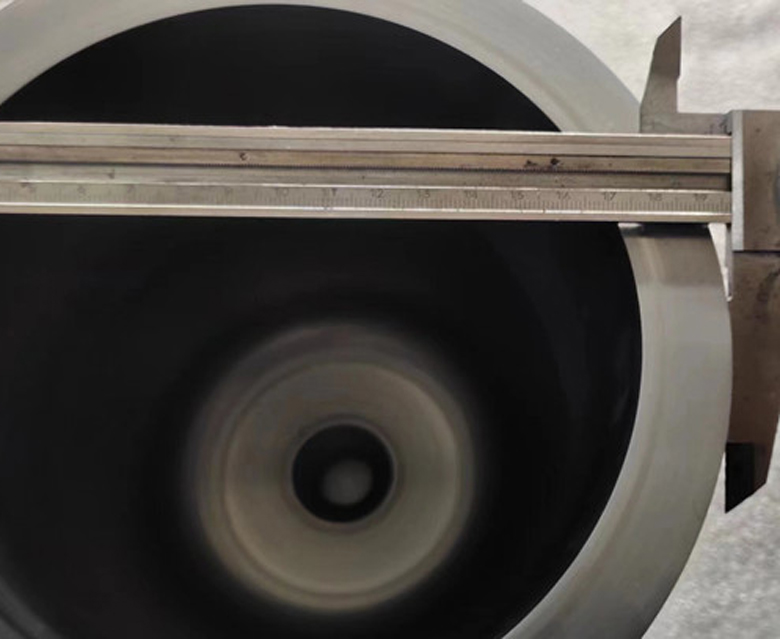

A batch of high-purity graphite crucibles is undergoing inspection. Once they pass the inspection, they will be shipped to Germany. This is container used for high-temperature melting and material processing. They offer better high-temperature resistance and chemical stability compared to ordinary materials.

Inspection Of High-purity Graphite Crucibles

High-purity graphite crucibles are widely used for melting and casting aluminum alloys. This product effectively maintains the purity of aluminum and preventing reactions with the crucible material. Once production is complete, we conduct comprehensive inspections of the products.

Why Choose High-Purity Graphite Crucibles?

High-purity graphite crucibles are composed of more than 99% carbon, binders, fluxes, and mineral additives. They possess outstanding properties:

- High-Temperature Resistance: High-purity graphite crucibles can remain stable at extremely high temperatures (typically exceeding 1500°C) without easily deforming or melting.

- Chemical Stability: In most chemical environments, graphite crucibles are resistant to reactions with other materials. This feature makes them suitable for melting various metals and alloys.

- Excellent Thermal Conductivity: The good thermal conductivity of graphite allows the crucibles to heat quickly and uniformly. This point makes them ideal for precise melting and casting processes.

- Low Expansion Coefficient: Their low expansion characteristics ensure that they do not undergo significant deformation at high temperatures. It helps to maintain the shape and quality of the molten metal.

Why Do Customers Choose Kerui Refractory?

- Customized Services: Kerui Refractory provides more targeted products and solutions based on the evolving needs of our customers.

- Technical Support and Training: We offer regular technical support and training to help customers make the most of our products and improve production efficiency.

- Continuous Quality Monitoring: Kerui Refractory maintains close communication with customers and continuously monitor product quality to ensure compliance with their strict production standards.

In Germany, due to the strict requirements for high-purity materials, high-purity graphite crucibles are widely used in metal melting. It covers multiple stages from initial melting to final casting. Their superior performance not only enhances production efficiency but also ensures high quality in the final silicon carbide crucible and other crucibles. Based on the current satisfaction, customers are confident in continuing to work with us.