In September 2025, a batch of Kerui 65% high alumina bricks completed final quality inspection and packaging, officially departing China for Indonesia. This batch, custom-made for a new incinerator project at an Indonesian energy company, includes conventional rectangular bricks, axe refractory bricks and corner refractory bricks in key locations, intended for use in the lining of the middle and lower sections of the incinerator shaft.

Precise Matching of Conventional and Corner Bricks in Indonesia

This delivery includes not only standard-sized T-series conventional rectangular bricks, axe bricks but also R-series corner bricks custom-made according to the customer’s incinerator design drawings. This combination demonstrates Kerui’s expertise in refractory applications.

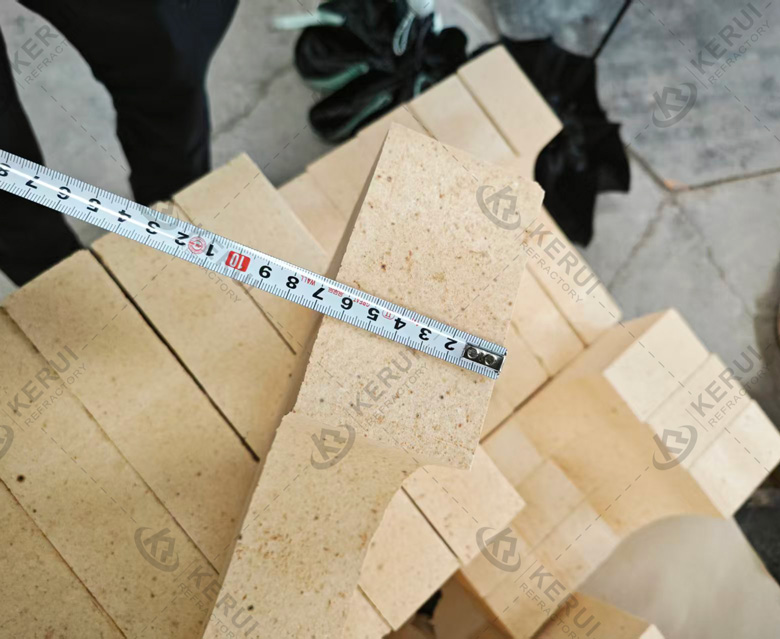

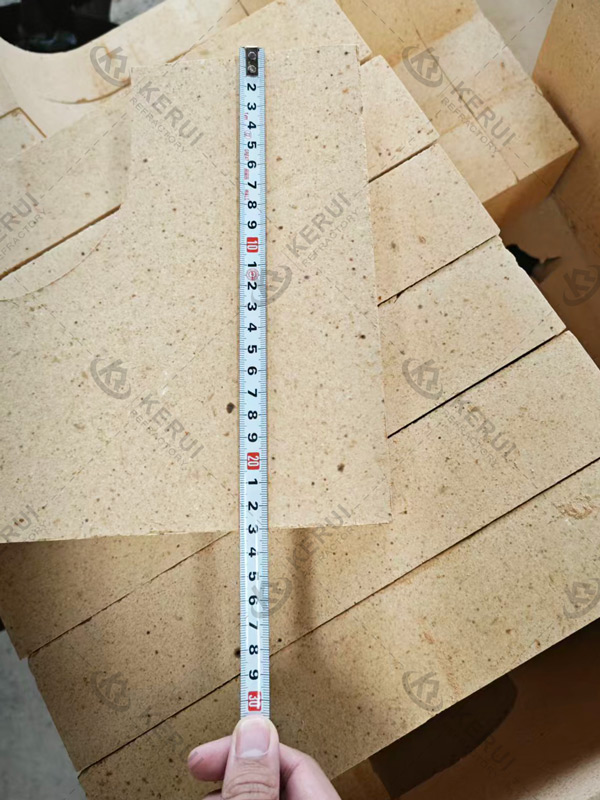

- High-Precision Conventional Bricks: All rectangular high alumina bricks are formed under high pressure using an automated hydraulic press, with dimensional tolerances strictly controlled within ±1mm. This exceptional dimensional accuracy ensures that brick joints are kept to a minimum of 1.5mm during laying. Filled with specialized refractory slurry, this creates a dense, uniform, and integrated lining, significantly reducing the penetration of hot melt and corrosive gases through the brick joints.

- Customized Corner Bricks: Transition areas and corners within incinerator are stress concentration points and weak links in traditional masonry methods. Kerui’s prefabricated corner bricks achieve seamless masonry at these corners, eliminating structural defects caused by on-site cutting. This not only enhances the structural integrity of critical furnace sections, but also significantly improves on-site construction efficiency and shortens the construction period.

Deep Collaboration With Indonesia: Optimizing Solutions Together

This delivery also includes high-precision conventional rectangular bricks, axe refractory bricks and customized corner bricks. Unlike the first collaboration, this time the technical exchange was more efficient and in-depth. Building on the successful collaboration over the past few years, both teams have a deeper understanding of each other’s technical standards and requirements.

- Continuous Product Optimization: Based on actual operating data from the previous generation of incinerators provided by the customer, Kerui’s technical team fine-tuned the matrix of this batch of bricks, further optimizing their corrosion resistance and achieving an iterative upgrade.

- Seamless Service Integration: As a long-term partner, we have established a smooth collaborative process across all aspects, from order confirmation and production scheduling to logistics and shipment. Kerui‘s provided “Masonry Instructions” were also tailored to the client’s construction team’s needs, ensuring maximum product value.