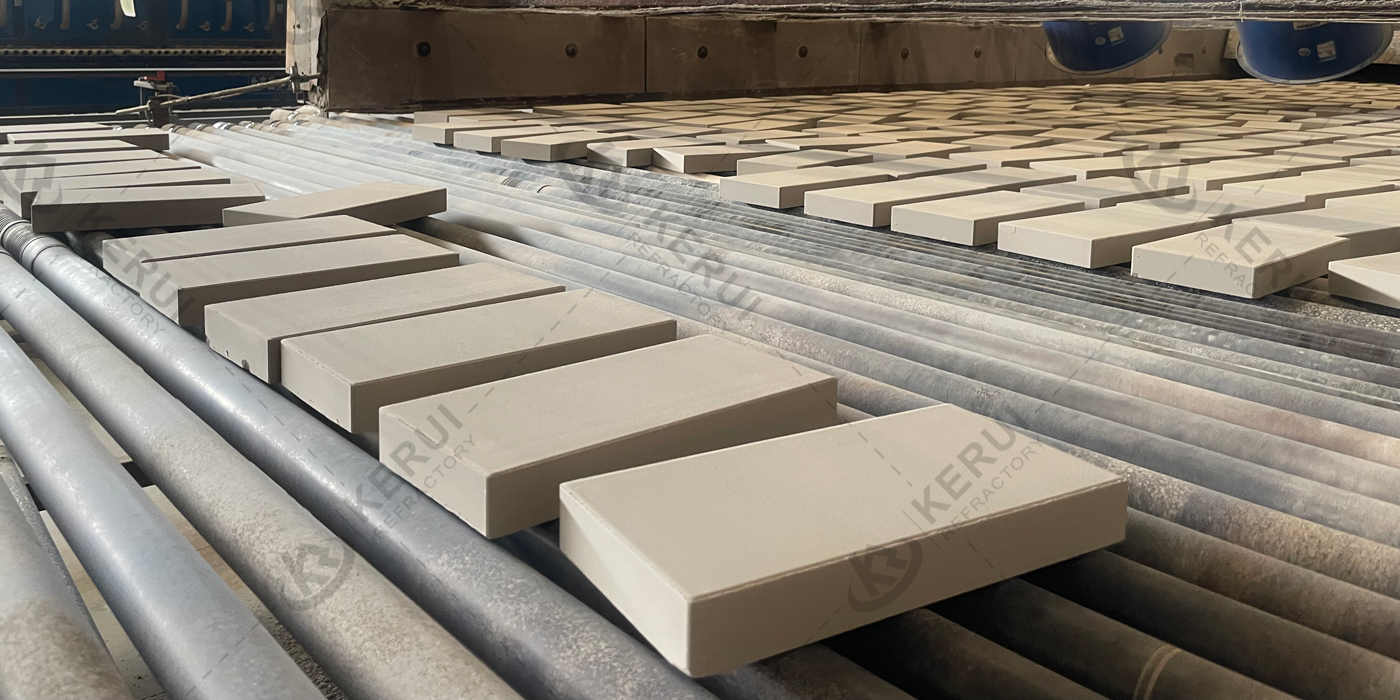

In July 2025, China’s leading anti-corrosion material manufacturer Kerui recently completed a batch of acid resistant tiles exported to South Korea. The specifications of this batch of products are 230×113×25mm, with excellent acid resistance. These bricks can resist 98% concentrated sulfuric acid corrosion. And they are equipped with high-strength furan resin mortar, which is suitable for highly corrosive environments in chemical, electroplating, pharmaceutical and other industries.

Benefits and Quality Control of Acid Resistant Tiles Shipped to South Korea

The acid resistant tiles being exported are made from high-purity quartz, feldspar, and special clay. After testing by the testing center, they have been found to have an acid resistance of 99.8%. This meets Korean standards. The accompanying furan adhesive is fast-curing and highly durable. It ensures the tiles can perform reliably in highly acidic environments over the long term.

To guarantee quality, Keri conducts several tests on every batch of tiles, including checks on dimensional tolerance, water absorption, and thermal shock resistance. A complete third-party test report is provided to meet the rigorous procurement requirements of our Korean customers.

Smooth Logistics and Customs Clearance Process

This batch of goods will be shipped in July 2025 by container shipping. It has now arrived at the customer’s warehouse. Keri works closely with Korean customers to complete Korean safety standards and customs declaration in advance to ensure smooth customs clearance of goods.

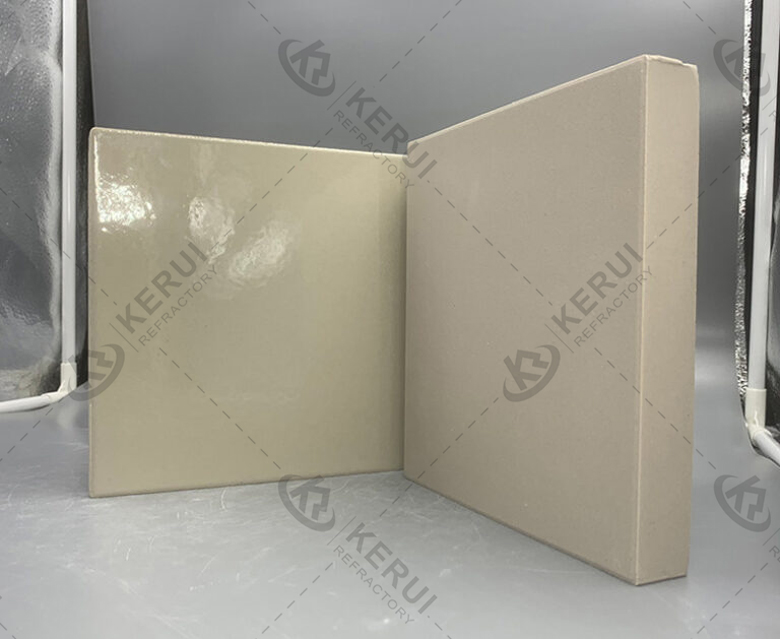

Choosing Between Glazed and Unglazed Acid Resistant Tiles

| Characteristic | Glazed Acid Resistant Tiles | Unglazed Acid Resistant Tiles |

| Surface Treatment | Glazed surface (vitreous glaze layer, 0.2-0.5mm thick) | Direct sintering, porous and rough surface |

| Firing Process | Double firing (bisque firing + glaze firing) | Single firing |

| Microstructure | Glaze layer seals pores (water absorption ≤0.1%) | Open pores (water absorption 0.5-2%) |

| Performance | Acid-impervious (even to 98% H₂SO₄); >95% smoothness retention, easy-clean; Good thermal shock resistance. |

Relies on body material’s acid resistance; High wear resistance with excellent anti-slip properties; Excellent thermal shock resistance. |

| Applications | Strong acid environments: e.g. 98% sulfuric acid tank linings, electrolytic cell linings. High hygiene requirements: e.g. pharmaceutical clean rooms, food acid-washing lines. Easy-clean scenarios: e.g. chemical plant floors (frequent washing areas). |

Media containing solid particles: e.g. acid sludge treatment tanks, mine acid leaching tanks. High thermal fluctuation environments: e.g. metallurgical acid regeneration furnaces (>200℃/h temperature variation). Secondary processing scenarios: e.g. corrosion protection projects requiring resin impregnation./td> |

Conclusion

Facing the challenge of strong acid corrosion environment, Kerui‘s acid resistant tile solution has passed the Korean KS certification and completed localized delivery verification. We will continue to provide customers with all-round support, including sample provision, third-party testing cooperation, exclusive solutions, etc.