Kerui Refractory proudly presents the 1260 ceramic fiber blanket, a high-performance insulation solution designed for extreme temperatures. Made with advanced technology, this blanket is perfect for industries requiring reliable thermal management.

- Classification Temperature: 1260ºC;

- Bulk Density: 96-160kg/m³;

- Length: 7200/3600mm/Customizable;

- Width: 600/610/1220mm/Customizable;

- Thickness: 6-60mm/Customizable;

- Package: Bag/Box/Customizable;

- Unit of Measurement: Roll/Square/Cubic;

- Certificate: ISO9001/ISO14001/OHSAS18001/CE/SGS;

Specifications of 1260 Ceramic Fiber Blanket

| Item | Common Type | Standard Type | High Purity Type |

|---|---|---|---|

| Classification Temperature, ℃ | 1050 | 1260 | 1260 |

| Service Temperature, ℃ | <1000 | 1050 | 1100 |

| Bulk & Density, kg/m³ | 96-128 | 96-128 | 96-128 |

| Permanent Liner Change, % | -4 (1000℃) | -3 (1000℃) | -3 (1100℃) |

| Heat Conductivity Coefficient, W/(m·k) (Bulk Density 128kg/m³) | 0.09 (400℃) 0.176 (800℃) | 0.09 (400℃) 0.176 (800℃) | 0.09 (400℃) 0.176 (800℃) 0.22 (1000℃) |

| Strength of Extension, Mpa | 0.08-0.12 | ||

| Al2O3, % | 44 | 46 | 47-49 |

| Al2O3+SiO2, % | 96 | 97 | 99 |

| Al2O3+SiO2+ZrO2, % | - | - | - |

| ZrO2, % | - | - | - |

| Fe2O3, % | <1.2 | <1.0 | 0.2 |

| Na2O+K2O, % | ≤0.5 | ≤0.5 | 0.2 |

| Size, mm | Standard Size: 7200/3600*610/1220*6-60; Customized Sizes | ||

Kerui 1260 Ceramic Fiber Blanket is Reliable High-Temperature Insulation

The 1260 ceramic fiber blanket is crafted using a special double-sided needling process. This ceramic fiber wool is made from high-quality ceramic fiber bulk, ensuring durability and efficiency.

- Color & Texture: White, smooth surface, no adhesives, asbestos-free and harmless.

- Performance: Lightweight, flexible, and highly stable.

Essential Features of Kerui 1260 Ceramic Fiber Blanket

- High Strength: Superior mechanical and structural strength.

- Thermal Insulation: Low thermal conductivity and excellent heat capacity.

- Durability: Resistant to thermal shock and chemical stability.

- Versatility: Available in various densities and thicknesses.

- Installation: Easy to install, no curing or drying required.

- Energy Efficiency: Ideal for industries aiming to improve energy efficiency.

Kerui Ceramic Fiber Blanket Production Line Stands Out

- Advanced Technology

Utilizes cutting-edge “blown” and “spun” processes for high-quality fiber production.

The double-sided needling process enhances strength and durability. - High Production Capacity

Over 10 ceramic fiber production lines with a daily output of 4000 m³.

Ensures timely delivery for large-scale orders of ceramic fiber products. - Consistent Quality

Strict quality control measures at every stage of production.

Uniform density and thickness across all blankets. - Customization Options

Offers a wide range of densities and thicknesses to meet specific customer needs.

Flexible packing and shipping solutions, including OEM services. - Durability & Performance

Resistant to thermal shock, chemical corrosion, and high temperatures.

Maintains structural integrity in extreme conditions. - Eco-Friendly Production

Completely inorganic materials, no harmful fumes or smoke.

Compliance with international environmental standards (REACH, CE).

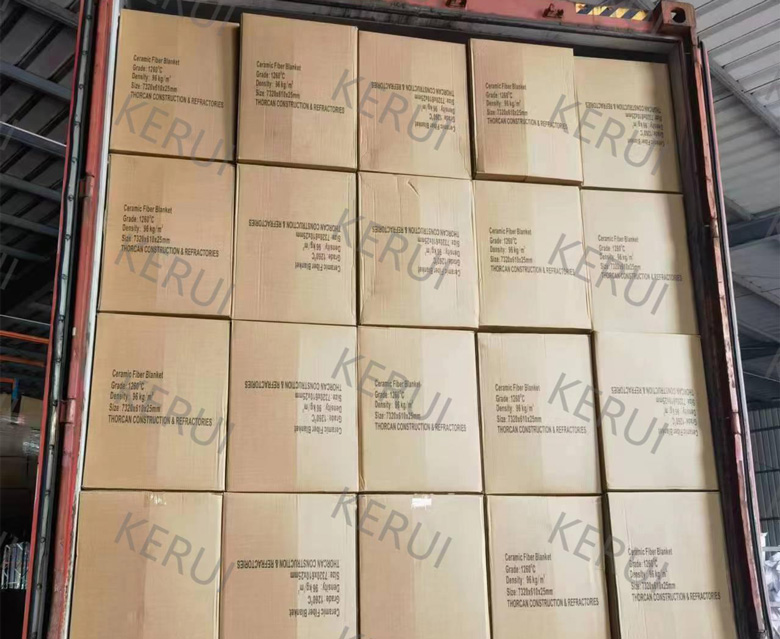

Efficient Packing and Reliable Delivery

- Standard Packing: Plastic bag inside, woven bag or carton outside.

- Custom Options: Wooden pallets or OEM packaging available.

- Efficient Shipping: Fast delivery with flexible logistics.

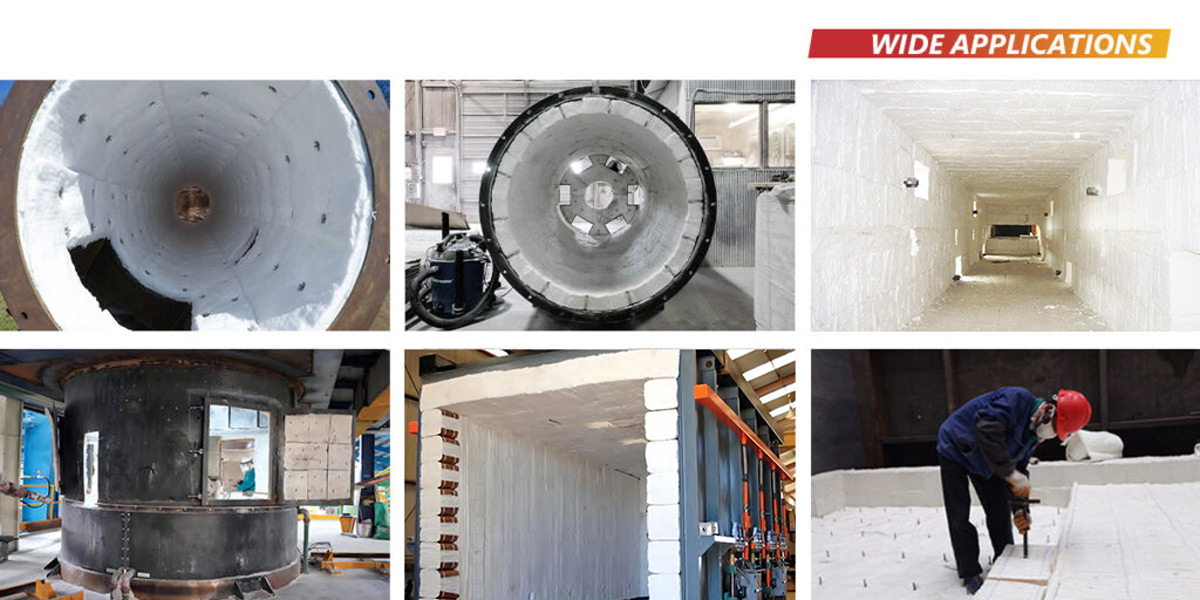

Kerui 1260 Ceramic Fiber Blanket for Diverse Industrial Applications

The ceramic fiber blanket 128kg m³ is widely used in industries requiring high-temperature insulation:

- Industrial Furnaces: Lining for kilns, annealing furnaces, and ladle covers.

- Expansion Joints: Filler for high-temperature expansion joints.

- Pipe Insulation: Ideal for duct and pipeline insulation.

- Fire Protection: Used in fireproofing and heat shields.

- Aerospace & Petrochemicals: Insulation for reactors, boilers, and heat exchangers.

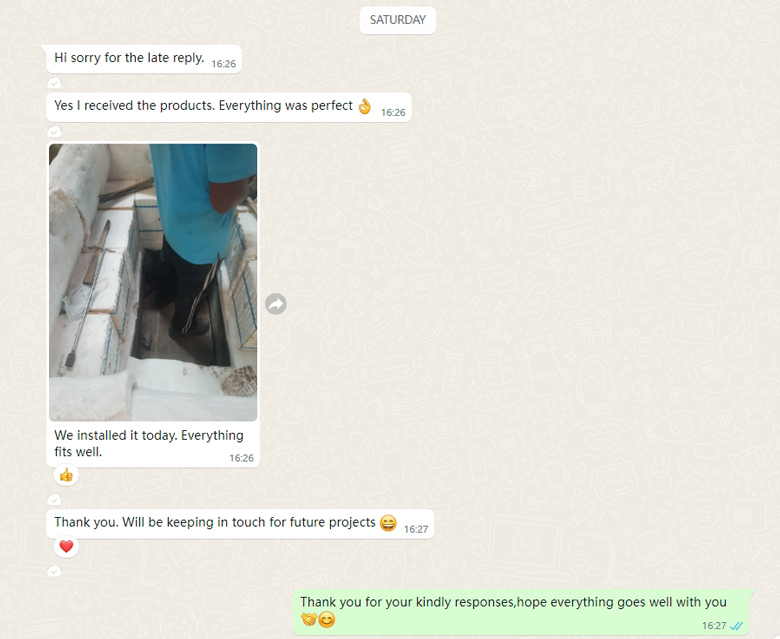

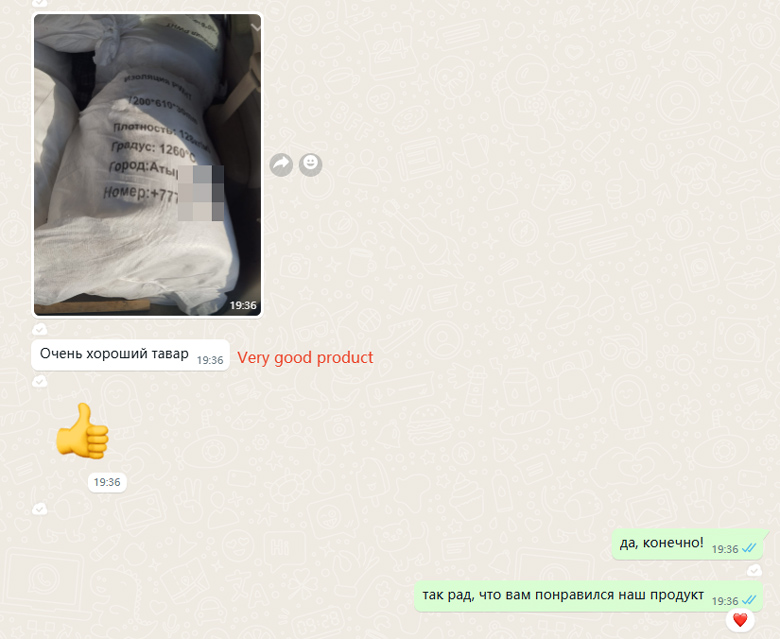

Reviews of Kerui Customers

Kerui’s partners have provided highly positive feedback on our product quality and services.

- Extended Furnace Life: The service life of refractory materials increased from 6 months to 12 months, reducing equipment downtime by 50%.

- Reduced Energy Consumption: Furnace energy consumption decreased by 15%, saving approximately 5 million RMB annually.

Why Choose Kerui?

- Certified Quality: International certificates, including ISO, SGS, CE, ASTM, and so on.

- Advanced Production: Over 10 production lines, daily output of 4000 m³. See more videos on YouTube.

- Global Experience: 20+ years of export expertise.

- Custom Solutions: Tailored solution, packing and shipping options for customers.

Conclusion

The 1260 ceramic fiber blanket by Kerui Refractory is a reliable, high-performance solution for industries facing extreme heat challenges. With superior insulation, durability, and flexibility, it is the ideal choice for your thermal management needs. Contact Kerui Refractory today to learn more about our products and how we can support your business!