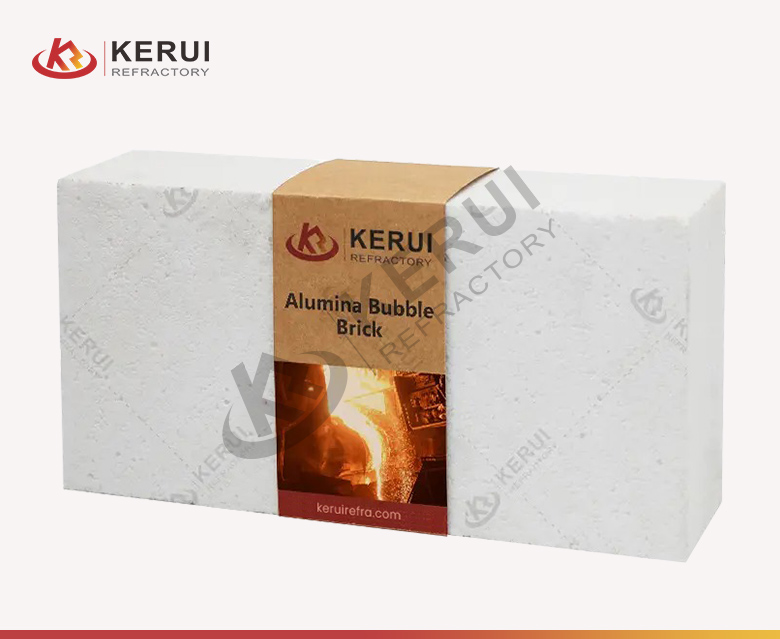

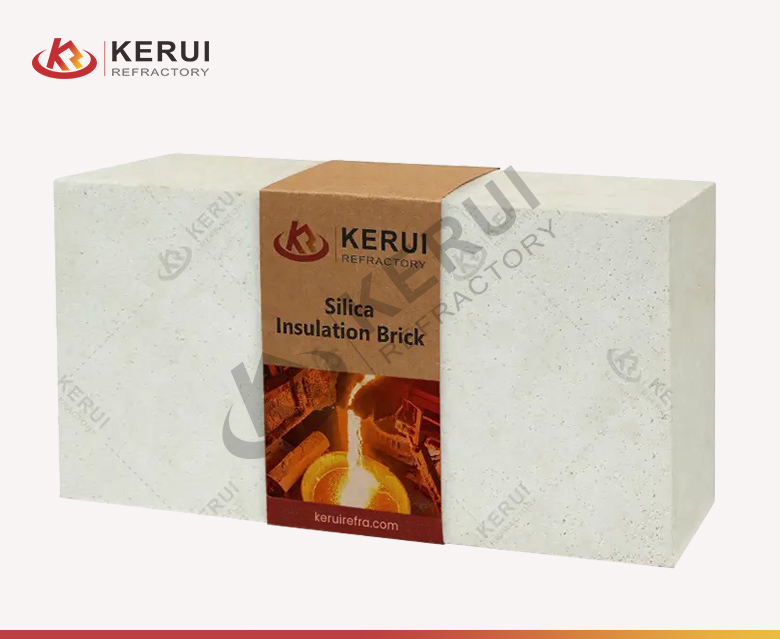

Refractory bricks for sale Kerui provide are for various types of kilns. We offer primarily two methods of calculation, including the number of pieces and weight (tons/kilograms). Please refer to a comprehensive list of refractory bricks for sale.

Note: The standard delivery time for products in stock is 15-30 days.

Kerui Factory for Manufacturing Refractory Bricks for Sale

Kerui factory boasts strong production capabilities and strict quality control standards.

- Area: 50,000 square meters factory;

- Production equipment: 2*168 meter tunnel kilns, over 40 presses, fully automatic batching system, over 100 kiln cars, and so on.

- Production workshops: batching workshop, production workshop, firing workshop, fully automated control workshop, chemical testing workshop, physical testing workshop, etc.

- Team: production, quality control, packaging, shipping, and so on.

Different Manufacturing Process of Refractory Fire Bricks for Sale

Kerui offers various production processes to meet different customer needs, such as sintering, semi-sintering, casting, etc. Depending on the specific operating environment, customers can choose refractory bricks that are suitable for their processes.

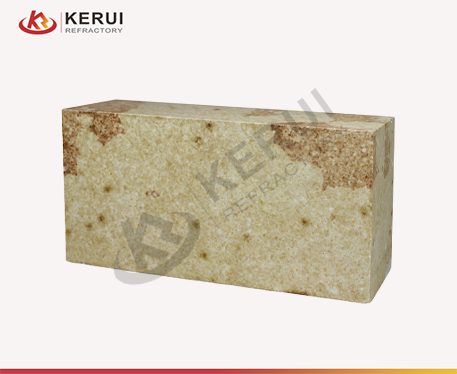

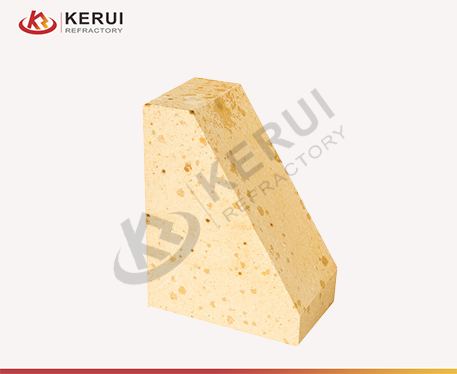

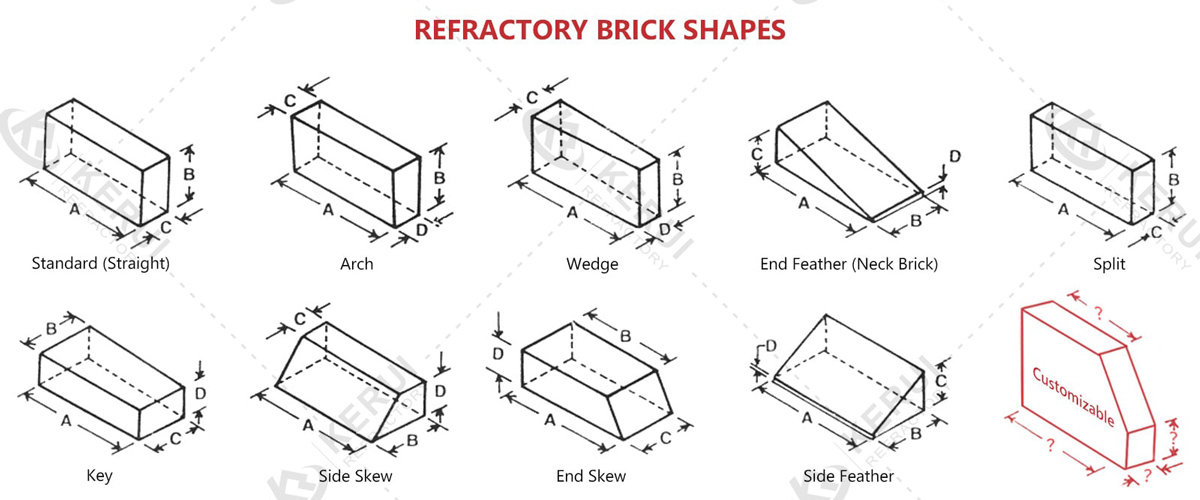

Shapes of Kerui Refractory Bricks for Sale

Kerui sells a variety of refractory bricks to meet the needs of different parts in high-temperature industries, including standard (230*114*65mm), end arch, side arch, wedge, key, side skew, end skew, side feather, end feather, split, straight, soap, jamb, neck, vdz shapes, ISO shapes, etc.

We offer a variety of refractory bricks for different parts of kilns, including converter bricks and rotary kiln bricks.

Solutions of Kerui Refractory Bricks for Sale

As a Chinese manufacturer and refractory expert, Kerui provides refractory solutions for various kilns for customers, including:

Blast furnaces, converter furnaces, electric furnaces, tunnel kilns, roller kilns, glass melting furnaces, vertical kilns, rotary kilns, calcining furnaces, coke ovens, and so on.

Kerui Services

- Quick response to your needs;

- Provide optimal refractory material solutions;

- Refractory brick quality testing;

- Team support: Technical guidance (including drawings and documents), delivery, packaging, shipping, construction, etc.;

- Comprehensive after-sales service support.

Other Complementary Refractory Products

When customers build or maintain high-temperature furnaces, they often need to consider multiple factors. Therefore, in addition to providing high-quality refractory bricks, we also offer a range of complementary products such as monolithic refractories, refractory anchors, acid-resistant bricks, and ceramic fibers. These products can be flexibly combined based on the customer’s furnace type, operating conditions, and specific needs, achieving optimal refractory performance and extending the furnace’s service life.

Cases Over the World

Contact Kerui Now

Whether you’re constructing a new high-temperature kiln or refurbishing an existing one, Kerui offers a comprehensive range of refractory brick solutions to meet your specific needs. Our extensive product line includes standard shapes, custom designs, and complementary materials to ensure optimal performance and longevity. More importantly, our team provides technical guidance, installation assistance, and reliable after-sales service. See more our latest news on Linkedin.