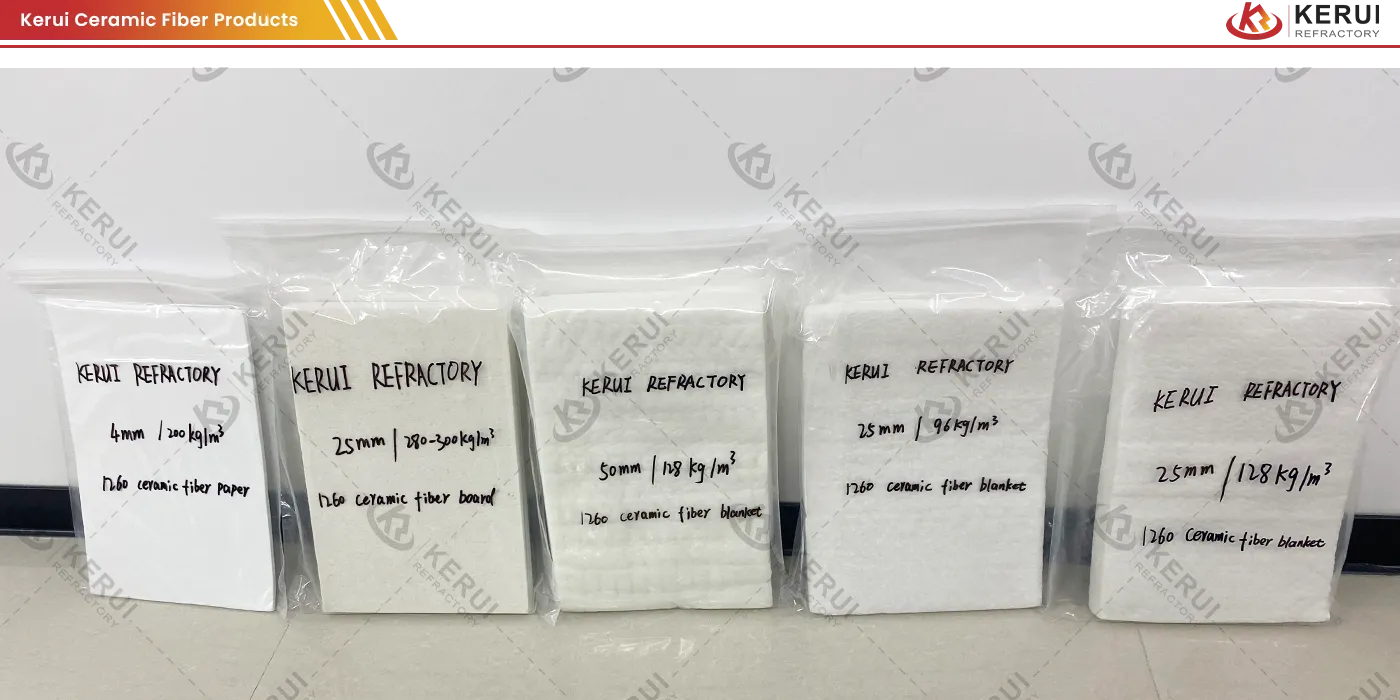

Kerui ceramic fiber products are high-performance thermal insulation materials widely used in high-temperature industries. Generally, classified by form, Kerui Refractory offers 10+ types of hot ceramic fiber products. If you have special needs, Kerui Refractory, as a manufacturer and supplier in China, offers customized products and customized insulation solution to 1000+ customers.

Kerui Ceramic Fiber Products for Sale

Bulk Density: 96-160g/cm³;

Classification Temp: 800-1450ºC;

Thickness: 6-60mm;

Bulk Density: 260-320g/cm³;

Classification Temp: 950-1430ºC;

Thickness: 3-100mm;

Bulk Density: 160-220g/cm³;

Classification Temperature: 1260-1430ºC;

Accessories: Anchors;

Bulk Density: 200-240g/cm³;

Classification Temperature: 1260-1350ºC;

Thickness: ≥1mm;

Bulk Density: 380-500g/cm³;

Classification Temperature: 650-1400ºC;

Size: Φ6-50mm;

Bulk Density: ≥500kg/m³;

Classification Temperature: 1000~1260ºC;

Thickness: ≥3mm;

Bulk Density: 100-300kg/m³;

Service Temperature: 1000-1280ºC;

Inner Diameter: 18-539mm;

Bulk Density: 230-253kg/m³;

Service Temperature: 650-1110ºC;

Thickness: 25-115mm;

Bulk Density: 96-160g/cm³;

Classification Temp: 800-1450ºC;

Thickness: 6-60mm;

Other Types

Bulk Density: 64-500g/cm³;

Classification Temperature: 1100ºC;

Thickness: ≥1mm;

Bulk Density: 150-250kg/m³;

Service Temperature: 1600ºC;

Thickness: 25-115mm;

Size of Kerui Ceramic Fiber Products

Kerui provides the following types of services for ceramic fiber products:

Hot regular size: Regular size can usually meet the needs of most customers. And regular size spot inventory is relatively sufficient.

Customized size: Kerui Refractory can provide customized size products according to customer needs. There will be differences in price, production cycle and packaging plan.

Key Features of Kerui Ceramic Fiber Products

-

Low Thermal

Conductivity

Excellent High Temp

Resistance

Lightweight And

Energy-Saving

Excellent Thermal

Stability

-

Strong Chemical

Stability

Adaptable To

Various Forms

Environmentally

Friendly

Easy To

Construct

Strict Quality Control of Kerui Ceramic Fiber Products

Welcome to Visit Kerui Factory

This video shows Kerui’s ceramic fiber products. Including product display, factory production process, inspection, packaging and delivery process. We can arrange delivery according to the customer’s project time.

Note: This video mainly shows ceramic fiber blanket. If you want to know more, please contact us.

Professional Packaging and Shipping of Kerui Ceramic Fiber Products

Kerui’s Packaging Advantages

Woven Bags

Moisture-proof woven bags: Can prevent moisture during transportation;

Corrugated Boxes

Corrugated boxes: Equipped with moisture-proof plastic bags inside;

Customized Packaging

Customized packaging: Customized packaging that meets customer needs.

Kerui’s Shipping Strengths

Global Coverage

Ships to 60+ countries via air, sea, and land. See some cases.

Fast Delivery

Priority routes for urgent orders, with real-time tracking updates.

Cost Control

Flexible LCL/FCL options and partnerships with trusted logistics providers.

Industrial Applications of Kerui Ceramic Fiber Insulation Products

- Lining for Electric Arc Furnaces

- Ladles and Tundishes

- Lining of Blast Furnaces

- Rotary Kilns:

- Preheaters and Coolers

- Glass Melting Furnaces

- Regenerators

- Cracking Furnaces

- Reformers

- Lining for Aluminum Smelters

- Copper Refining Furnaces

- Tunnel Kilns

- Shuttle Kilns

Project Sites of Kerui Customers Over World

Kerui Refractory serves customers in over 50 countries across five continents. Our customers are located in the Middle East, Southeast Asia, Europe, North Africa, Latin America, and so on. See more cases here. See their projects and reviews:

Kerui’s Packaging Advantages

Kerui’s Packaging Advantages Kerui’s Shipping Strengths

Kerui’s Shipping Strengths