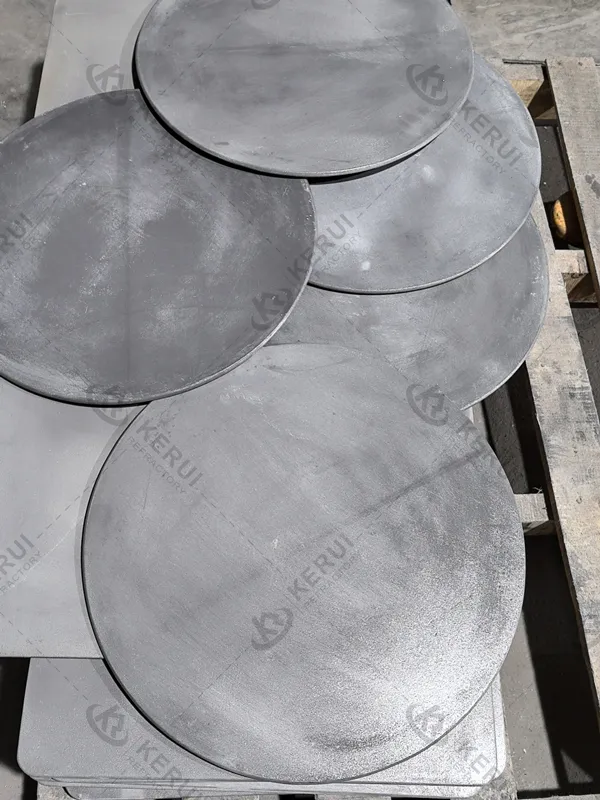

Silicon Carbide Plate

Silicon carbide plate is a high-temperature, lightweight ceramic material primarily composed of silicon carbide. Kerui offers these materials: OBSIC, SiSiC/RBSiC, RSiC, NSiC, SSiC. Kerui provides high-performance and high-quality plates at factory prices. Additionally, we support customized solutions. We have successfully cooperated with over 1000 customers.

- Free Sample:

- Available

- Document:

- Certificates supporting

- Performance Test:

- Support

- Shipment:

- 7-15 working days

Sizes and Shapes of Kerui SIC Plates

Kerui provides a comprehensive range of silicon carbide plates, including solid, shed, and hollow plate options. We can also customize silicon carbide kiln shelves to your exact specifications to meet the unique demands of your application.

| 370*500*11 | 400*450*10 | 400*420*10 | 400*500*11 |

| 400*550*12 | 400*600*12 | 400*650*12 | 420*450*10 |

| 450*500*12 | 480*500*12 | 500*500*12 | 500*520*12 |

| 500*550*12 | 500*600*13 | 500*700*14 | 560*800*15 |

| 600*660*15 | 600*700*14 | 600*720*17 | 600*770*15 |

| 600*800*15 | 610*700*14 | 620*620*20 | 620*680*15 |

| 630*720*17 | 650*720*17 | 800*800*20 | 800*1000*20 |

Materials of Kerui Silicon Carbide Plates

As a manufacturer, Kerui Refractory mainly provides the following five types of refractory silicon boards from which customers can choose. Different materials have different operating temperatures and working conditions. Kerui can recommend silicon carbide shelves according to the customer’s situation.

| Types | Classification Temperature |

|---|---|

| Oxide-Bonded Silicon Carbide Plate (OBSIC) | 1400°C |

| Reaction Bonded Silicon Carbide Plate (RBSiC/SiSiC) | 1380°C |

| Nitride-Bonded SiC Plate (NSiC) | 1550°C |

| Recrystallized silicon carbide Plate (RSiC) | 1650°C |

| Sintered Silicon Carbide (SSiC) | 1650-1950°C |

Basic Data of Kerui Silicon Carbide Plates

| Item | Index | |

|---|---|---|

| SIC Chemical Composition, % | ≥ | 90 |

| Max.Service Temp, °C | 1400 | |

| Refractoriness, SK | ≥ | 39 |

| 2kg/cm² Refractoriness Under Load, kg/cm² | ≥ | 1650 |

| Modulus of Rupture at Room Temp, kg/cm² | ≥ | 500 |

| Modulus of Rupture at 1400°C, kg/cm² | ≥ | 100 |

| Compressive Strength, % | ≥ | 1300 |

| Thermal Expansion at 1000°C , % | 0.42 -0.48 | |

| Apparent Porosity, % | 7-8 | |

| Bulk Density, g/cm² | 2.70 -2.75 | |

| Thermal Conductvity at 1000°C, kcal/m.hr. °C | 13.5-14.5 | |

Note: This is the parameter of a regular oxide-bonded silicon carbide plate. If you need other types of plate accommodation, please contact us.

![]()

Key Features of Kerui Silicon Carbide Sheets

Withstands temperatures up to 1650°C;

Excellent thermal conductivity;

Enables rapid heating/cooling applications;

Good thermal stability;

Low coefficient of thermal expansion maintains stability under thermal cycling.

Hardness second only to diamond;

Exceptional wear resistance;

High resistance to most acids;

Reduces structural load and facilitates handling.

![]()

| Categories | Sintered Silicon Carbide | Reaction Bonded Silicon Carbide | Hot Pressed Silicon Carbide | Hot Isostatic Pressed Silicon Carbide | Recrystallized Silicon Carbide |

|---|---|---|---|---|---|

| Density | Wide range | High | High | Very high | High |

| Mechanical Properties | Wide range | Good | Excellent | Excellent | Excellent |

| High-temperature Resistance | Wide range | Good | Excellent | Excellent | Excellent |

| Corrosion Resistance | Wide range | Good | Excellent | Excellent | Excellent |

| Production Cost | Low | Medium | High | High | Medium |

| Grain Size | Wide range | Fine | Fine | Fine | Large |

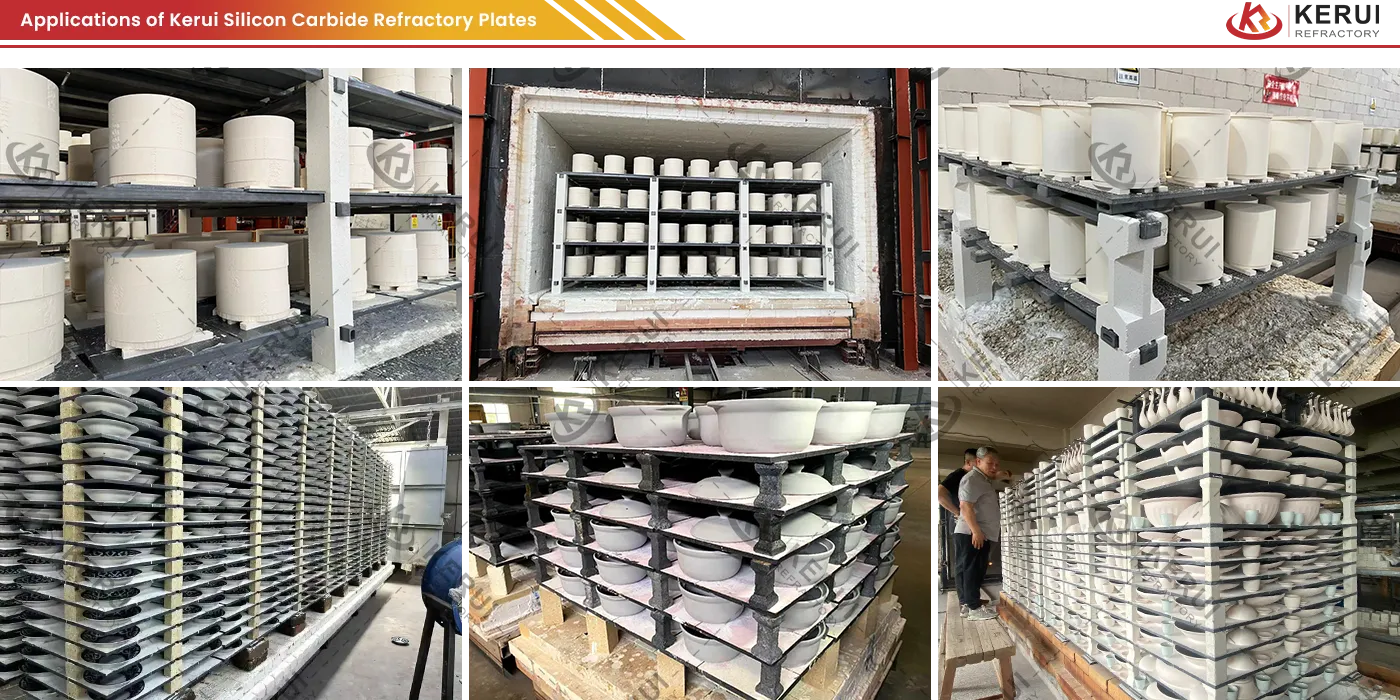

Applications of Silicon Nitride Plates

Kiln shelves are essential refractory components designed to withstand extreme temperatures and harsh industrial environments. Primarily, they serve as durable platforms within kilns and furnaces, supporting the materials or products being processed.

Equipment: Ceramic kilns (roller hearth, tunnel, periodic).

Equipment: Heat treatment furnaces, Metallurgical furnaces;

Equipment: Glass furnaces (lehrs, tempering furnaces, sag molds).

Equipment: Refractory material kilns.

Equipment: High-temperature sintering furnaces.

Equipment: Chemical industry furnaces, reactors, calciners.

Kerui Silicon Carbon Plates Applied to the World

Kerui Refractory proudly serves 1,000+ industrial partners across 50+ countries – from Russia and Southeast Asia (Philippines, Malaysia, etc.) to the Middle East (Turkey, Saudi Arabia, UAE, etc.) and North Africa (Morocco, etc.).

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

Choose Kerui Refractory as Your Silicon Carbide Refractory Plate Manufacturer

As an experienced manufacturer, Kerui Refractory offers more than just products. Many customers choose us because of the following advantages.

Quality Plates: Our customers appreciate our commitment to quality, as evidenced by our premium raw materials, refined manufacturing processes, and stringent quality assurance measures.

Factory Price: By eliminating the middleman, we are able to provide highly competitive factory-direct pricing.

Certificates: Kerui Refractory has a series of international certificates and patents. View the pictures.

Services: Our comprehensive services include customized design solutions, optimal shipping routes, and timely logistics updates, ensuring a seamless experience for our partners.