Kerui manufactures and supplies refractory castable all over the world. The castables’ construction method does not affect their shape or size. After the castable material solidifies, it forms a high-hardness refractory lining. Customers are advised to choose the appropriate castables for construction based on different types of characteristics. Kerui offers castable to 500+ customers around the world, including RUSAL, CHALCO, ALBA, POSCO, and PSM.

10+ Types of Kerui Refractory Castable for Sale

Heavy-duty Refractory Castable

Lightweight Refractory Castable

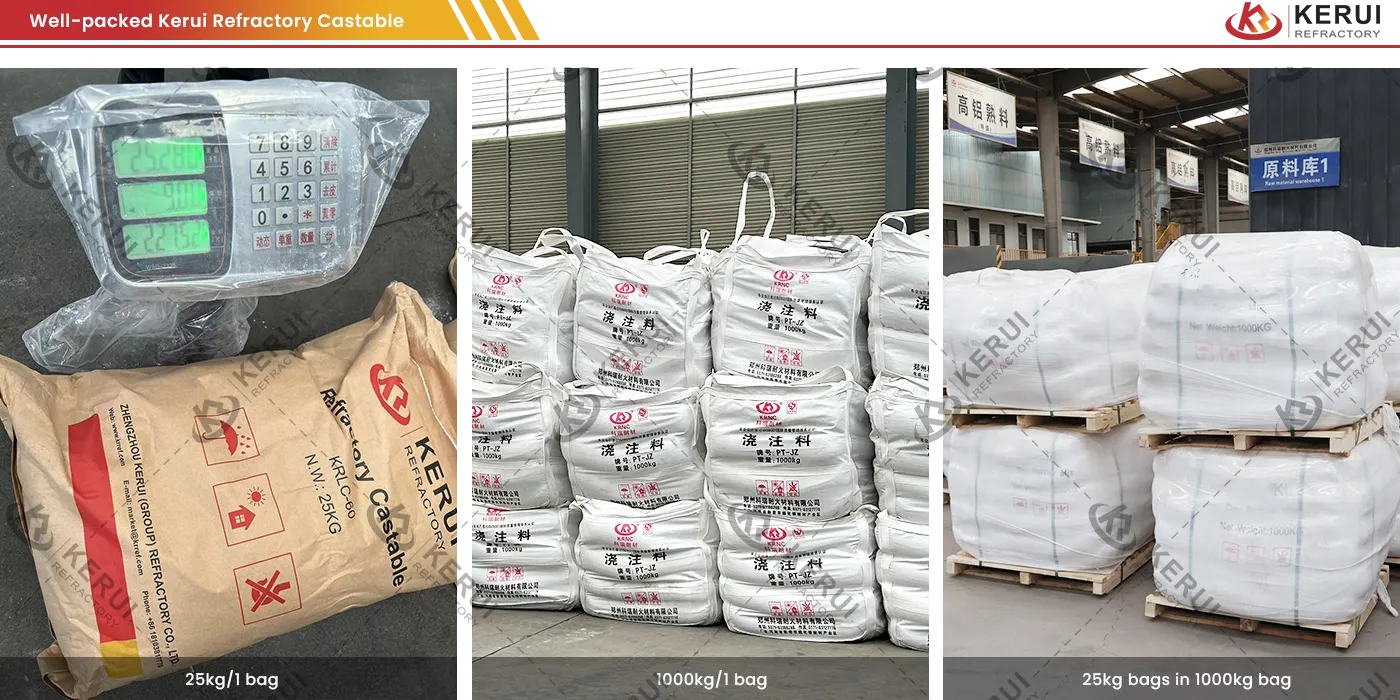

Different Packages of Kerui High Temperature Castable Refractory

Kerui understands that proper packaging is just as critical as the quality of high temp castable refractory itself. That’s why we provide flexible, durable, and customized packaging solutions designed to protect your monolithic materials during storage and transportation while meeting your specific operational requirements.

Minimizes handling frequency;

Cost-effective for bulk transportation.

Easy manual handling;

Better inventory control.

Protects inner bags during transit;

Simplifies storage and distribution.

Available in various sizes and configurations;

Special labeling available.

Features of Kerui Monolithic Castable Refractory

- High Temperature Resistance: Withstands 1,300°C to 1,800°C (2,372°F to 3,272°F).

- Thermal Shock Resistance: Resists cracking under rapid temperature changes.

- Abrasion & Corrosion Resistance: Protects against chemical attacks (e.g., slag, molten metal).

- Mechanical Strength: High compressive strength for structural stability.

- Fast Strength Development: Most castables have high early strength at room temperature.

- Good Integrity and Air Tightness: after casting, the integrity is strong, and there is almost no seam.

- Adjustable Mix Ratio, Customizable Performance: Different aggregates and binders can be selected according to the use requirements.

- Easy Installation: Can be poured, gunned, or troweled into place.

Strict Quality Control of Kerui Refractory Castable for Sale

Unlike traditional refractory bricks, castables offer superior installation flexibility, better thermal resistance, and longer service life.

Industrial Applications of Refractory Bricks

Refractories castable, refractory coatings, and refractory prefabricated components have extensive applications in many industries.

Using part: They are commonly used for lining high-temperature equipment such as furnace linings, furnace doors, chimneys, furnace covers, outlet pipes, wear repair areas, and insulation layers. Additionally, they are widely used in the construction of refractory structures.

- Lining for Electric Arc Furnaces

- Ladles and Tundishes

- Lining of Blast Furnaces

- Rotary Kilns:

- Preheaters and Coolers

- Glass Melting Furnaces

- Regenerators

- Cracking Furnaces

- Reformers

- Lining for Aluminum Smelters

- Copper Refining Furnaces

- Tunnel Kilns

- Shuttle Kilns

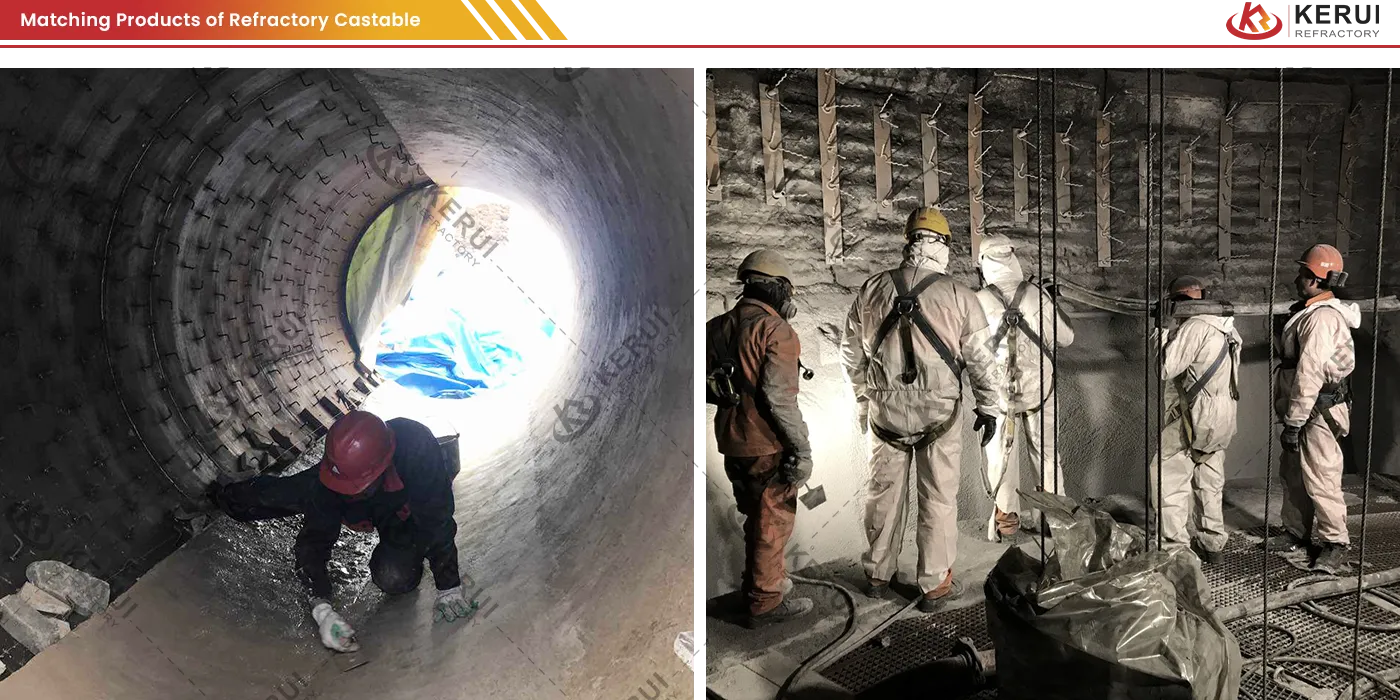

Matching Products for Use

In practical applications, cast refractory often needs to work with other refractory materials or accessories. This ensures structural stability, sealing performance, and long-term durability. Here are common matching solutions:

- Refractory Bricks;

- Refractory Cement;

- Anchors & Fixings;

Kerui offers a complete refractory material solution. Our products include high-quality refractory castable material, bricks, cement, and anchors. They ensure stable equipment operation and easier maintenance. Kerui meets all your needs, whether for new projects or repair work. You can rely on us with full confidence!

Factory Castable Refractory Price from Kerui Refractory

The Kerui refractory castable price is dependent on factors such as product composition, manufacturing process, quantity, and customization requirements. However, we are the original refractories manufacturers in China with strong production capabilities and comprehensive product support services. Importantly, we offer competitive prices. If you are interested in our products and solutions, please provide us with your detailed requirements.

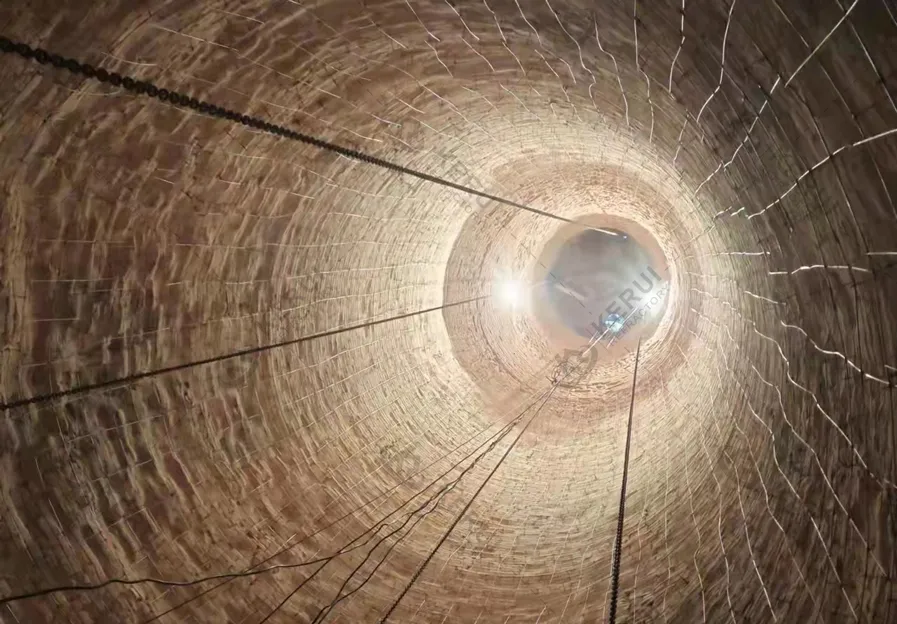

Refractory Casting Castable Project Sites Around the World

Kerui Refractory has earned the trust of industrial leaders worldwide, with a proven track record across the Middle East, Southeast Asia, Europe, North Africa, Latin America, and beyond. Our long-term partnerships with major corporations, including RUSAL, CHALCO, ALBA, POSCO, and PSM.

These cooperation cases demonstrate our unwavering commitment to quality, innovation, and reliability in refractory solutions.