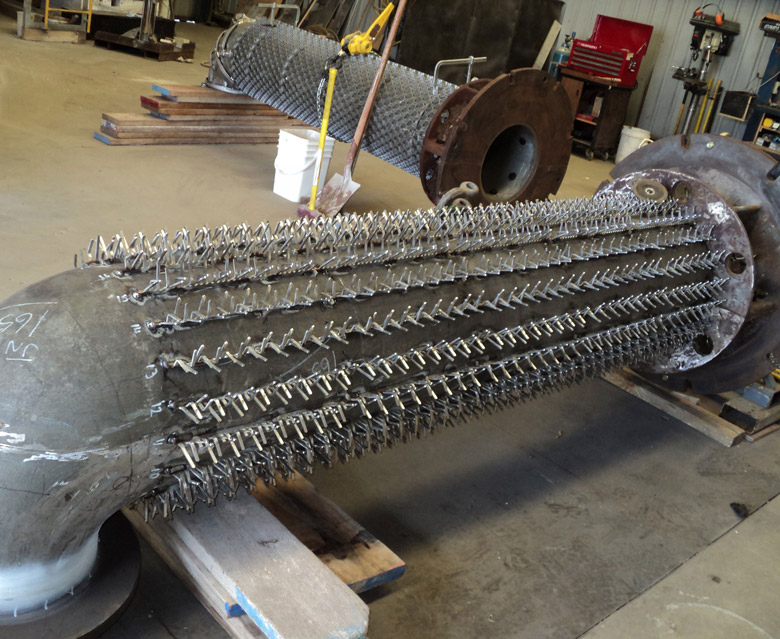

Refractory anchors are used to connect the inner parts with the furnace body and shell of high-temperature equipment. They can prevent the refractory materials shirk or cracking in high-temperature situations. And they can be used in a wide temperature range from 500℃ to 1400℃.

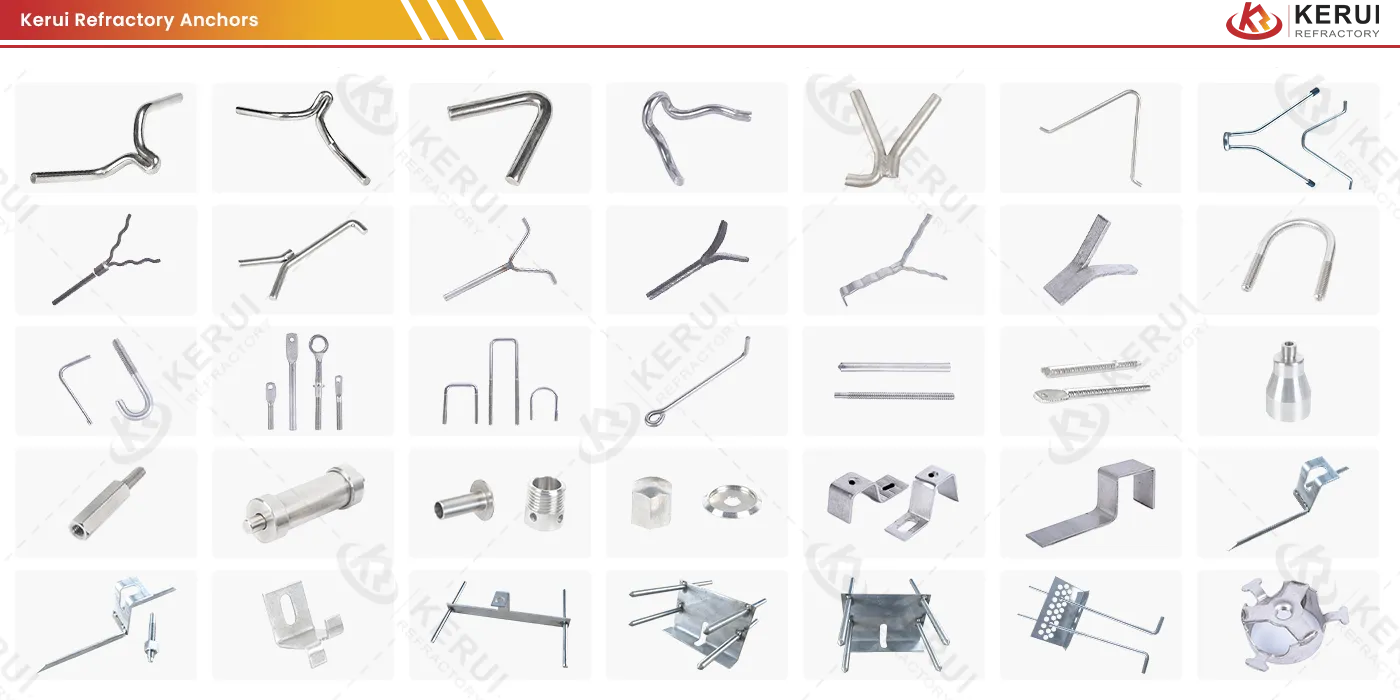

- Shapes: Y-anchor, V-anchor, U-anchor, S-anchor, T-anchor, wavy anchor;

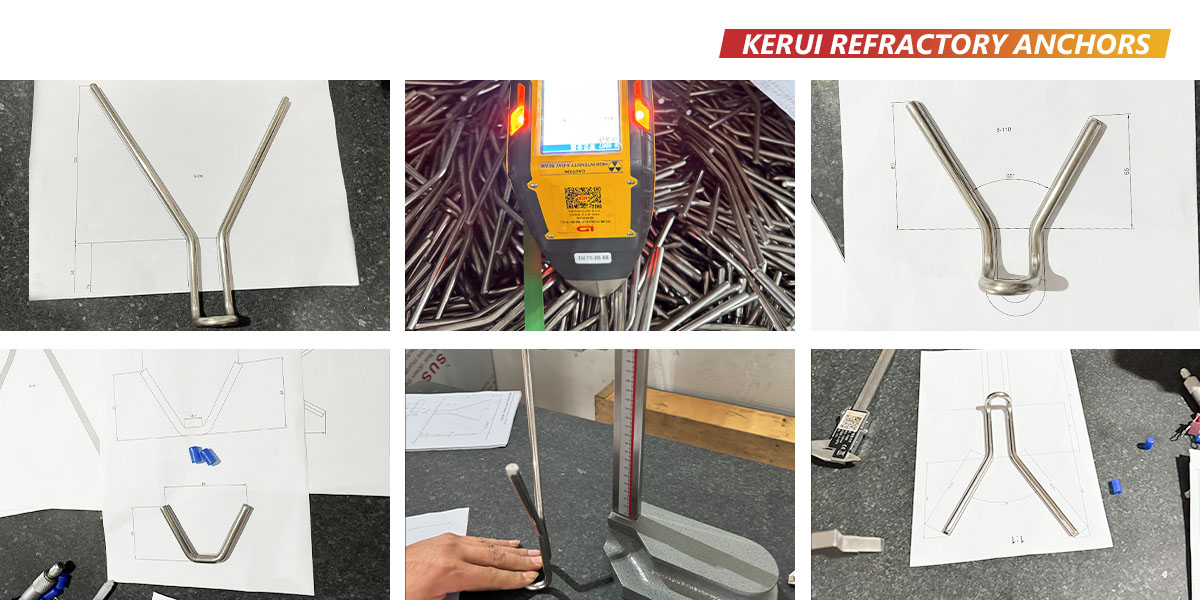

- Materials: SUS201, SUS 304, SUS 310S, ceramic, etc;

- Service Temperature: 500℃ to 1400℃;

- Delivery: 7-30 Working Days;

- Price: Low Ex-factory Price;

Different Types of Kerui Refractory Ceramic Anchors

There are different shapes of stainless steel refractory anchors. They can be used in different situations in high-temperature kilns.

- By Shapes: Y type anchors, refractory V anchors, U-anchor, S-anchor, T-anchor, wavy refractory anchors, and so on.

- By Applications: Castable anchors, ceramic fiber anchors, fabricated assemblies, fasteners/threaded parts, ifb/firebrick hangers & tie backs, precast components, etc.

- According to the installation method: Cast‑in‑place anchors, mechanical expansion anchors, undercut anchors, adhesive / bonded anchors, etc.

Textures of Refractory Anchors

Kerui Refractory provides several types of anchors. They are made by different refractory products, including low carbon steel, silicon steel, ferrochrome, ferrochrome, type 320 stainless steel, ceramic, etc.

NO.1 Metal anchors can withstand 900-1200℃.

- low carbon steel: 450℃;

- Q235, SUS201 ≤550℃;

- SUS 304: 550℃-1000℃;

- SUS 310S: 1000℃-1250℃;

NO.2 Heat-resistant steel and ceramic composite can withstand 1250℃-1400℃.

NO.3 Ceramic anchors (clay, high alumina, corundum) can withstand 1650-1800℃.

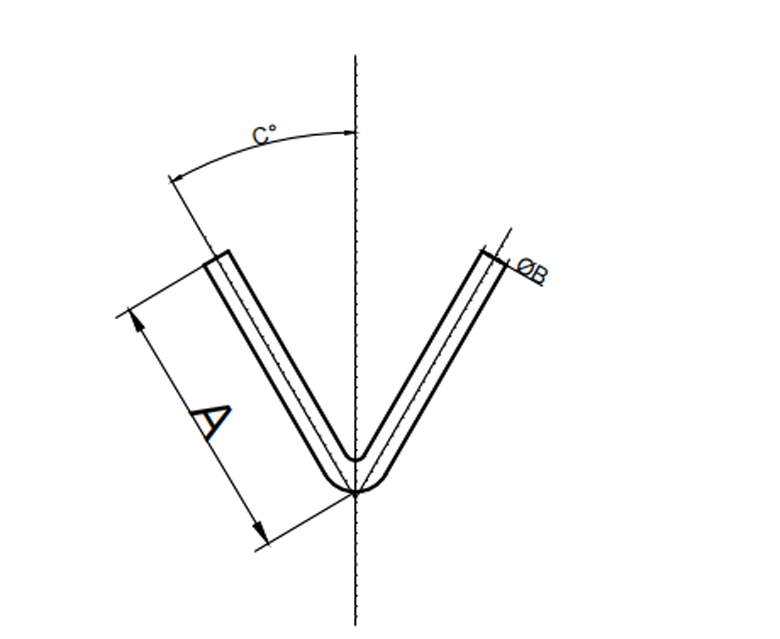

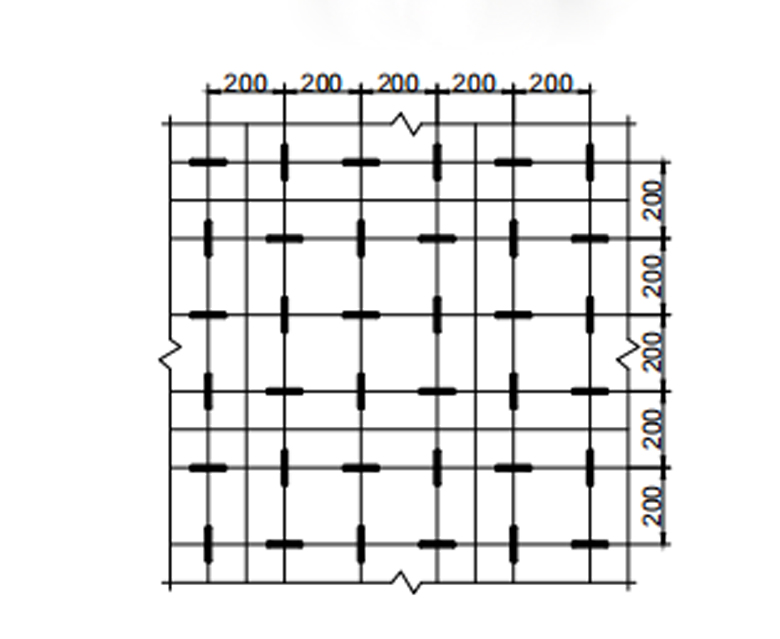

Common Sizes of V Refractory Anchoring Parts

| Code | A (mm) | B (mm) | C (mm) | Unit Weight (kg) |

|---|---|---|---|---|

| V-1 | 30 | 8 | 30 | 0.024 |

| V-2 | 40 | 8 | 30 | 0.031 |

| V-3 | 50 | 8 | 30 | 0.039 |

| V-4 | 60 | 8 | 30 | 0.047 |

| V-5 | 70 | 8 | 30 | 0.055 |

| V-6 | 80 | 8 | 30 | 0.063 |

| V-7 | 90 | 8 | 30 | 0.071 |

| V-8 | 100 | 8 | 30 | 0.078 |

| V-9 | 110 | 8 | 30 | 0.086 |

| V-10 | 120 | 8 | 30 | 0.094 |

Features of Anchoring Parts

- Increase Equipment Stability

Using ss refractory anchors with castable can increase the high-temperature equipment stability. Because anchor products can prevent the refractory castable shirk or crack under extreme temperatures.

- Increase Thermal Shock Resistance

Anchors have good thermal shock resistance. So installing castable anchor contributes to enhancing the thermal shock resistance of industrial high-temperature equipment. They also can resist mechanical shock.

- Decrease the Linings Dropping

These anchors help to fix the inner part. It greatly reduces the dropping of linings. In this situation, the slag will not affect the normal produce. Besides, the wavy anchors can increase the contact area of linings and keep the equipment stable.

- Good Chemical Resistance

Anchors can resist chemical erosion. Whether metal anchors or ceramic anchors both have stable chemical capacity. They will not react with the chemical gas or slag in the high-temperature equipment.

- Widely Usage

Ceramic anchors refractory are widely used in many high-temperature equipment that are constructed with castable. Due to the wide range of temperatures, they can suit different industrial equipment. Metal anchors are usually used in thin linings, and ceramic anchors are usually used in thick linings.

- Easy Installation

Compared with other refractory materials, Kerui refractory anchors are more easy to install. Because they have a small volume and light weight. In the construction process, that can save much time and labor. This can greatly reduce the costs of economy and time.

Usages of Refractory Anchors

Anchors are mainly used in integral linings, but they are also used in refractory brick linings. Using different anchors can help to resist mechanical shock, like Y anchor refractory, and V anchor refractory. Stainless steel anchors usually support or strengthen the thin linings, including the linings of chimneys, spray guns, DH and RH vacuum degassing devices, the outlet of rotary kilns, and so on.

Ceramic anchor products are used in more than 1200℃ in a long working time. They also can resist chemical erosion. Compared with metal anchors, ceramic fiber anchors’ contact area with refractory materials is large. So they can be used in thick linings. Anchor Y is a hot product.

Good Reviews from Kerui Customers

Reasons for Choosing Kerui

Kerui will reply to every inquiry of customers with an earnest attitude. If you need a one-stop service, we will recommend other refractory materials except for products. And we will recommend the most suitable materials to every customer. Finally, you can always believe the quality of Kerui refractory materials. We have intelligent control equipment to ensure the quality of every batch of products. View our LinkedIn to see more pictures.