Mullite refractory castable is mainly composed of mullite, whose components are Al2O3 and SiO2. The melting point of mullite is 1910℃ so that it has good refractoriness. This product presents the characteristics of low thermal expansion, good wear resistance, and good thermal resistance. Kerui provides this product to 1000+ partners as the leading manufacturer.

- Al2O3+SiO2: ≥70-90%;

- Maximum Service Temperature: ≥1600-1750℃;

- Linear Change Rate: ±0.6% (1100/1500℃*3h);

- Cold Bending Strength: 10-15Mpa (110℃*24h);

- Packaging: 25kg/bag;25kg/barrel;

- Delivery: 7-15 working days;

Technical Data of Mullite Refractory Castable

| Item | ML-17 | ML-80 | ML-90 | |

|---|---|---|---|---|

| Maximum service temperature,℃ | 1600 | 1600 | 1750 | |

| Al2O3+SiO₂,% | ≥70 | ≥80 | ≥90 | |

| B.D After Drying at 110℃,g/cm³ | 2.7 | 2.8 | 2.9 | |

| Cold Bending Strength,Mpa | 110℃*24h | 10 | 12 | 15 |

| Cold Compressive Strength,Mpa | 110℃*24h | 100 | 100 | 150 |

| Linear Change Rate After Burning PLC,% | 1100℃*3h | ±0.3 | ±0.3 | ±0.3 |

| 1500℃*3h | ±0.5 | ±0.5 | ±0.5 | |

| Construction Reference Water Consumption,% | 4.5-5 | 4.5-5 | 4.5-5 | |

Features of Mullite Castable

Low Thermal Expansion

Low thermal expansion means mullite castable has a low linear change rate. This refractory castable for sale is conducive to keeping the equipment stable. Meanwhile, it reduces the high-temperature damage to industrial equipment. So it can extend the life cycle of furnaces, and reduce the costs of repair. It is usually used for steam boiler and lining of furnaces.

Good Wear Resistance

Mullite castable has good chemical stability. It can sustain a stable state when it suffers erosion or shock. The cold compressive strength is 100MPa when it is used in 24 hours and 110℃. Good wear resistance helps the equipment undertake strong abrasion in high-temperature situations. It could used for the vulnerable parts.

Good Thermal Resistance

Mullite refractory castable can contact flame directly. It has good thermal resistance that can resist the thermal shock. Therefore, it can resist the high temperature and high pressure in service time. The low linear change rate also means it has good thermal resistance as a refractory material. It could used in tubular heating furnaces for the petrochemical industry or other industries.

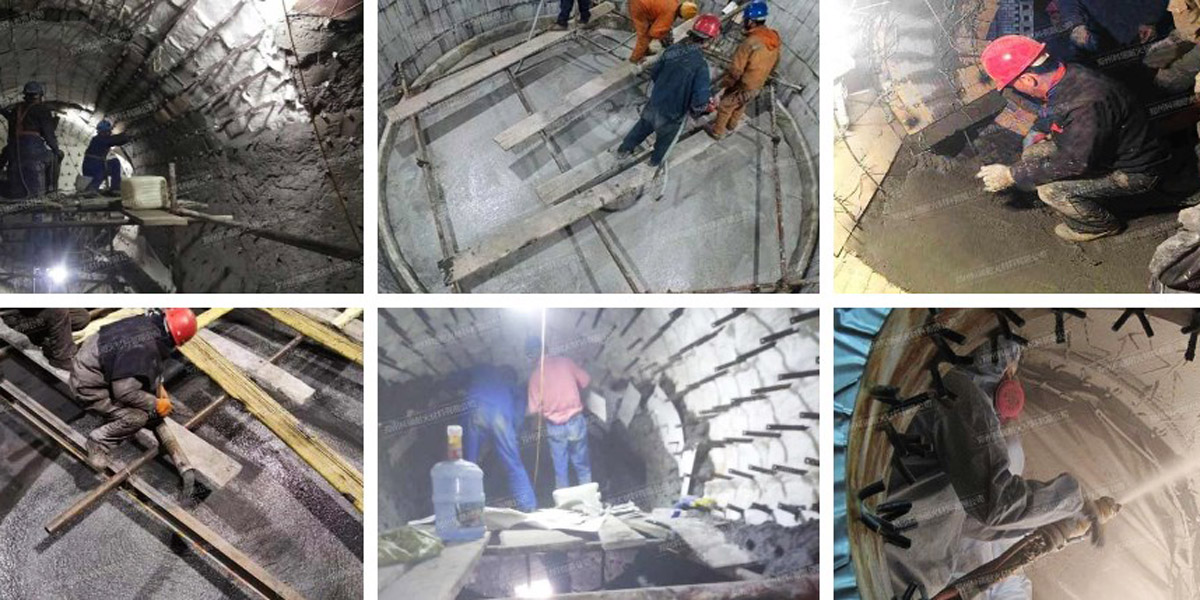

Applications of Mullite Based Castable

Mullite based castable is a kind of refractories and monolithics. This material can directly touch the flame as working linings. It is suitable for linings of observation doors, steam boilers, tubular heating furnaces for the petrochemical industry, other industrial furnace doors, and so on.

Strength and Hardness Improvement of Mullite Refractory Castable

Mullite-based castable improves the abilities by adding other raw materials.

- It could add corundum to enhance the compressive strength. It can be used in medium and large cement kilns’ mouths, coal-injection ducts, head covers, and so on.

- It could improve the wear resistance by adding corundum and steel fiber. It can used in cement kilns, boilers of power plants, and furnace doors of industrial furnaces.

Kerui will provide a suitable price for mullite castable to every customer. Our factory is in Xinmi and has abundant high-quality raw materials. And we have professional production equipment and patented technology to ensure high quality and high volume production. Therefore, you do not need to worry about the quality of our mullite refractory castable. As a mullite castable manufacturer, we have a stable production line/large production capacity and a professional service team to ensure every order succeeds smoothly. We hope to build a long-term cooperation with every customer. View more cases on Kerui Linkedin.