Mullite refractory brick is primarily composed of mullite as the main crystalline phase in high-alumina refractory materials. Due to their high alumina content, they exhibit superior performance and are widely used. Kerui Refractory can customize special mullite bricks based on specific application scenarios.

- Al2O3: ≥70-75%;

- Fe2O3: 0.4%;

- Refractoriness: 1680ºC;

- Apparent Porosity: 26-28%;

- Cold Crushing Strength: 25MPa;

- Size: 230*114*65mm (standard)/And other sizes;

- Delivery: 15-30 working days;

Specification Data of Kerui Mullite Bricks

Kerui Refractory mainly offers two types of refractory bricks. The main difference between these two types (MLS-75 and MLS-70) lies in the varying Al2O3 content. Customers can choose the appropriate product based on the performance of different types.

| Item | MLS-75 | MLS-70 | |

|---|---|---|---|

| Al2O3, % | ≥ | 75 | 70 |

| SiO2, % | ≤ | 23 | 25 |

| Fe2O3, % | ≤ | 0.4 | 0.4 |

| Bulk Density, g/cm3 | ≥ | 2.7 | 2.6 |

| Apparent Porosity, % | ≤ | 18 | 18 |

| Cold Crushing Strength, MPa | ≥ | 100 | 100 |

| 0.2MPa Refractoriness Under Load, ℃ | ≥ | 1680 | 1680 |

Types of Mullite Refractory Brick

| Brick Type | Primary Process | Key Characteristics & Advantages | Typical Applications |

|---|---|---|---|

| Sintered Mullite Bricks | High-temperature firing | Balanced performance; Excellent structural strength at high temps; Good chemical resistance, and cost-effective. |

Linings for various industrial kilns (hot blast stoves, ceramic kilns, lime kilns). |

| Fused Mullite Bricks | Electric arc melting | Higher purity, extreme density; Superior erosion & penetration resistance; Excellent thermal shock resistance. |

Critical areas under severe erosion (glass furnaces, carbon black reactors, gasifiers). |

| Zirconium Mullite (AZS) Bricks | Typically fused | Unmatched corrosion resistance against molten glass; Low pollution to glass melt at high temperatures. |

Core zones in direct contact with glass melt (glass furnace sidewalls, throat, weir). |

| Sintered Zirconium Mullite Bricks | Sintering | Better thermal shock & erosion resistance than standard sintered mullite; Lower cost than fused AZS. |

High-demand kiln furniture (shelves, posts); High-temp zones of ceramic kilns; Superstructure of glass furnaces. |

| Corundum Mullite Bricks | Sintering | Higher refractoriness & load softening temperature; Better high-temp strength & abrasion resistance. |

Applications requiring extreme strength & wear resistance (petrochemical crackers, carbon black reactors, high-temp tunnel kilns). |

| Mullite Insulation Bricks | Firing with pore formers | Lightweight, low thermal conductivity; Excellent thermal insulation & energy saving; Low heat capacity. |

Insulation/backing linings in industrial furnaces; Working linings in mid-to-low temp furnaces for heat loss reduction. |

Introduction of Mullite Refractory Brick

Kerui mullite bricks are mainly made from High-quality mullite as raw material. Its main components are Al2O3 and silica. Therefore, it has strong acid resistance and lower alkali resistance. Kerui Refractory provides a variety of refractory brick models. It can be used in various high-temperature scenarios.

Classification of Kerui Mullite Bricks

Kerui Refractory provides two categories of mullite bricks based on production processes, mainly including sintered mullite bricks and fused mullite bricks.

Sintered Mullite Brick

- Sintered mullite brick production process: High-quality raw materials such as mullite are mixed and then entered into an automated press for molding. The molded refractory block is then sent to a tunnel kiln for drying and sintering.

- Features: The sintered mullite bricks have good thermal shock resistance and mechanical stability.

Fused Cast Mullite Brick

- Fused mullite brick production process: High-quality materials such as mullite are mixed and melted in an electric furnace. The melted raw materials are then molded in a mold. The production process is environmentally friendly.

- Characteristics: The refractory bricks fused through electricity have superior high-temperature resistance and corrosion resistance. It can help improve the durability of equipment.

In addition, we also provide heavy mullite bricks, lightweight mullite bricks, low creep mullite bricks, anti-stripping mullite bricks, high purity mullite bricks. Please contact us for detailed parameters and prices.

Good Mullite Bricks Properties

Strong Anti-creep Ability

Mullite bricks have a high refractoriness, reaching up to 1790 degrees Celsius. Mullite bricks with high anti-creep properties can maintain their structural integrity and shape when exposed to high temperatures for a long time. Size stability plays an important role in high-temperature industries.

Strong Chemical Stability

Mullite bricks can resist chemical reactions or degradation when exposed to various chemicals or harsh environments. They are known for their corrosion resistance, erosion resistance, and chemical attack resistance. They are suitable for alkaline high-temperature industries and also exhibit some resistance to low-acid environments.

Excellent Thermo-mechanical Stability

The softening temperature of mullite is 1600-1700 degrees Celsius. It maintains its structural integrity and mechanical performance under high temperatures and thermal stress. Additionally, it exhibits minimal expansion or contraction at high temperatures, making it an ideal choice for applications requiring thermal stability and mechanical strength.

High Thermal Conductivity

This characteristic allows high alumina mullite bricks to quickly transfer heat from one area to another, making them suitable for applications where heat transfer is crucial, such as furnaces or kilns. They also have good insulation properties, making them suitable for the high-temperature electrical insulation industry.

Wide Uses of Mullite Bricks

Cement Industry

In the cement industry, mullite bricks are used in cement kilns, rotary kilns, and other equipment to withstand the high temperatures, vibrations, abrasion, and corrosion in cement production, making them widely used in the industry.

Glass Industry

In the glass industry, mullite bricks are used in glass furnaces and regenerators. They can withstand extremely high temperatures in glass melting furnaces and resist glass corrosion, thereby extending the equipment’s lifespan.

Ceramics

In the ceramic industry, mullite bricks are used in ceramic kilns, sintering kilns, and regenerators to improve the durability and stability of these devices, ensuring the quality and production efficiency of ceramic products.

Steel Smelting Industry

The application of mullite bricks in the steel smelting industry is suitable for equipment such as hot blast stoves, blast furnaces, and annealing furnaces in the steel industry, helping to resist chemical erosion in high-temperature environments. At the same time, it can maintain stable performance at high temperatures.

Electrical Industry

In the electrical industry, mullite and magnesium bricks are used in high-temperature electric furnaces, arc furnaces, and other high-temperature equipment to withstand the high-temperature environments and chemical corrosion in electrical equipment, also playing a role in insulation.

Energy and Environmental Protection Industry

In the energy and environmental protection industry, they are used in cracking equipment, refining equipment, incinerators, and other high-temperature devices to improve the efficiency of these environmental protection devices and reduce energy consumption.

Low Factory Kerui Mullite Brick Prices

Kerui Refractory offers two methods to calculate the price based on the weight (tonnage) or the number of bricks. The more quantity purchased, the more favorable the price. Customers can provide details of their furnace to receive recommendations tailored to their specific needs, including the type of refractory bricks, quantity, placement, and other factors. This personalized approach ensures customers receive accurate quantities and the best possible pricing. For current pricing details, I recommend reaching out directly to Kerui Refractory for a quote based on your specific requirements.

1000+ Partners Choose Kerui Refractory

Kerui Refractory offers a diverse range of mullite refractory bricks and other refractory materials, catering to the varied refractory requirements of its customers. With over 1000 satisfied partners worldwide, Kerui Refractory stands out as a trusted provider of not only high-quality refractory products but also exceptional service.

Partners have placed their trust in Kerui Refractory. They are from various countries, including Russia, Indonesia, South Korea, Saudi Arabia, etc.

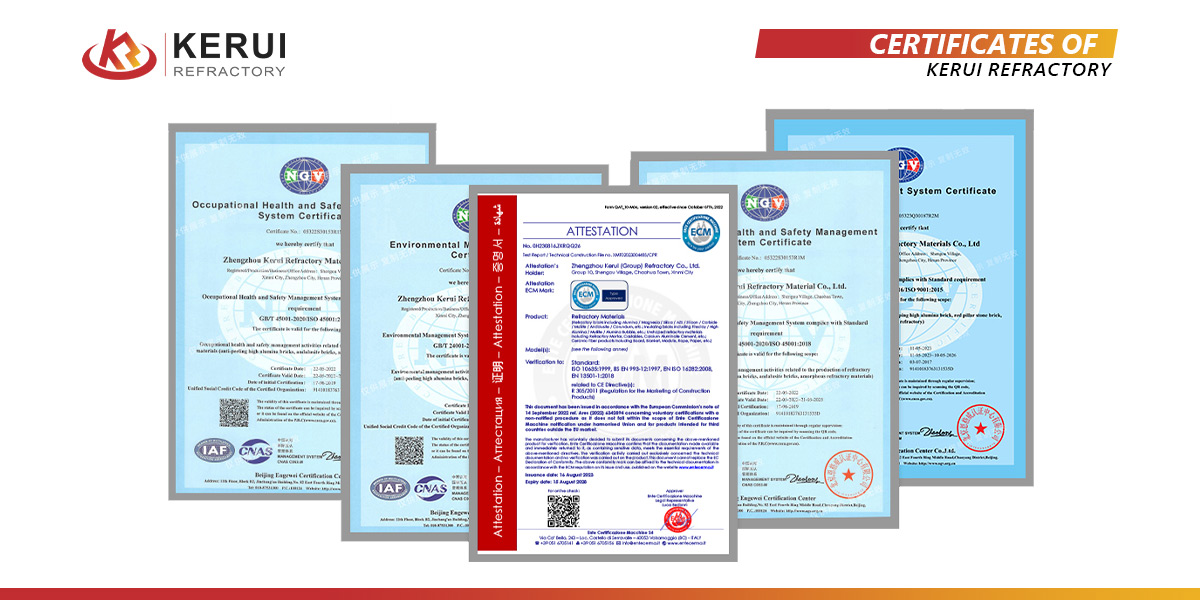

Kerui Refractory is The Top Leading Mullite Brick Manufacturer

Raw Materials

Kerui Refractory selects high-quality mullite sand and other refractory raw materials from premium sources. This allows us to control the performance, durability, and stability of mullite bricks from the source, while also improving production efficiency.

Production

As the primary factory, Kerui Refractory has two 168-meter automated production tunnel kilns, 20 units of 400-1000 ton presses, and a fully intelligent automatic control system. These systems ensure high-quality production and high-speed efficiency of mullite bricks.

Inspection

After the factory completes the production of mullite bricks, the quality inspection team conducts sampling tests on the bricks. Testing includes hot softening temperature tests, flexural strength tests, density tests, and more. We ensure the delivery of the best quality and customer satisfaction with our mullite bricks.

Research and Development

Kerui Refractory has a research and development team with years of experience. They continuously improve existing mullite bricks and other refractory products, as well as develop new products, leading the industry’s development.

Service

Refractory suppliers provide one-stop services from customized refractory materials to project construction. Customers can send us their specific requirements, and we can help solve the rest for you. We ensure worry-free service.

After-sales Service

We offer technical support, maintenance, and other after-sales consultation services. We provide continuous support and service to customers during the use of mullite bricks.

Get Mullite Brick Solution from Kerui Refractory Now!

As a magnesia brick manufacturer, Kerui Refractory actively provides high-quality, durable Kerui brick products. Through careful selection of raw materials, advanced production techniques, and strict quality control, we ensure that each brick meets the highest standards. Our team has extensive experience and professional knowledge, capable of providing customized mullite brick solutions to meet various project requirements. If you would like to see more pictures, view Pinterest. Choose us as your reliable partner and let’s work together to build solid and durable construction projects.