- MgO: ≥45-65%;

- Cr2O3: ≥8-16%;

- Refractoriness Underload: 1530-1650ºC;

- Cold Crushing Strength: 25-35MPa;

- Size: 230*114*65mm (standard)/And other sizes;;

Specifications of Magnesite Chrome Bricks

| Item/Grade | MGe-16A | MGe-16B | MGe-12A | MGe-12B | MGe-8A | MGe-8B | |

|---|---|---|---|---|---|---|---|

| MgO, % | ≥ | 50 | 45 | 60 | 55 | 65 | 60 |

| Cr2O3, % | ≥ | 16 | 16 | 12 | 12 | 8 | 8 |

| Apparent Porosity, % | ≤ | 19 | 22 | 19 | 21 | 19 | 21 |

| Cold Crushing Strength, MPa | ≥ | 35 | 25 | 35 | 30 | 35 | 30 |

| 0.2MPa Refractoriness Under Load, ℃ | ≥ | 1650 | 1550 | 1650 | 1550 | 1650 | 1530 |

Types of Magnesite Chrome Bricks for Your Options

Kerui Refractory offers the following types of magnesia chrome bricks, including ordinary sintered magnesia carbon bricks, directly combined magnesia chrome bricks, fused magnesia chrome bricks, and unfired magnesia chrome bricks. The above parameters are for ordinary sintered magnesia chrome bricks. If you need parameters for other types, please contact us.

| Type | Key Performance Indicators |

|---|---|

| Chemically Bonded Unfired Magnesia Chrome Brick (DMGe8/DMGe12/DMGe16) |

Simple production process; Low cost; Suitable for medium to low temperature environments |

| Direct Bonded Magnesia Chrome Brick (SRMGe16/SRMGe18/SRMGe20/SRMGe22/SRMGe26/MGe8/MGe12/MGe16) |

High temperature strength ≥15MPa; Excellent slag erosion resistance; Thermal shock stability ≥10 cycles (1100°C water quench). Commonly used for steel smelting and non-ferrous metal smelting. |

| Semi-Rebonded Magnesia Chrome Brick | Thermal shock resistance ≥15 cycles (1100°C water quench); Balanced high-temperature performance; Partially uses fused raw materials. |

| Fused Rebonded Magnesia Chrome Brick (RMGe12/RMG14) |

Apparent porosity ≤15%; High temperature flexural strength ≥20MPa (1400°C); Uses fused raw materials as base. |

| Fused Cast Magnesia Chrome Brick | Dense structure; Excellent erosion resistance; Bulk density ≥3.2 g/cm³. Commonly used for glass kilns and cement kilns. |

| Silicate Bonded Magnesia Chrome Brick | Low cost; Mature production process; Suitable for general industrial kilns. |

Introduction to Magnesia Chrome Bricks

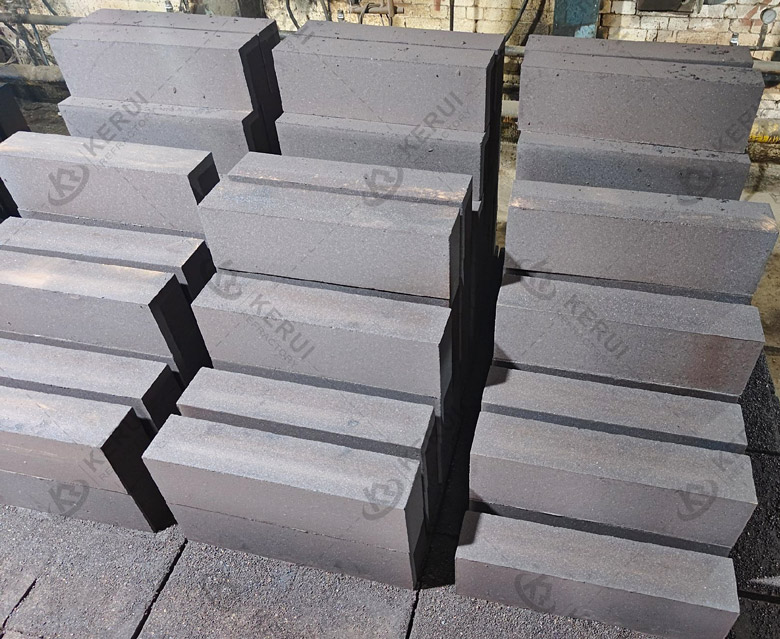

Magnesia chrome bricks are mainly produced through sintering and fused. Its main components are magnesium oxide and Cr2O3. Kerui uses high-quality, carefully selected raw materials for its bricks. This ensures that the quality of the finished product is guaranteed.

- Magnesium oxide comes from high-quality magnesia. It serves as the primary component. It has high temperature resistance, corrosion resistance, and good thermal shock stability.

- Cr2O3 comes from chromium ore. It serves as the second major component. It can enhance the performance of magnesia chrome bricks, such as refractoriness, corrosion resistance, and thermal shock stability.

The Characteristics of Magnesium Chromium Bricks

High Temperature Resistance

Withstands extreme temperatures up to 1700°C.

High refractoriness under load (1500-1650°C softening range).

Strong Resistance to Alkali Slag Erosion

Excellent chemical stability in alkaline environments.

Forms protective chromium oxide layer against corrosive slag.

Strong Resistance to Spalling

Maintains structural integrity under thermal cycling.

Resists peeling and cracking from mechanical stress.

Environmental Friendliness

Eco-friendly natural raw materials & production process.

Fully recyclable to reduce resource consumption.

Magnesium Chromium Brick Shapes for Specific Kiln Zones

| Application Area & Requirement | Functional Need | Corresponding Brick Type |

|---|---|---|

| Straight Walls, Flat Floors (Standard Structures) |

Simple laying, structural stability | Standard Brick / Regular Shape Brick |

| Arches, Domes (Curved Structures) |

To form a stable self-locking arch | Wedge Brick |

| Furnace Shells (e.g., Rotary Kilns) |

To assemble into a perfect ring | Arch Brick / Key Brick |

| Wall Corners, Ends | To create smooth transitions, avoid straight joints | Skew Brick / Arch Support Brick |

| Burner Blocks, Inspection Holes, Thermocouple Ports | To form a regular and robust opening | Special Shape Brick (Burner Block) |

Chrome Magnesitea Bricks Are Used for Various Industries

Steel Metallurgy Industry

The steel metallurgy industry uses magnesia chrome refractory bricks to construct blast furnaces, electric furnaces, refining furnaces, oxygen converters, high-temperature tunnel kilns, rotary kilns, heating furnaces, and so on.

Non-ferrous Metal Industry

The non-ferrous metal industry uses them in flash smelting furnaces, smelting furnaces, and other high-temperature equipment. Operators typically apply these bricks in the smelting of copper, aluminum, nickel, zinc, and other metals.

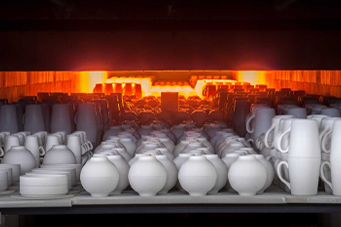

Glass Industry

The glass industry uses magnesia chrome bricks in glass melting furnaces, glass regenerators, and other high-temperature applications. The bricks withstands high temperatures, corrosion, thermal cycling, and other conditions during the glass manufacturing process.

Other Industries

Additionally, other industries such as cement, ceramics, and petrochemicals use magnesia chrome bricks in their processes. They provide reliable and durable refractory solutions for these high-temperature industries for a long-term time.

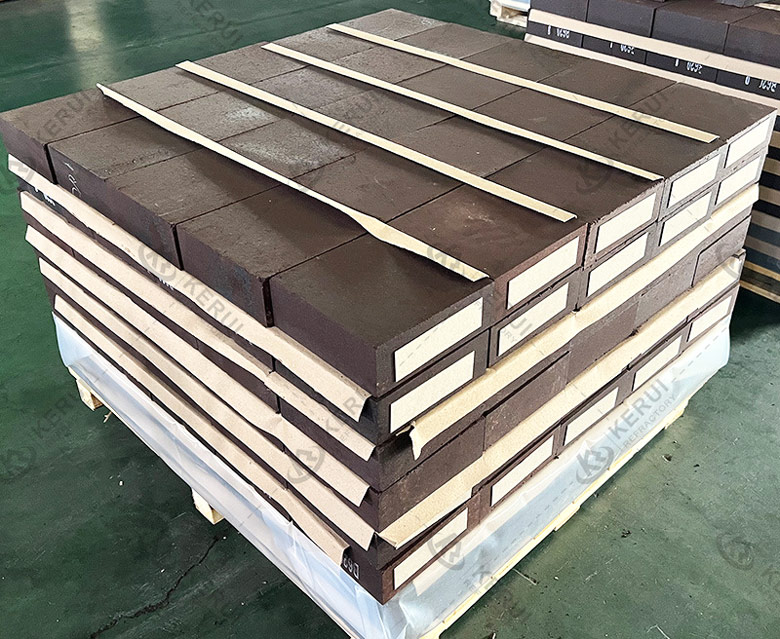

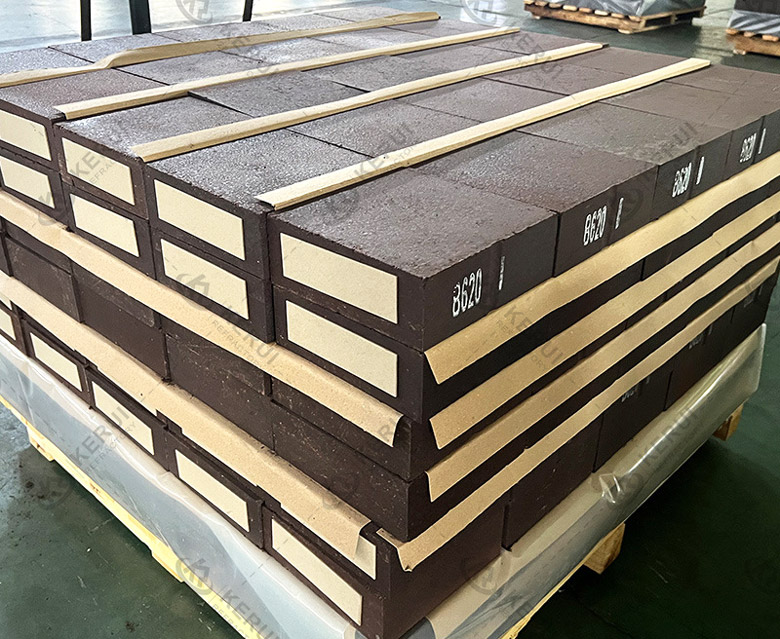

A Manufacturer and Solution Expert for Magnesia Chrome Bricks – Kerui

- As a manufacturer, Kerui Refractory produces up to 250,000 tons annually. And we rank among the top three in the refractory industry in China.

- The company possesses strong factory capabilities and corporate strength. We have over 20 patented technologies, 20+ corporate honors, ISO, and other international certificates.

- The factory operates with full digital control. This system ensures precision in every step to guarantee the high quality of magnesia chrome bricks.

- As solution experts, our international business managers provide personalized consulting services.

- We offer customized magnesia chrome bricks based on customer-provided drawings, including shapes, colors, compositions, and sizes.

- Standard bricks are available for immediate delivery. And we have extensive experience in customizing magnesia chrome bricks with short production cycles and fast delivery times.

- Additionally, we can provide kiln materials solutions and construction technical guidance tailored to the specific needs of our customers.

Kerui Magnesia Chrome Brick is Your Solution!

Kerui produces magnesia chrome bricks through a fully digitalized production system and implements a rigorous quality inspection process to ensure each brick meets high product quality standards. As the original factory, Kerui Refractory offers factory-direct pricing. What’s more, we provide customized refractory material solutions tailored to the specific requirements of your kilns. Drawing on over 20 years of experience and the expertise of 200+ professionals, we help you find the right solutions for your needs. See some videos on YouTube.