Magnesia alumina spinel brick is a synthetic material. It consists of alumina oxide and magnesia oxide. Magnesia alumina bricks produced by Kerui have been exported to 50+ countries. Kerui is devoted to providing solutions for refractory materials and bricks.

- MgO: ≥80%;

- Al2O3: ≥10%;

- Bulk density: ≥2.9g/cm3;

- Apparent Porosity: ≤17%;

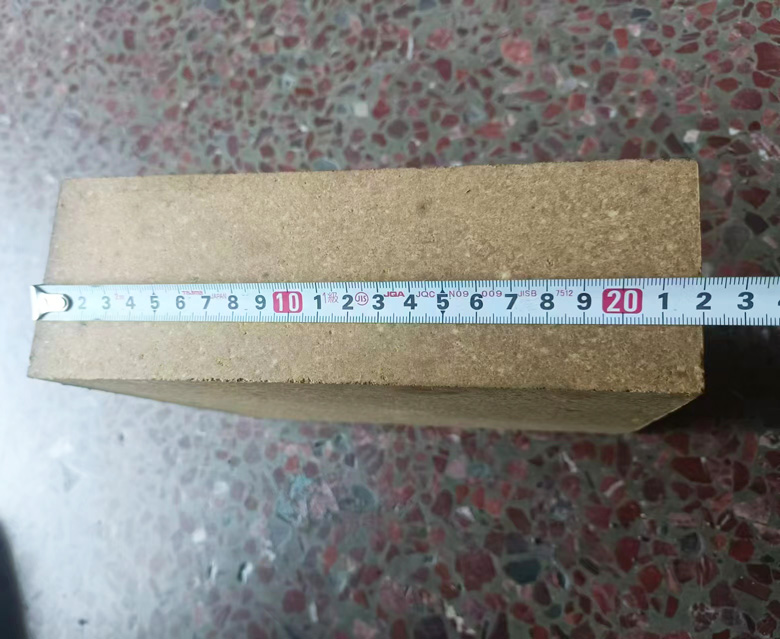

- Standard size: 230*114*65mm (standard)/And other sizes;

Technical Data of Magnesia Spinel Bricks

| Item | Index | |

|---|---|---|

| MgO, % | ≥ | 80 |

| Al2O3, % | ≥ | 10 |

| Apparent Porosity, % | ≤ | 17 |

| Bulk Density, g/cm³ | ≥ | 2.9 |

| Cold Crushing Strength, MPa | ≥ | 50 |

| High-temperature Bending Strength (1350℃*0.5h), MPa | ≥ | 3.5 |

| Thermal Shock Resistances (1100℃, Water Cooling), Cycle | ≥ | 12 |

Sizes of Magnesia Alumina Spinel Brick

The standard size is 230*114*65mm. We also have other sizes of bricks can provide to customers including knife bricks, universal arc bricks, chequer bricks, etc. Moreover, if you need to customize different sizes of bricks, please give the specifications.

Characteristics of Spinel Bricks

- Strong Alkaline Erosion Resistance: Magnesia alumina spinel brick is an alkaline material. It can resist alkaline erosion in high-temperature situations. So it is usually used for the linings of industrial equipment that have alkaline substances or solutions production.

- Good Resistance to Peeling: Magnesia spinel bricks have higher refractoriness than magnesia bricks. This brick can undertake more than 50MPa. So it can resist high-temperature and high-pressure environments. It is used for the linings of kilns or vulnerable parts.

- Great Thermal Stability: Magnesia alumina spinel bricks have a stable structure. The under load temperature can be up to 1600℃. They can resist extreme thermal shock that will not crack or damage. So they can sustain a steady state of high-temperature equipment.

- Low Thermal Conductivity: The low thermal conductivity contributes to having a good insulation ability. Magnesia alumina spinel brick can effectively improve the energy utilized that reduce heat transfer. So it can be used for linings of furnaces.

Applications of Magnesia Alumina Spinel Bricks

Magnesia alumina spinel refractory brick can replace mag chrome brick because it will not produce poisonous substances. It can be used for the linings of rotary kilns, the top of electronic furnaces, ladles lining, steel storage chamber in open hearth furnaces, and checker bricks in glass furnace heating chambers.

Strict Production Process

Kerui has an automatic batching system to control the raw materials ratio. We have a roller mill uniform mixing raw materials to ensure the performance of magnesia spinel brick. Besides, we have a high-efficiency production line to guarantee the delivery time.

Service Strength of Kerui

Kerui can meet the ends of customized service for customers because we have 10 years of customized experience. We can design suitable plans for customers. If you need special sizes of bricks, you can offer specific specifications to our technicians. Moreover, we have senior engineers and technical consultants who can recommend optimal solutions to customers. Follow Kerui Pinterest to see more pictures about Kerui factory.