In September 2025, a batch of JM26 mullite insulation bricks from Kerui Refractory was shipped to Tanzania. These bricks will be used to insulate thermal equipment in local industrial kilns. Customers are very excited about the results of our products.

Product Features and Technical Specifications Purchased by a Tanzanian Customer

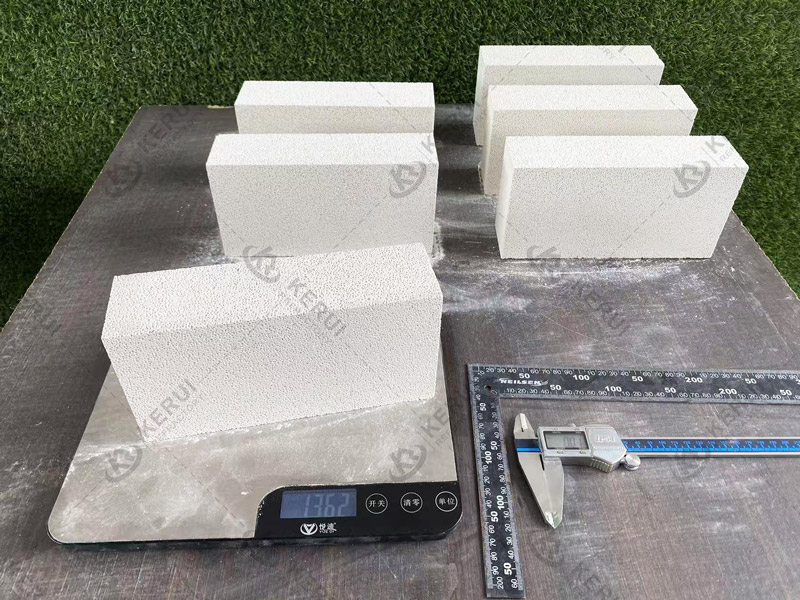

Kerui JM26 mullite insulation bricks are made from high-quality mullite raw materials using advanced production processes. Technical specifications include:

- Maximum operating temperature: 1400°C;

- Volume density: 0.7-1.0 g/cm³;

- Compressive strength at room temperature: ≥2-3.2 MPa;

- Thermal conductivity (350°C): 0.21-0.32 W/(m·K);

- Reburning line variation (1300°C x 12h): ±0.5%;

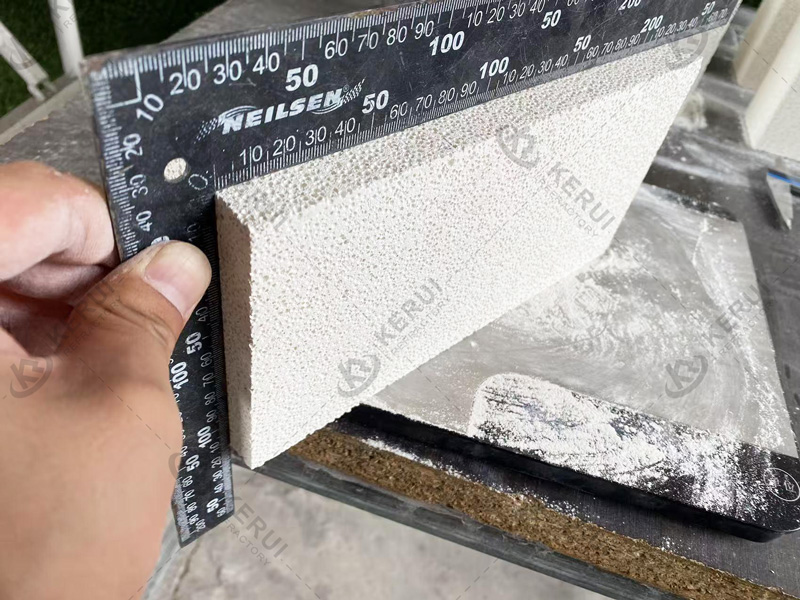

These technical specifications ensure product reliability and durability in industrial applications. The JM26 mullite insulation bricks feature a uniform microstructure and a well-balanced pore distribution, effectively reducing heat loss while ensuring sufficient mechanical strength.

Industrial Applications of JM26 Insulating Bricks

JM26 mullite insulation bricks are primarily used in the following applications in the Tanzanian market:

- Heating furnaces and heat treatment furnaces in the steel industry;

- Rotary kilns and preheaters in the cement industry;

- Tunnel kilns and shuttle kilns in the ceramics industry;

- Melting furnaces and annealing lehrs in the glass industry;

- Heat treatment equipment in the chemical industry.

These industrial equipment place stringent demands on refractory materials, requiring them to possess excellent thermal insulation, stable high-temperature volume stability, and superior thermal shock resistance.

Kerui Refractory’s Customization Capabilities

Kerui Refractory offers customized product solutions tailored to specific customer needs. This includes:

- Designing custom sizes and specifications based on the customer’s kiln structure;

- Adjusting product formulas to suit specific process conditions;

- Providing professional technical consultation and installation guidance;

- Assisting customers with optimized kiln insulation design.

Our technical team boasts extensive practical experience and can provide comprehensive technical support, from product selection to installation. Kerui has also established a comprehensive product testing system to ensure that every batch of products meets quality standards.

Logistics and Service Guarantee

To ensure timely and intact product delivery to Tanzanian customers, Kerui has established a professional logistics management system. Products are packaged in moisture-proof and shock-resistant packaging to ensure they remain intact during long-distance transportation. The company maintains long-term partnerships with several international logistics companies and can arrange optimal transportation solutions tailored to customer needs.

In terms of after-sales service, Kerui provides:

- Detailed product instructions;

- Timely technical consulting and support;

- Necessary on-site technical services;

- Regular customer visits.