Insulation refractory bricks (IFB) are lightweight refractory bricks that can withstand temperatures up to 1800°C. It’s commonly used in industrial furnaces due to its low thermal conductivity, enhancing energy efficiency.

- Bulk Density: 0.55-1.7g/cm³;

- Thermal Conductivity: 0.17-1.5W/m·k;

- Cold Crushing Strength: 1.2-12MPa;

- Size: 230*114*65mm (standard)/other sizes;

- Delivery: 15-30 working days;

- Price: Low EX-factory price;

Types Of Kerui Insulating Refractory Bricks

Kerui primarily offers 5 types of insulation bricks, including clay insulation bricks, silica insulation bricks, high-alumina insulation bricks, mullite insulation refractory bricks, and alumina hollow ball bricks.

Beyond these soft insulation bricks, we also provide complementary products such as steel plates, ceramic fiber products, calcium silicate cement, and refractory castables.

Clay Insulation Refractory Brick

- Grade: NG135-1.3, NG135-1.2, NG130-1.0, NG125-0.8, NG120-0.6;

- Al2O3: ≥30-48%;

- Bulk Density: ≥0.6-1.3g/cm³;

- Cold Crushing Strength: ≤1.3-5MPa;

- Thermal Conductivity: 0.25-0.55W/m·k;

High Alumina Lightweight Refractory Brick

- Grade: LG140-1.2, LG140-1.0, LG140-0.8L;

- Al2O3: ≥48%;

- Bulk Density: ≤0.8-1.2 g/cm³;

- Cold Crushing Strength: ≥2.5-4.5 MPa;

- Thermal Conductivity: ≤0.35-0.55W/m·k;

Mullite Insulation Refractory Brick

- Grade: JM-23 (KR-23), JM-26 (KR-26), JM-28 (KR-28), JM-30 (KR-30);

- Al2O3: ≥38-73%;

- Bulk Density: ≤0.55-1.1 g/cm³;

- Cold Crushing Strength: 0.17-0.43 MPa;

- Thermal Conductivity: 0.17-1.5W/m·k;

Alumina Bubble Insulation Refractory Brick

- Grade: 85, 90, 99;

- Al2O3: ≥90-99%;

- Bulk Density: ≤1.0-1.2 g/cm³;

- Cold Crushing Strength: ≥2.0-5.0 MPa;

- Thermal Conductivity: ≤0.8-1.5W/m·k;

Silica Insulation Refractory Brick

- Grade: GGR-1.00, GGR-1.10, GGR-1.15, GGR-1.20;

- SiO2: ≥91%;

- Bulk Density: ≤1.4-1.7 g/cm³;

- Cold Crushing Strength: ≥9-12 MPa;

- Thermal Conductivity: 0.55-0.70W/m·k;

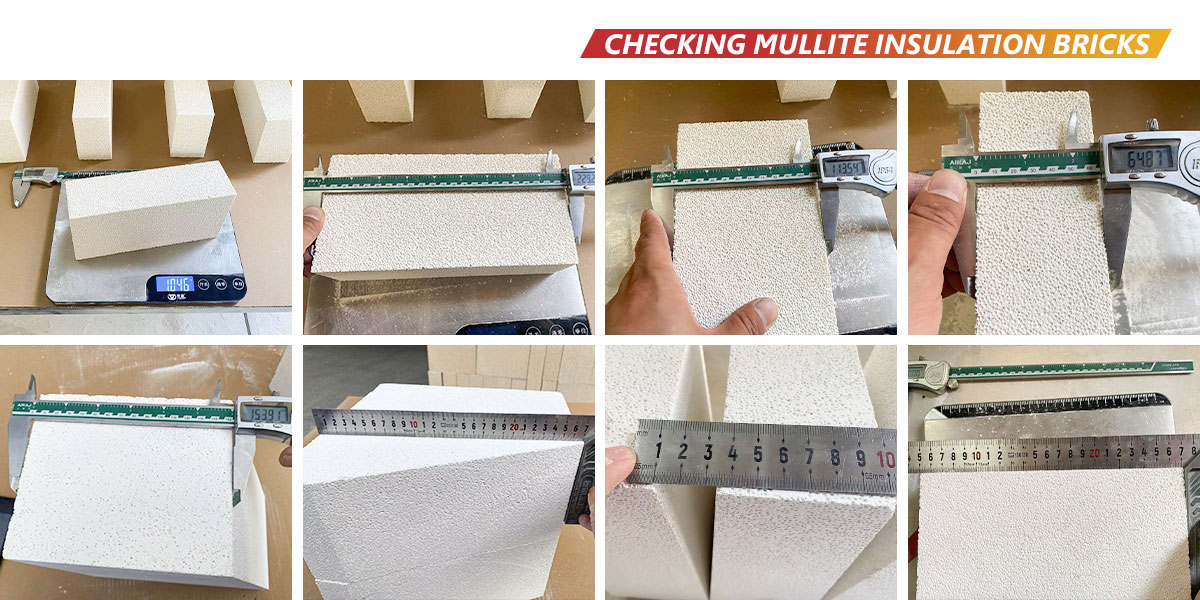

Strict Quality Control of Kerui Insulating Refractory Bricks

- Good Raw Materials: Our insulating refractory bricks are manufactured using only the finest, rigorously tested raw materials.

- Accurate Production System: The entire production process, from batching to firing in our 2*168-meter tunnel kiln, is digitally controlled for precision and consistency.

- Full Quality Checking: Comprehensive quality checks include dimensional inspections, compositional analysis, and various physical tests, ensuring that our products meet the highest standards.

- International Certificates: To further solidify our commitment to quality, Kerui holds a range of international certifications and patents related to refractory insulation bricks.

- Comprehensive Packing and Shipping: Our dedicated packaging and shipping team in fthe actory employs rigorous protocols to guarantee that our products arrive at their destination in pristine condition.

Features of Kerui Refractory Insulation Bricks

- Low thermal conductivity and good thermal insulation;

- Low heat storage;

- Lightweight;

- Good wear resistance;

- Good corrosion resistance;

- High apparent porosity;

- High purity, consistent raw materials;

- High hot compressive strength;

- Tight dimensional tolerances;

- Large bricks or slabs and special shapes available;

- Purpose-designed packaging protects bricks in transit and facilitates on-site handling.

Uses of Kerui Soft Refractory Brick

Kerui refractory insulation bricks serve as essential inner linings for a wide range of industrial furnaces, including tunnel kilns, shuttle kilns, metallurgical furnaces, heat treatment furnaces, glass melting furnaces, ceramic sintering kilns, anode baking furnaces, blast furnaces, converters, electric arc furnaces, copper smelting furnaces, aluminum electrolytic cells, zinc smelting furnaces, and incinerators.

Additionally, they are employed in various industrial equipment such as high-temperature reactors and heat exchangers. Given this extensive range of applications, Kerui is well-equipped to provide tailored refractory solutions for a multitude of industries.

Kerui Refractory is Your First Choice in China

- OEM Capabilities: Kerui operates a 50,000 square meter manufacturing facility equipped with fully automated production lines.

- Competitive Pricing: As a direct manufacturer, Kerui offers our customers highly competitive factory-direct pricing.

- Comprehensive Services: Our services encompass consulting, customization, technical guidance, and on-site installation.

- Customized Solutions: We provide tailored solutions for a variety of industrial furnaces and offer a comprehensive range of refractory products to meet your specific needs.

- EPC Services: Kerui offers end-to-end EPC services, including design, procurement, construction, and commissioning, to streamline your project and reduce overall costs. View Kerui LinkedIn to see more services we provide for customers.