Corundum Brick

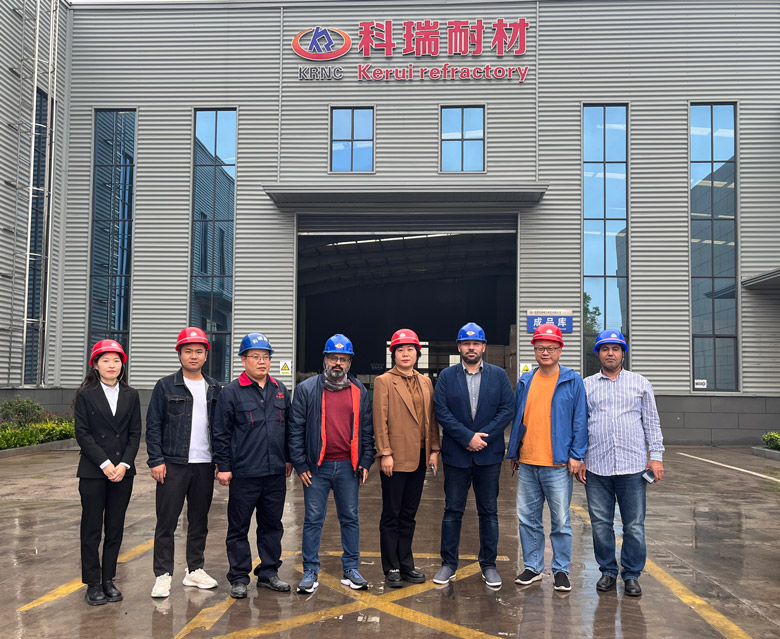

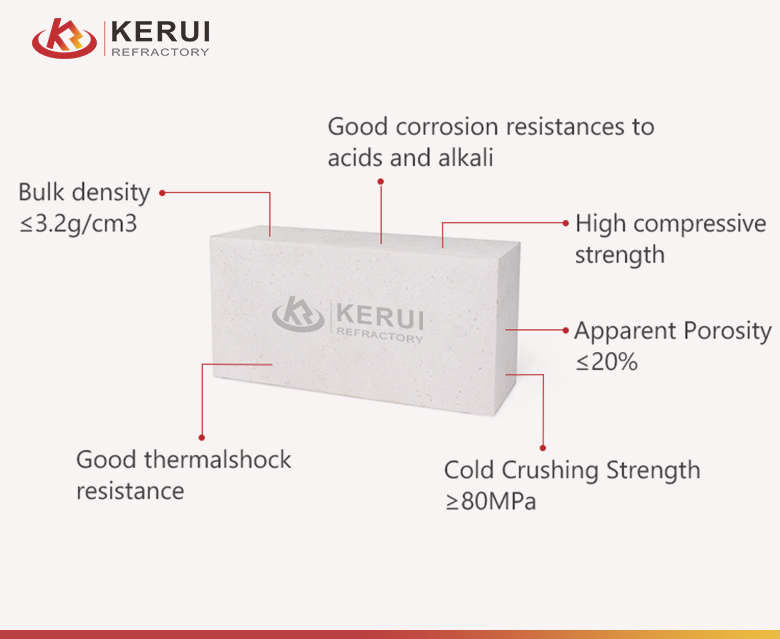

Corundum bricks are high-grade refractory materials. They resist corrosion from acidic or alkaline slag, metal, and molten glass. As a manufacturer, Kerui has provided both standard and customized products to over 50 clients worldwide, earning consistent praise from our customers.

- Free Sample:

- Available

- Document:

- Certificates Supporting

- Performance Test:

- Support

- Shipment:

- 7-35 working days globally

Different Types of Kerui Corundum Bricks for Sale

As a factory-owned manufacturer, Kerui offers a wide variety of corundum bricks. These bricks can meet the needs of both conventional and extreme environments across most industries. For recommendations, please send us your application and detailed requirements.

| Classification | Typical Type | Core Characteristics | Primary Application Scenarios |

|---|---|---|---|

| By Mineral Composition | Chrome Corundum Brick | Excellent resistance to acidic slag erosion | Glass furnace sidewalls, throat areas |

| Zirconia Corundum Brick (AZS) | Superior resistance to molten glass corrosion | Glass furnace tank walls, doghouse areas | |

| Mullite Bonded Corundum Brick | Good thermal shock resistance, high creep resistance | Hot blast stoves, ceramic kilns, gasifiers | |

| By Al₂O₃ Content | 95% Alumina Corundum Brick | Well-balanced overall performance | Cement kiln transition zones, large ladles |

| 99% High-Purity Corundum Brick | Very high refractoriness, high strength | Carbon black reactors, gas generators | |

| By Manufacturing Process | Sintered Corundum Brick | Uniform structure, versatile | General purpose choice for various industrial furnaces |

| Fused Corundum Brick | Extremely dense, excellent corrosion resistance | Most severe service conditions |

Parameters of Kerui Corundum Brick

| Item | GYZ-99 | GYZ-90 | GYZ-80 | |

|---|---|---|---|---|

| Al2O3, % | ≥ | 99 | 90 | 80 |

| SiO2, % | ≤ | 0.2 | 8 | 18 |

| Fe2O3, % | ≤ | 0.2 | 0.2 | 0.3 |

| Bulk Density, g/cm3 | ≥ | 3.2 | 3 | 2.8 |

| Apparent Porosity, % | ≤ | 19 | 18 | 18 |

| Cold Crushing Strength, MPa | ≥ | 100 | 100 | 100 |

| 0.2MPa Refractoriness Under Load, ℃ | ≥ | 1700 | 1700 | 1700 |

Kerui Corundum Brick

Corundum bricks are high temp refractory bricks made from corundum through sintering or electric melting processes. The corundum is a mineral form of aluminum oxide (Al2O3). It boasts a high aluminum oxide content of over 99%. So, the brick is characterized by exceptional hardness, mechanical strength, and refractoriness.

Corundum bricks can be combined with other mineral materials to create composite refractory bricks, such as chrome corundum bricks, zirconia corundum bricks, corundum mullite bricks, etc. These composite bricks offer superior performance and structure. These features make them ideal for various high-temperature industrial applications.

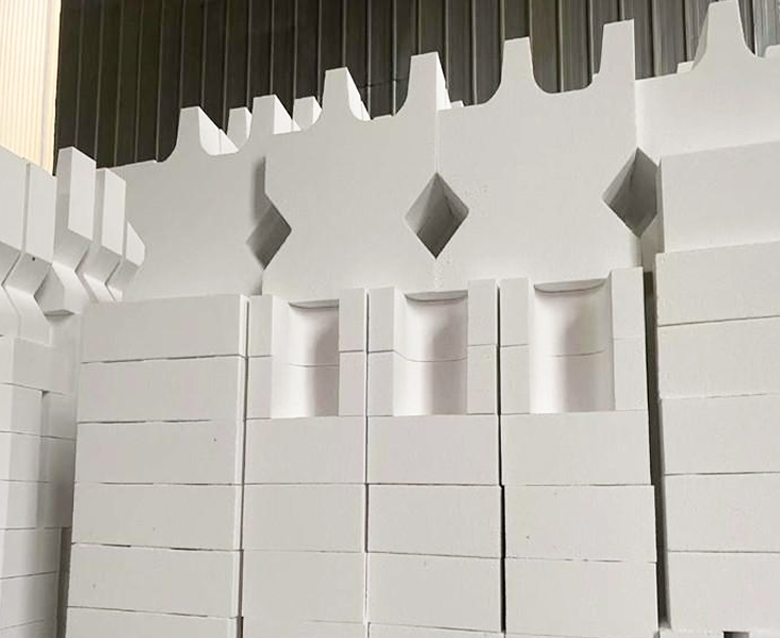

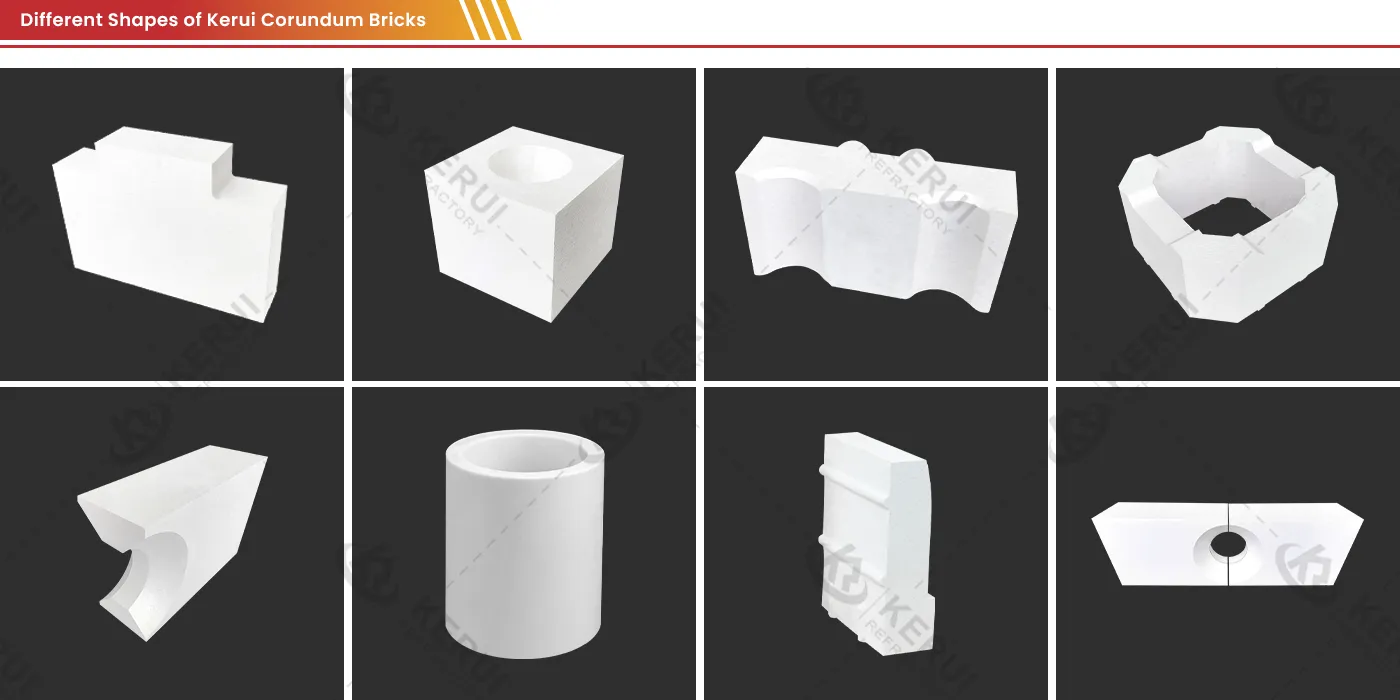

Different Shapes of Kerui Corundum Refractory Brick

In addition to standard straight corundum bricks, we also provide the following special brick types, including universal arc bricks, anchor bricks, half bricks, knife-axe bricks, etc.

Video of Kerui Corundum Brick

Advantages of Kerui Corundum Brick

-

High refractoriness

Corundum bricks exhibit exceptional refractoriness. Corundum is among the most refractory materials available. So, the brick has a load-softening temperature exceeding 1700°C.

-

High mechanical strength

These bricks possess remarkable hardness. They boast a cold-pressing strength of up to 340 MPa. This translates to superior load-bearing capacity in high-temperature applications.

-

Excellent thermal insulation

Corundum bricks feature low thermal conductivity. They provides exceptional thermal insulation and heat retention properties.

-

Strong resistance to chemical corrosion

Even at high temperatures, corundum bricks remain unaffected by acidic and alkaline chemically corrosive media. Therefore, it enables long-term use in harsh chemical environments.

Applications of Kerui Corundum Brick

Due to their exceptional refractoriness and chemical stability, corundum bricks find extensive applications in high-temperature industrial environments. They are commonly employed as linings for critical components within high-temperature furnaces, steel ladles, furnace linings, pipes, rails and so on.

- Iron and steel metallurgy: Steelmaking furnaces, non-ferrous metal smelting furnaces, heating furnaces, blast furnaces, hot blast stoves, and so on.

- Construction materials industry: Glass melting furnaces, cement kilns, lime kilns, ceramic kilns, and so on.

- Petrochemical industry: Petrochemical furnaces, reactors, refining furnaces, ammonia synthesis furnaces, and so on.

- Power industry: Waste incineration furnaces, and so on.

Contact Rich-experienced Kerui Refractory

Kerui Refractory has 20+ years of experience in refractory industry. We have large-area factory, international certificates, patents and professional team. And we provide quality products and refractory solutions to partners. We have served 2000+ partners all over the world. If you have this need, contact us. Our professional team will offer the most suitable solution to you. View Kerui news on Linkedin.