Chrome Corundum Brick

Chrome corundum bricks are high-grade refractory materials. They resist high temperatures and slag erosion. They form a solid solution barrier. These bricks are key linings for incinerators, gasifiers, glass kilns, and metallurgical furnaces. Kerui has over 20 years of experience. We have provided solutions to over 50 customers. We also offer turnkey EPC services.

- Free Sample:

- Available

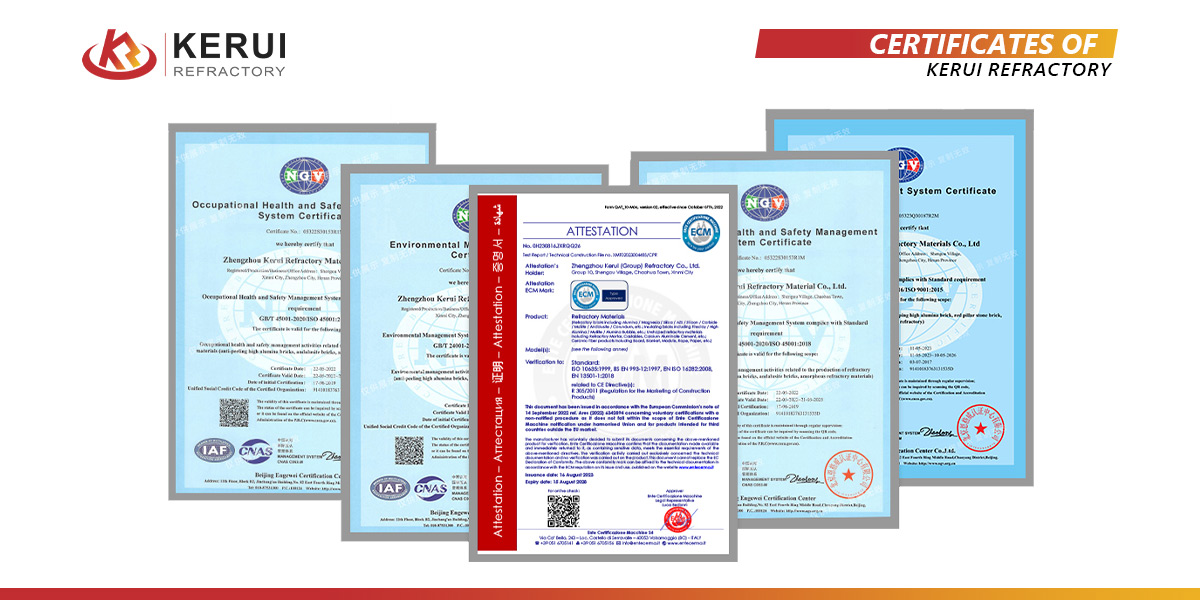

- Document:

- Certificates Supporting

- Performance Test:

- Support

- Shipment:

- 7-35 working days globally

Technical Data of Kerui Chrome Corundum Brick

| Item | GGZ-30 | GGZ-20 | GGZ-12 | GGZ-5 | |

|---|---|---|---|---|---|

| Cr2O3, % | ≥ | 30 | 20 | 12 | 5 |

| Fe2O3, % | ≤ | 0.3 | 0.3 | 0.3 | 0.3 |

| Al2O3, % | ≥ | 68 | 76 | 80 | 85 |

| Apparent Porosity, % | ≤ | 18 | 18 | 18 | 18 |

| Bulk Density, g/cm3 | ≥ | 3.5 | 3.4 | 3.2 | 3.1 |

| Cold Crushing Strength, MPa | ≥ | 100 | 100 | 100 | 100 |

Chrome Corundum Brick Color Indicates Composition And Process

Chrome corundum bricks contain Cr₂O₃. Their main mineral phase is an Al₂O₃-Cr₂O₃ solid solution.

These bricks appear green initially. This green color comes from chromium oxide in the corundum. After high-temperature firing, a reaction with CO occurs. This reaction changes their appearance to red, sometimes even purplish-red.

The brick’s color depends on the chromium oxide (Cr₂O₃) percentage:

- 3% Cr₂O₃: Light red;

- 8% Cr₂O₃: Purplish-red;

- Over 20% Cr₂O₃: Blackish-red;

- A higher chromium oxide percentage creates a darker brick color.

Sizes of Chrome Corundum Brick

Standard Shapes: Standard rectangular bricks (230×114×65mm), thickened bricks, etc.

Shaped Bricks: steel ladle bricks, slide rail refractory bricks, breathable bricks, burner bricks, etc. These are primarily used in special structural parts of equipment such as steel ladles, gasifiers, waste incinerators, and glass furnaces, offering features like abrasion resistance and corrosion resistance.

If you need different types of bricks, you can offer the specifications. We also have technicians who can provide customized services according to your needs.

Features of Chrome Corundum Refractory Bricks

Stable Chemical Capacity

Chrome corundum bricks have great chemical resistance. They can resist acid and alkaline solutions. Besides, the chromic oxide can form a protection film that can avoid slag erosion.

High Refractoriness

Chrome and corundum both have high melting points. So the under load temperature of chrome corundum brick is up to 1700℃. In this situation, chrome corundum bricks can be used in many high-temperature industrial kilns.

Good Thermal Shock Resistance

In the production process, chrome and corundum can form a continuous solid solution. This structure can effectively improve the hardness of bricks. So the hardness of chrome corundum brick is better than corundum brick.

Oxidation Resistance

Chrome corundum refractory brick has good oxidation resistance. It will not oxide with other materials in the high-temperature equipment. In this situation, it belongs to environment-friendly material that can be reused.

Different Types of Chrome Corundum Refractory Bricks

| Brick Type | Key Composition | Core Properties & Mechanisms | Typical Applications |

|---|---|---|---|

| Corundum Brick | Al₂O₃ ≥90% | – High temp resistance, High strength, Good erosion resistance | General linings for high-temperature furnaces (e.g., cracking furnaces, blast furnaces) |

| Chrome Corundum Brick | Al₂O₃ + Cr₂O₃ *(Content typically 5%-30%)* |

– Superior slag resistance: Cr₂O₃ forms solid solution with Al₂O₃, blocking slag penetration – Higher refractoriness – Sintered vs. Fused: Sintered offers better thermal shock; Fused is denser |

Slag-prone environments: waste incinerators, gasifiers, glass furnace regenerators |

| Zirconia Corundum Brick (AZS) | Al₂O₃ + ZrO₂ *(ZrO₂ 33%-45%)* |

– Exceptional resistance to molten glass erosion: ZrO₂ is non-wetting to glass melt – Fused vs. Sintered: Fused is denser; Sintered has better thermal shock resistance |

Primary use in glass melting furnaces (e.g., tank walls, throat) |

| α/β-Alumina Electrofused Brick | Predominantly β-Al₂O₃ (Produced by fusion casting) |

– Very low apparent porosity, High resistance to gas/alkali vapor attack – Drawback: Poor high-temperature volume stability |

Superstructure in glass furnaces, carbon black reactors—environments with alkali vapors |

| Corundum Mullite Brick | Corundum + Mullite | – Excellent thermal shock resistance: Mullite’s low thermal expansion buffers thermal stress – Well-balanced high-temperature properties |

Applications with frequent thermal cycling: ceramic kiln furniture, hot blast stoves |

| Chrome Zirconia Corundum Brick | Al₂O₃ + Cr₂O₃ + ZrO₂ | – Combines advantages of Chrome & Zirconia: Slag resistance + glass corrosion resistance & thermal shock improvement – Enhanced thermal shock resistance |

Complex corrosive environments: glass furnace regenerators, demanding waste melting furnaces | High Chrome Brick | Very High Cr₂O₃ (Typically >70%, up to >90%) |

– Top-tier resistance to acidic slag & iron slag – Drawbacks: High density, high thermal conductivity, potential Cr⁶⁺ leaching |

Extremely severe slag corrosion environments: coal gasifier slag zones, copper smelting furnaces |

| Lightweight Corundum Brick | High Al₂O₃, containing numerous pores | – Light weight, Excellent thermal insulation – Drawback: Low strength and erosion resistance |

Insulation layer in industrial furnaces, not in direct contact with melt or gas |

Usages of Chrome Corundum Bricks

Compared with corundum brick, chrome corundum brick is used more widely.

- Glass industry: glass kiln lining, brushed glass flow hole cover brick, and so on.

- Steel industry: hot blast furnace lining, bottom, throat, ladles, and other equipment.

- Nonferrous industry: melting furnaces, converters, anode furnaces, etc.

- Petrochemical industry: thermal reactors, waste incinerators, etc.

High Quality of Chrome Corundum Bricks

In our factory, we have built quality control laboratories to strictly control product quality. We have passed the inspection of international institutions and got the certificates including ISO, CE, and SGS. Besides, we have professional quality control personnel in every production line.

Strength of Kerui

Kerui has a factory to produce refractory materials. In this situation, we can provide a suitable price for chrome corundum brick. Kerui has a lot of export experience. Our refractory products have been exported to many countries including Russia, Jordan, Italy, Vietnam, and so on. Finally, we have technicians to give professional advice to every customer. We also provide construction guidance and turnkey service to customers. The profession of Kerui is worthy of your trust. View more products on Kerui Pinterest.