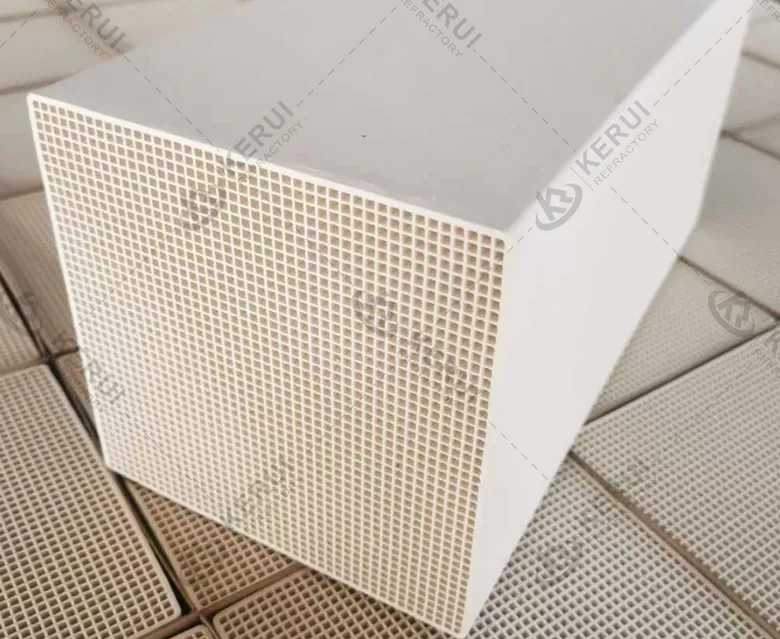

Ceramic Honeycomb

Honeycomb ceramic regenerators are the core components of regenerative burners. They are widely used in Regenerative Thermal Oxidizer (RTO) systems or regenerative heating furnaces across various industrial sectors. These regenerators help recover waste heat from flue gases, thereby saving fuel. Kerui offers honeycomb ceramic regenerators made from materials such as corundum mullite, high alumina, and cordierite.

- Free Sample:

- Available

- Document:

- TDS supporting

- Performance Test:

- Support

- Shipment:

- 7-30 working days globally

Specifications of Honeycomb Ceramic Regenerators

| Category | Details / Options |

|---|---|

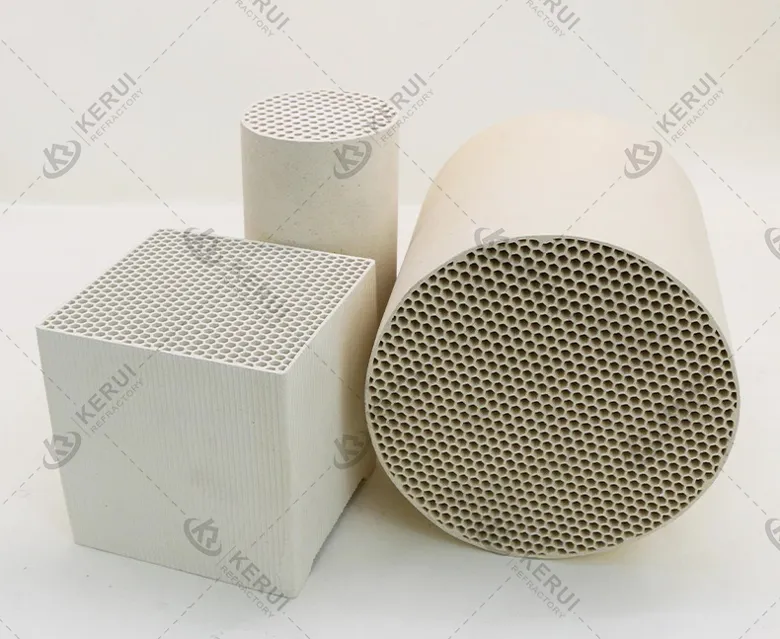

| Material | Corundum Mullite, High Alumina, Cordierite |

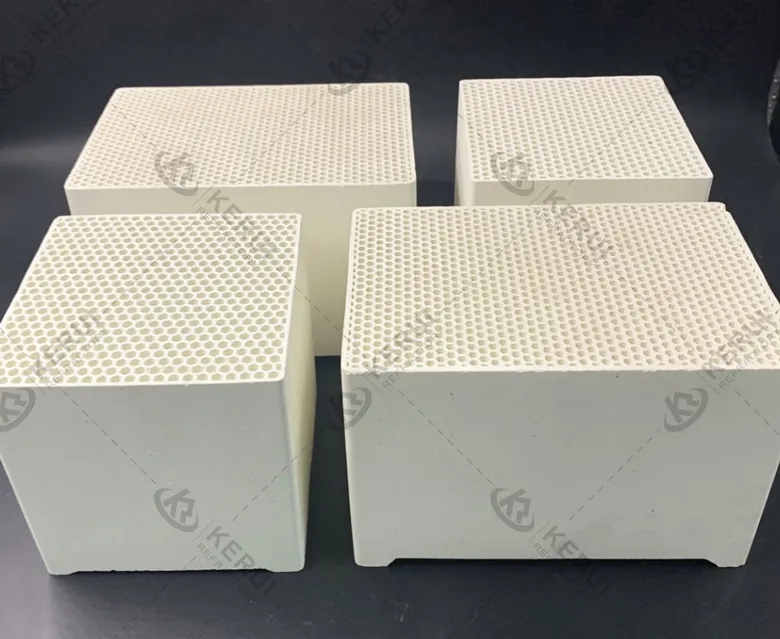

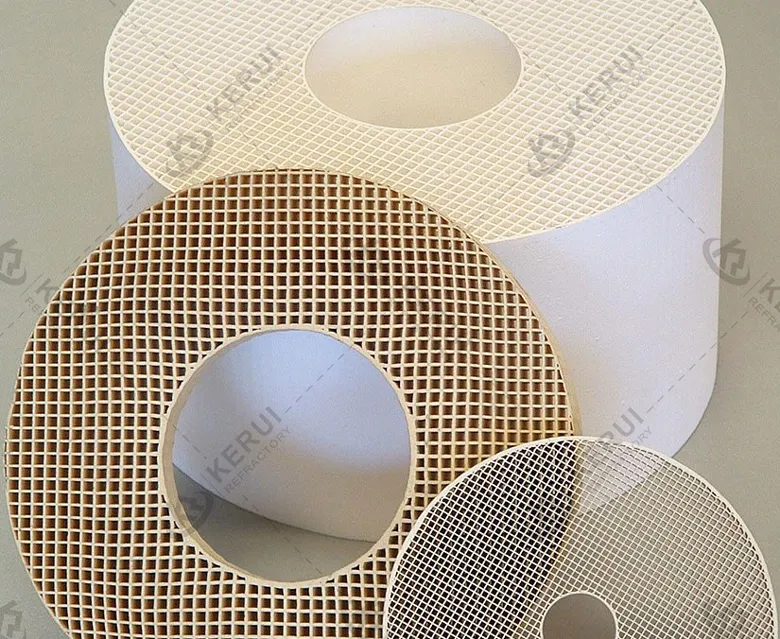

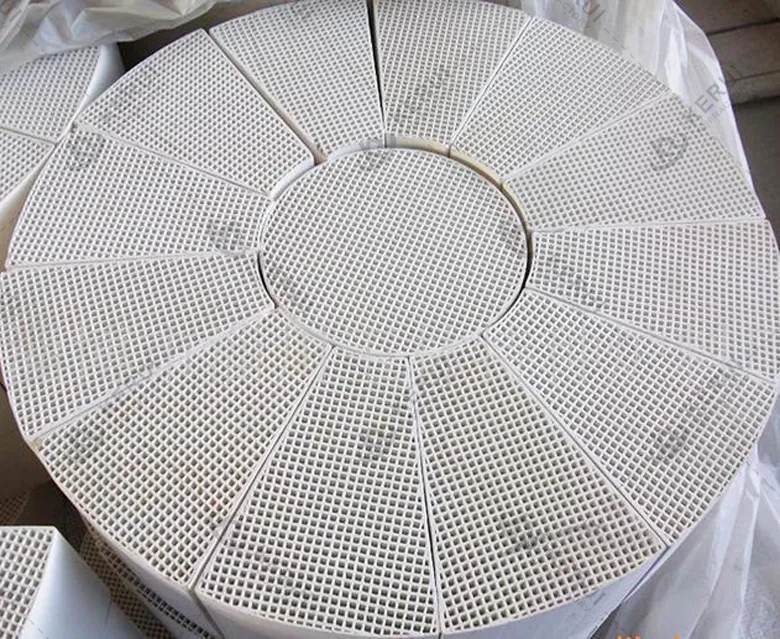

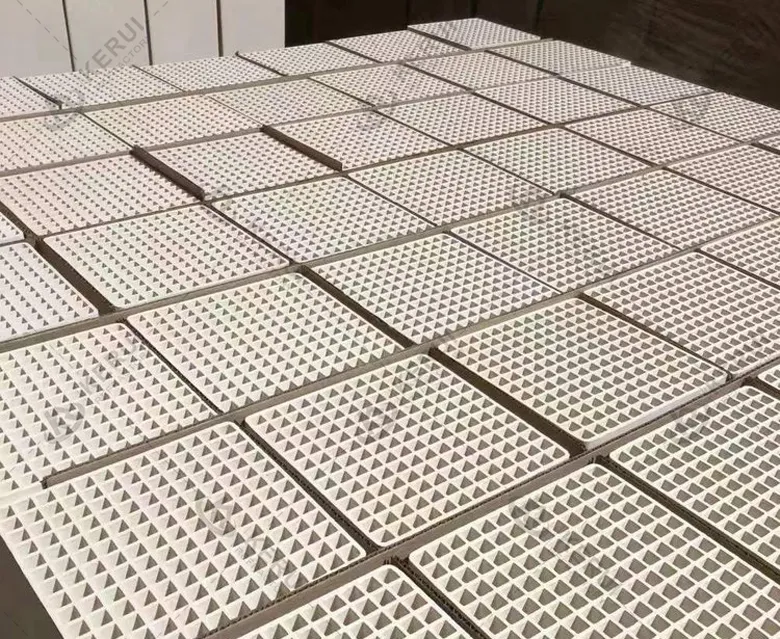

| Cell Shape | Triangular, Square, Circular, Hexagonal |

| Dimensions (mm) | 100×100×100, 100×150×150, 150×100×100, 150×150×150, 150×150×300 |

| Customization | Non-standard sizes available for bulk orders (Contact us for details) |

| Note | Please confirm cell shape and cell density (CPCI) before purchase |

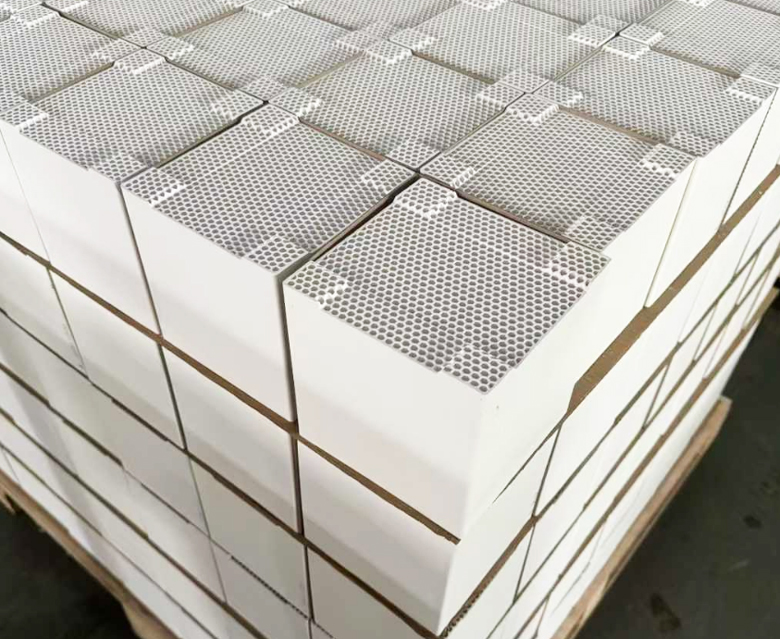

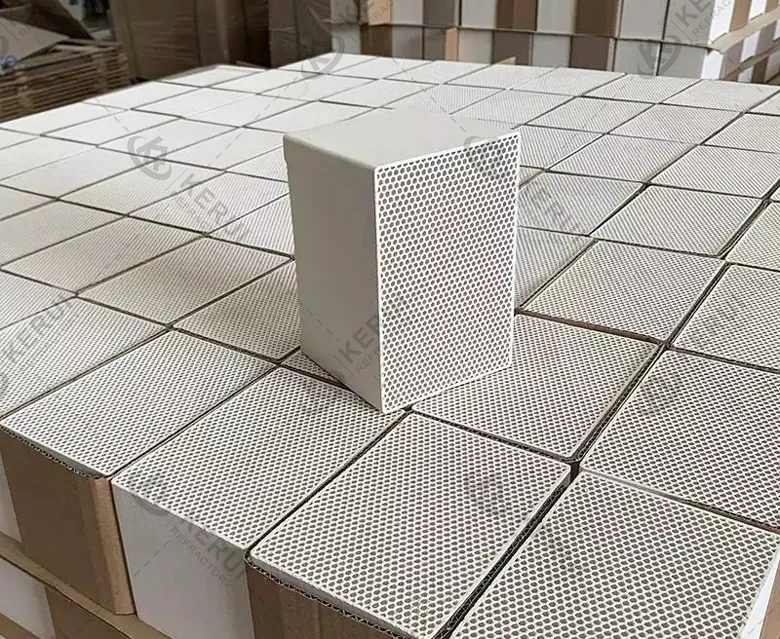

Export Packaging Specifications

- External Packaging: Kerui uses export-specific wooden pallets or reinforced wooden cases;

- Internal Separation: Each layer of regenerators is separated with protective isolating material;

- Side Reinforcement: Fully wrapped with thickened cardboard or plywood on all sides;

- Marking Requirements: Clear shipping marks on all sides, including product information and moisture/fragile warnings.

Core Features of Honeycomb Ceramic Regenerators

- High-Efficiency Heat Transfer:

The honeycomb channels significantly increase the contact area, enabling highly efficient heat exchange between hot gas and the ceramic, resulting in exceptional thermal efficiency. - Energy and Cost Savings:

With a heat recovery rate exceeding 90%, it effectively preheats combustion air, substantially reducing fuel consumption, operational costs, and emissions. - High-Temperature and Corrosion Resistance:

Constructed with advanced refractory materials, it withstands temperatures over 1300°C, resists thermal shock, and offers excellent resistance to chemical corrosion, ensuring a long service life. - Low-Pressure Drop Operation:

The smooth and streamlined channels minimize airflow resistance, reducing energy consumption of fan systems. - Compact and Robust Structure:

Its modular design provides high strength, exceptional heat storage capacity, space efficiency, and outstanding pressure resistance and durability. - Rapid Thermal Response:

Capable of quick heat absorption and release, it supports frequent switching cycles, ensuring stable and continuous system temperature maintenance. - Uniform Cell Density and Thin Walls:

Increased cell density per unit area and reduced wall thickness enhance thermal shock resistance while raising the critical temperature for thermal damage.

Technician Data of Ceramic Honeycomb

Honeycomb ceramic regenerators act as passive “heat transporters” and temporary “thermal storage units,” efficiently exchanging heat between high-temperature exhaust gas and low-temperature gas. This process significantly enhances the thermal efficiency of industrial furnaces and other thermal equipment. Typically, it is used in conjunction with checker bricks and baffle fire bricks. Please refer to the parameter specifications below.

| Material | Corundum Mullite |

| Al₂O₃ | 65-70% |

| SiO₂ | 25-30% |

| Fe₂O₃ | <1.5% |

| Bulk Density (kg/m³) | 700-1150 |

| Thermal Expansion Coefficient (×10⁻⁶/°C) | ≤5.5 |

| Thermal Conductivity (W/m·K) | ≥1.0 |

| Maximum Working Temperature (°C) | 1550 |

| Compressive Strength – Direction A – Direction B |

>26.0 MPa >10.5 MPa |

Main Application Fields of Ceramic Regenerators

Ceramic regenerators are critical components in RTO (Regenerative Thermal Oxidizer) heat exchange treatment systems for energy-intensive industries, enabling significant energy savings and emission reductions:

- Industrial Waste Gas Treatment (VOCs Abatement)

RTO units, whose core component is the ceramic regenerator, are the mainstream technology for treating volatile organic compounds (VOCs), achieving heat recovery efficiency exceeding 95%. - Iron and Steel Metallurgy Industry

Used in High-Temperature Air Combustion (HTAC) burners, blast furnace hot blast stoves, steel rolling heating furnaces, and coke ovens to preheat combustion air to over 1000°C, significantly reducing the fuel ratio in iron and steelmaking processes. - Glass Industry

Applied in regenerators of glass melting furnaces to recover waste heat from flue gas for preheating air and gas, serving as an indispensable link in glass production. - Chemical and Petrochemical Industry

Utilized in cracking furnaces, reforming furnaces, and other equipment to improve thermal efficiency in industrial processes. - Ceramics and Building Materials Industry

Employed in tunnel kilns and roller kilns to reduce energy consumption during product firing. See some YouTube videos.