Calcium aluminate cement (CAC) is a type of hydraulic refractory cement. It solidifies within 6 hours at 25-35 degrees Celsius. Additionally, its flexural strength and compressive strength are enhanced within 24 hours. Compared to common Portland cement, this cement has higher early strength and faster setting time. Kerui exported this product to 50+ countries. And we received good reviews.

- Al2O3: ≥50-81%;

- Compressive Strength (72h): 40-82MPa;

- Initial Setting Time: 30-240min;

- Final Setting Time: 90-360min;

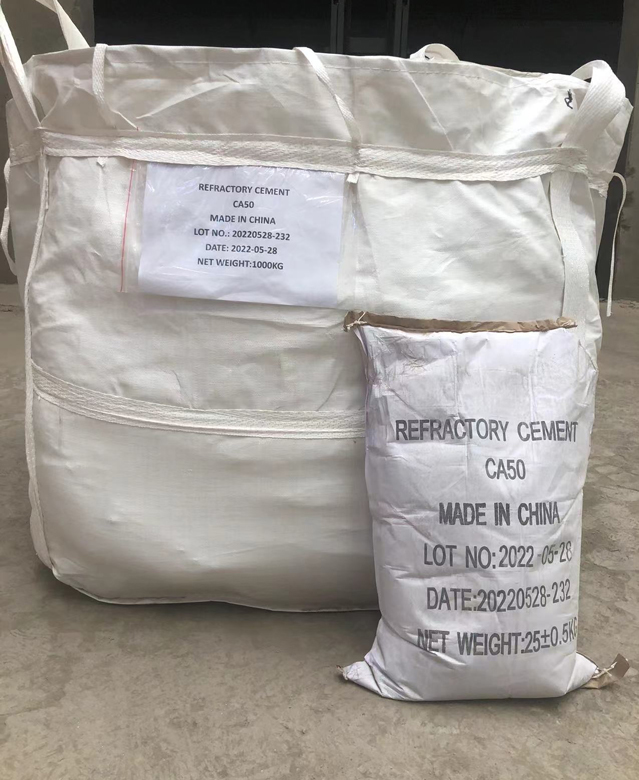

- Packaging: 25kg/bag; 1000kg/bag;

- Delivery: 7-15 working days;

Choose Suitable Type of Calcium Aluminate Cement

Calcium aluminate cement is mainly divided into CA50, CA70, and CA80 according to the content of Al203.

CA50

- Al203: ≥20.0-53.5%;

- Raw materials: natural bauxite and limestone;

- Mineral phase: CA, C12A7, C2AS, CT;

- Refractory degree: 1300-1350℃;

CA70

- Al203: 68.5-70.5%;

- Raw materials: industrial alumina and high-purity limestone;

- Mineral phases: CA, CA2, C12A7, C2AS, Aa;

- Refractory degree: 1580-1650℃;

CA80

- Al203: 78.0-81.0%;

- Raw materials: industrial alumina and high-purity limestone;

- Mineral phases: CA, CA2, Aa, and C12A7;

- Refractory degree: 1580-1650℃;

Specifications of Calcium Aluminate Cement – CA50/CA70/CA80

Type 1. Cac Cement CA50

| Item | A600 | A700 | A900 | ||

|---|---|---|---|---|---|

| SiO2, % | ≤ | 7.8 | 7.5 | 5.5 | |

| Al2O3, % | ≥ | 50.0 | 51.0 | 53.5 | |

| Fe2O3, % | ≤ | 2.5 | 2.5 | 2.5 | |

| R2O, % | ≤ | 0.4 | 0.4 | 0.4 | |

| S, % | ≤ | 0.1 | 0.1 | 0.1 | |

| CI, % | ≤ | 0.1 | 0.1 | 0.1 | |

| 325M Residue on Sieve, % | ≤ | 15 | 12 | 8 | |

| S, m²/kg | ≥ | 300 | 320 | 350 | |

| Initial Setting Time, min | ≥ | 45 | 60 | 90 | |

| Final Setting Time, h | ≤ | 6 | 6 | 6 | |

| Flexural Strength, Mpa | 1d | ≥ | 6.0 | 6.5 | 8.0 |

| 3d | ≥ | 7.0 | 7.5 | 10.0 | |

| Compressive Strength, Mpa | 1d | ≥ | 45 | 55 | 72 |

| 3d | ≥ | 55 | 65 | 82 | |

Type 2. Cac Refractory Cement CA70

| Item | CA70 | |

|---|---|---|

| Properties Determined according to GB201-2000 | ||

| SiO2,% | ≤0.5 | |

| Al2O3,% | 68.5-70.5 | |

| FeO3,% | ≤0.2 | |

| CaO,% | 28.5-30.5 | |

| MgO,% | ≤0.4 | |

| R2O,% | ≤0.4 | |

| Fineness | D50, um | 11-14 |

| 45um, % | ≤8.0 | |

| Setting Time, min | Initial Setting, IS | 120-180 |

| Final Setting, FS | 150-240 | |

| Flexural Strength, Mpa | 1d | 7.5-10.0 |

| 3d | 10.0-12.0 | |

| Compressive Strength, Mpa | 1d | 40-50 |

| 3d | 45-55 | |

| Cement Properties in Testing Castables | ||

| Setting Time, min | 20°C | 60-90 |

| 35°C | 30-50 | |

| Vibration Flow, mm (20°C) | Initial Flow | 265-275 |

| 10min | 255-265 | |

| 30min | 235-245 | |

| 60min | 230-240 | |

| Flexual Strength, Mpa | 20°C*24h | 4.5-5.5 |

| 110°C*24h | 10.0-11.5 | |

| 1100°C*4h | 12.0-14.0 | |

| Compressive Strength, Mpa | 20°C*24h | 35-45 |

| 110°C*24h | 85-95 | |

| 1100°C*4h | 100-120 | |

| Linear Change, % | 1100°C*4h | ≤-0.25 |

Type 3. Cac Cement CA80

| Item | CA80 | |

|---|---|---|

| Properties Determined according to GB201-2000 | ||

| SiO2, % | ≤0.5 | |

| Al2O3, % | 78.0-81.0 | |

| Fe2O3, % | ≤0.2 | |

| CaO, % | 17.5-20.5 | |

| MgO, % | ≤0.4 | |

| R2O, % | ≤0.4 | |

| Fineness | D50, μm | 5-8 |

| -45μm, % | ≤5.0 | |

| Setting Time, min | Initial Setting, IS | 30-90 |

| Final Setting, FS | 90-180 | |

| Flexural Strength, Mpa | 1d | 5.0-7.5 |

| 3d | 6.0-8.5 | |

| Compressive Strength, Mpa | 1d | 30-40 |

| 3d | 40-50 | |

| Cement Properties in Testing Castables | ||

| Setting Time, min | 20℃ | 90-120 |

| 35℃ | 40-60 | |

| Vibration Flow, mm (20℃) | Initial Flow | 255-265 |

| 10min | 250-260 | |

| 30min | 240-250 | |

| 60min | 235-245 | |

| Flexual Strength, Mpa | 20℃*24h | 3.0-4.0 |

| 110℃*24h | 8.0-9.0 | |

| 110 *24h | 11.0-13.0 | |

| Compressive Strength, Mpa | 20℃*24h | 25-35 |

| 110℃*24h | 60-70 | |

| 1100℃*4h | 100-120 | |

| Linear Change, % | 1100℃*4h | ≤-0.15 |

Quality Production of Calcium Sulphoaluminate Cement

High-quality materials: Kerui calcium aluminate cement is a refractory cement made by melting high-quality aluminum and calcium in proportion at high temperatures. The mixture of limestone and alumina forms hydraulic calcium aluminate. This material has a refractoriness of over 1500 degrees Celsius. It works stably in high-temperature situation. After simple hydration, partners can use this material directly.

Excellent production: The calcium aluminate cement for sale produced by Kerui undergoes the following testing processes, aluminum and calcium material testing, raw material size screening, precise proportioning, high-tech production, finished product quality testing, and so on. We offer high-quality and factory calcium aluminate cement prices for every partner.

Outstanding Characteristics of Calcium Alumina Cement

- High early strength: The main component CA phase has a fast hydration rate and high early strength. It can also perform well in cold weather.

- Rapid setting: The final setting time is generally within 6 hours. The setting time is short and the final strength is high.

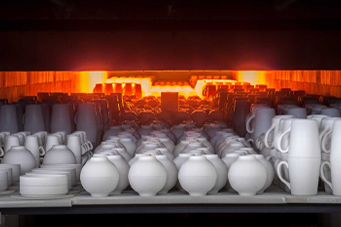

- High-temperature resistance: The alumina content is higher than 50%. This point gives this cement excellent high-temperature resistance.

- Corrosion resistance: Due to the calcium and mineral components, this cement has good resistance to acid and alkali corrosion.

- Wear resistance: The good density, stable mineral composition, and high strength of calcium aluminate cement contribute to its excellent wear resistance.

- Short construction period: This amorphous material can be constructed in a short period of time. Its shape can be controlled as desired. This material provides great convenience to partners.

Wide Calcium Aluminate Cement Uses

-

- Adhesive: This material with multiple excellent properties is widely used in high-performance adhesives.

It is a good material for conjunction with other amorphous refractory materials, such as refractory mortar and refractory castables. Its main applications include chimney coatings, tunnels, roads, pipelines, and so on.

It serves as an adhesive between different materials, such as refractory bricks. Its main applications include chemical plants, petroleum tanks, and so on.

- Occasions: Require rapid hardening, repair, sealing, chemical erosion, and so on.

- Industries: Refractories, ceramics, glass, steel smelting, chemical industry, power generation, construction, and so on.

2000+ Partners Choose Kerui Calcium Aluminate Cement

Over 2000 customers choosing Kerui Refractory due to our extensive production and export experience, including RUSAL, CHALCO, ALBA, POSCO, PSM, etc.. we provide our partners with a diverse range of calcium aluminate cement and refractory solutions. These partners are highly satisfied with our products and after-sales services, and they continue to repurchase our products.

Kerui – The World’s Leading Manufacturer

- Factory with a 250,000-ton annual production capacity has large and stable production ability;

- Digitalized and automated production system ensures fast and high-quality production;

- Numerous international certifications, patents, and corporate honors guarantee product quality.

Kerui Services for Partners

- One-on-one professional consulting service;

- Expert guidance on calcium silicate cement products;

- High-quality, complete packaging to ensure quality;

- High-temperature kiln application solutions;

- Wide range of calcium aluminate cement options;

- Supported by over 20 experienced technical personnel;

- Fast shipping;

- Optimal packing and shipping route selection. See some Pinterest pictures.

- Construction guidance service.