AZS refractory brick exhibits excellent refractory properties and chemical stability. It is commonly used in the high-temperature glass industry. Kerui Refractory provides AZS41, AZS36, and AZS33 to 2000+ customers from 50 countries. Kerui provides different sizes

- ZrO2: 33.5-41%;

- SiO2: 12-15%;

- Bulk Density: 3.8-4.05g/cm³;

- Cold Crushing Strength≥70MPa;

- Apparent Porosity: 0.6-0.8%;

- Size: Customized sizes available;

- Delivery: 15-30 working days;

Technique Parameters of Fused Cast Refractories

Kerui Refractory offers three types, including AZS-41# brick, AZS-36# brick, AZS-33# brick. The numbers 41, 36, and 33 represent the range of ZrO2 content in the heat refractory bricks. For example, AZS-41 contains 41% ZrO2. Please choose the appropriate product according to your needs and AZS properties.

| Item | AZS41 | AZS36 | AZS33 |

|---|---|---|---|

| SiO2, % | 12 | 13 | 15 |

| Al2O3, % | The Remainder | The Remainder | The Remainder |

| ZrO2, % | 41 | 36.5 | 33.5 |

| Fe2O3+TiO2+CaO+MgO+Na2O+K2O, % | ≤2.0 | ≤2.0 | ≤2.0 |

| Bulk Density, g/cm3 | 4.05 | 3.9 | 3.8 |

| Apparent Porosity, % | 0.6 | 0.8 | 0.7 |

| Initial Precipitation Temperature of Vitreous Phase, ℃ | 1400 | 1400 | 1400 |

| Vitreous Phase Exudation, % (1500℃*4h) | 1.5 | 2.3 | 2.0 |

| Anti-molten Glass Erosion Speed Under Static Condition, mm/24h (1500℃*36h, ordinary soda lime glass) | 1.2 | 1.3 | 1.4 |

| Bubble Release Rate, % (1300℃*10h, ordinary soda lime glass) | 0.6 | 1.0 | 1.2 |

Introduction of Kerui AZS Refractory Brick

AZS refractory bricks are short for electrofused Alumina-Zirconia-Silica refractory bricks. This high content of alumina and zirconia improves the brick’s fire resistance, thermal shock resistance and corrosion resistance. AZS bricks perform well in high-temperature environments and make them ideal in many industrial applications, like glass furnaces.

Kerui offers customized AZS bricks and support pre-assembly in the factory.

Types and Applications of AZS Bricks

| Property / Parameter | AZS-33# Brick | AZS-36# Brick | AZS-41# Brick |

|---|---|---|---|

| Picture |  |

|

|

| Zirconia (ZrO₂) Content | 33% ± 1% | 36% ± 1% | 41% ± 1% |

| Resistance to Glass Liquid Erosion | ★★★☆☆ | ★★★★☆ | ★★★★★ |

| High-Temperature Pollution Resistance | ★★★☆☆ | ★★★★☆ | ★★★★★ |

| Bulk Density/Compactness | ★★★☆☆ | ★★★★☆ | ★★★★★ |

| Reference Price | ★★★☆☆ | ★★★★☆ | ★★★★★ |

| Primary Application Scenarios | ★ Upper Furnace Structure: Breast walls, burner ports, upper checkerwork ★ Secondary Contact Areas: Melting tank areas with lower quality requirements |

★ General Key Areas: Melting tank sidewalls, doghouses, working end ★ Critical Non-Core Parts: Throat cover blocks, some paving blocks |

★ Severe Erosion Zones: Throat, weir, bubbling blocks ★ High-Quality Glass Zones: Contact areas for ultra-clear & electronic glass |

A Guide to AZS Casting Methods for Your Needs

To meet diverse furnace needs, Kerui AZS bricks use different casting processes. Each type fits specific applications and performs differently. We can help you select the right type accurately.

| Casting Type | Shrinkage Characteristics | Porosity | Erosion Resistance | Cost | Applications |

|---|---|---|---|---|---|

| Regular Cast (PT) | Concentrated shrinkage (3-5%) | 3-5% | ★★☆☆ | Low | Non-contact zones, flues |

| Tilt Cast (QX) | One-sided shrinkage (1-2%) | 1-2% | ★★★☆ | Medium | Transition zones, burner ports |

| Void Free (WS) | Micro-dispersed (<1%) | 0.8-1% | ★★★★ | Medium-High | Critical shaped parts (feeder channels) |

| End Cut (ZWS) | No macro-shrinkage | <0.5% | ★★★★★ | High | High-temperature contact zones (tank walls) |

Applications of Fused Cast AZS Block

AZS bricks are widely used in various industries, including glass industry for tank furnaces and glass electric furnaces, steel industry for slide gates, caustic soda industry for kilns, aluminum electrolysis cells, silicon stone melting furnaces, phosphate industry kilns, and so on.

More importantly, Kerui Refractory can design solutions tailored to your specific usage scenarios, such as kiln design. Refractory manufacturers have a professional engineering team and technical staff who can provide customized solutions based on customer needs and requirements. The right solution ensures optimal performance and applicability of the products.

Advantages of Kerui Fused Cast AZS Brick

Excellent Erosion Resistance

Zirconium oxide (ZrO₂) crystals provide superior resistance to chemical corrosion and physical erosion from molten glass.

Outstanding High-Temperature Performance

Maintains structural integrity and resists deformation under high temperatures for stable furnace operation.

Superior Resistance to Glass Phase Exudation

Increased ZrO₂ content reduces glass phase exudation, preventing contamination of molten glass.

High Mechanical Strength and Wear Resistance

Dense fused cast structure with zirconium oxide reinforcement ensures exceptional durability.

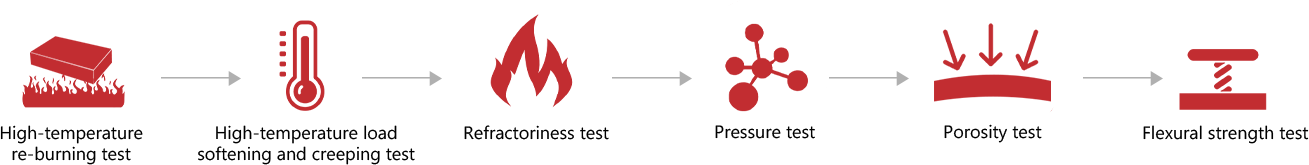

Test of Fused Cast AZS Brick

After each batch of AZS bricks is produced, Kerui Refractory will randomly select samples for testing. After passing the inspection, it will be sent to the customers. This step ensures that the AZS bricks delivered to customers meet the requirements. The testing process mainly includes the following aspects:

Global Customers of Kerui AZS Refractory Bricks

Kerui AZS bricks and solutions have been applied in over 50 countries across five continents globally. These customers have expressed that Kerui provides high-quality refractory bricks, professional technical support, and comprehensive after-sales service. And they will continue to choose to cooperate with Kerui Refractory in the future if there is a need.

Certificates of Kerui Fused Cast AZS

Kerui Refractory and AZS hold international certificates and patents such as ISO9001, ISO14001, OHSAS18001, CE, SGS, and so on. These certifications show Kerui Refractory’s dedication to quality, environmental management, occupational health and safety, and compliance with global standards. By following these certifications, Kerui Refractory guarantees that its AZS bricks are made and delivered with top-notch quality, safety, and environmental responsibility.

Choose Kerui Refractory As Fused Cast AZS Manufacturer

Factory Strength

Kerui Refractory has its own AZS brick manufacturing factory. Twenty sets of pressure equipment and two 168-meter natural gas tunnel kilns enable us to deliver AZS bricks to customers on time and with high quality. In addition, the factory’s production team, equipment, and quality inspection team. The shipping team consistently serves customers with a professional attitude.

Technical Strength

Kerui Refractory has a professional technical team with over 20 years of industry experience to provide customers with professional comprehensive solutions and product plans for AZS blocks. Even if customers are new to this industry, they do not need to worry.

Service Strength

We offer construction and training services of AZS brick solution. Our construction team will assist customers in completing projects on time. Additionally, we provide technical online consultation services to address customers’ inquiries promptly.

As the leading manufacturer of AZS bricks, Kerui Refractory prides itself on our commitment to quality, innovation, and customer satisfaction. Our expertise and dedication to meeting customers’ specific needs sets us apart in the industry. When you choose us, you can trust that you are getting a reliable and durable product that will meet your high-temperature industrial requirements. Experience the difference with our AZS bricks and let us be your trusted partner in success. Let’s discuss on Email or Kerui WhatsApp.