Anchor refractory brick is a refractory material used to secure refractory materials and linings. Kerui offers a wide range of high-quality bricks made from materials such as alumina, kaolin, silica, magnesia, and so on. As a direct manufacturer, we provide customers with high-quality, controllable products and solution guidance services.

- Refractoriness: 1750℃;

- Al2O3: ≥55-80%;

- Bulk Density: 2.15-2.8g/cm³;

- Refractoriness Under Load: 1450ºC;

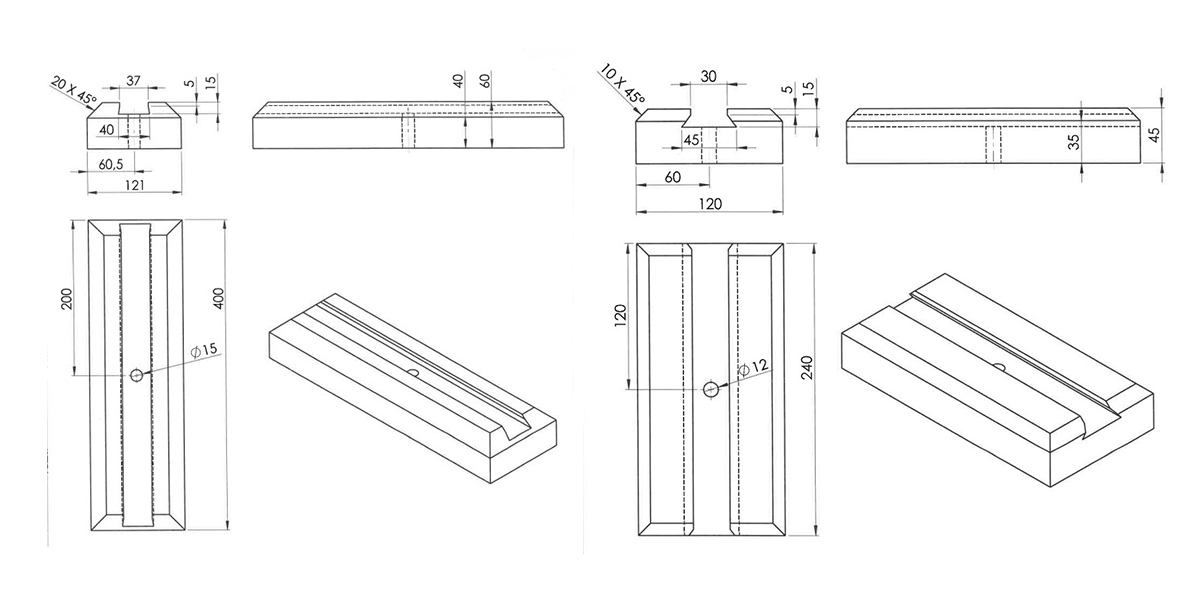

- Size: Common/And Customizable sizes;

Parameters of Anchor Refractory Bricks

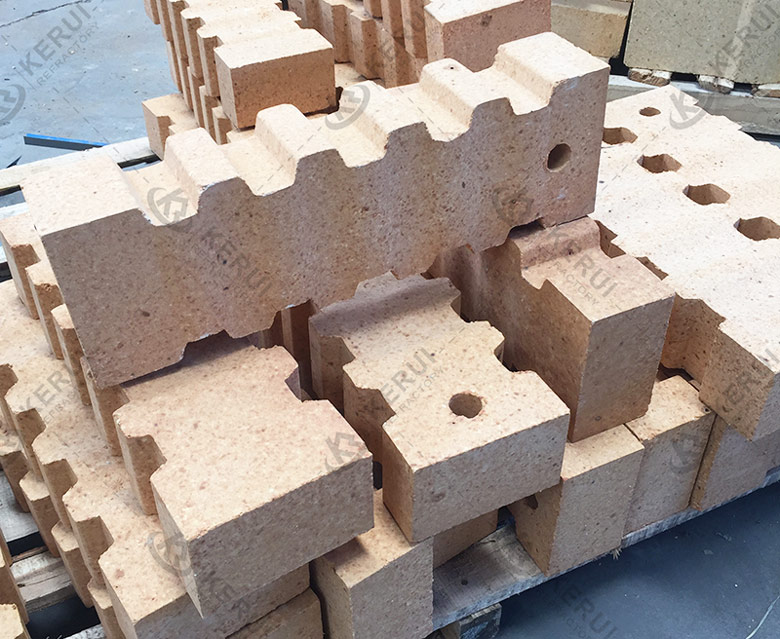

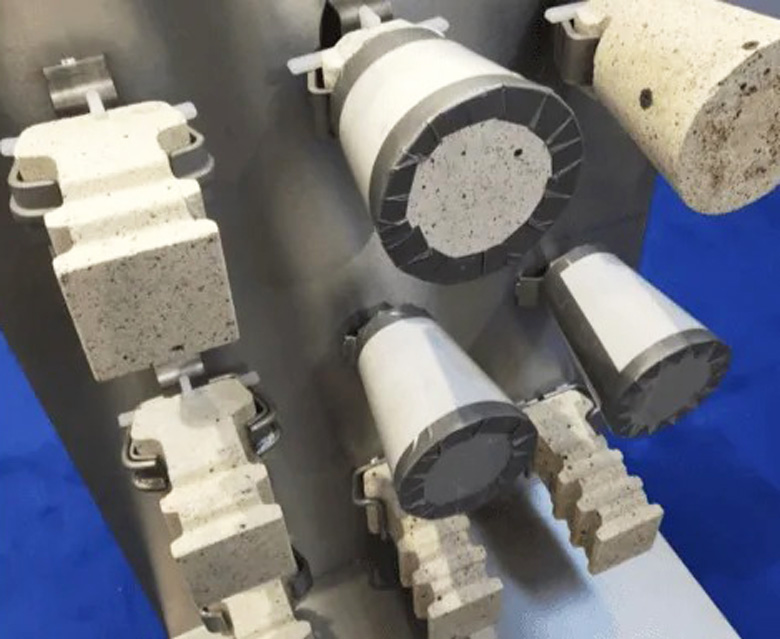

An anchor brick, also called a suspended refractory brick. It is shaped like a cylinder. It has circular grooves and a hole for a pin. The provided parameters highlight the key specifications of our clay and high-alumina anchor bricks. If your project has unique needs, please feel free to contact us.

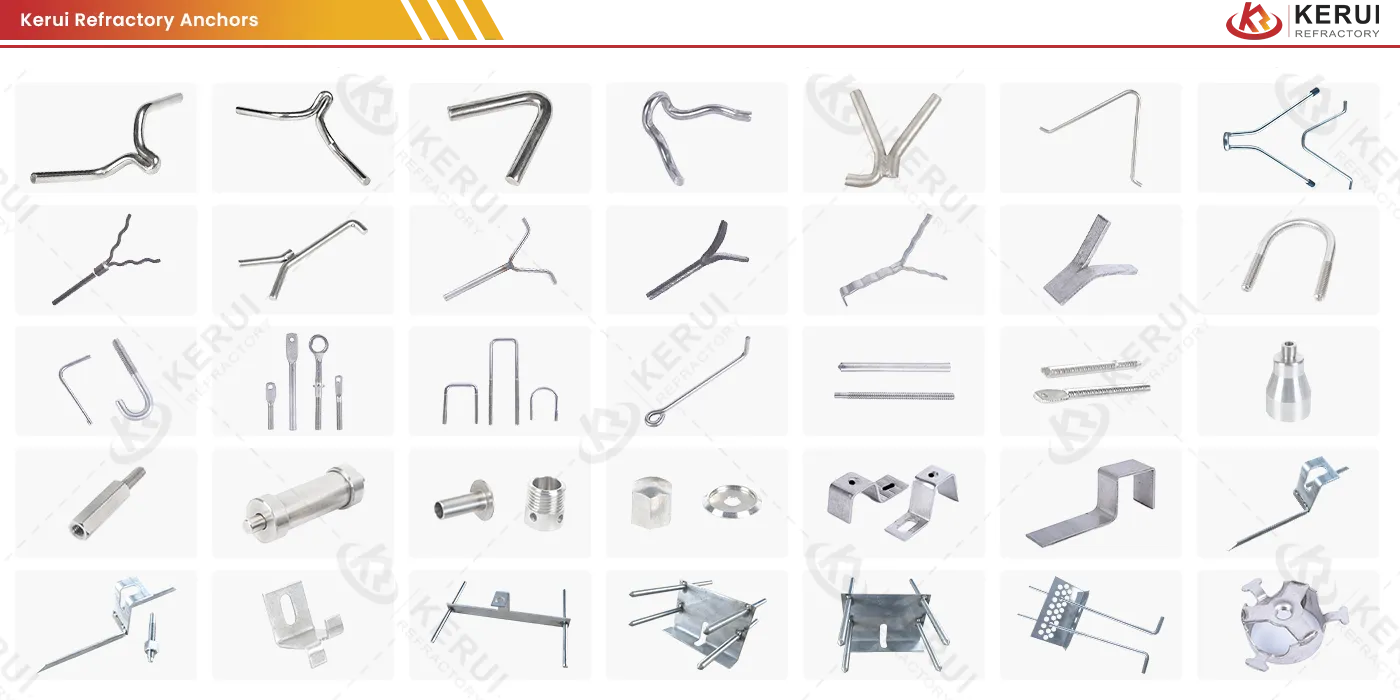

In addition, we can provide matching anchoring devices, like refractory anchors.

| Item/Grade | Fireclay Anchor Brick | High Alumina Anchor Brick | ||||||

|---|---|---|---|---|---|---|---|---|

| FB42-L | AL55 | AL60 | AL65 | AL75 | AL80 | AL85 | CBP80 | |

| Al2O3 % | ≥42 | ≥55 | ≥60 | ≥65 | ≥75 | ≥80 | ≥85 | ≥80 |

| Fe2O3 % | ≤2 | ≤2.0 | ≤2.0 | ≤1.5 | ≤1.5 | / | / | / |

| Refractoriness/℃ | ≥1730 | ≥1790 | ≥1790 | ≥1790 | ≥1790 | ≥1810 | ≥1810 | ≥1810 |

| Permanent Linear Change/% | 1350 ℃×2h | 1500 ℃×2h | 1500 ℃×2h | 1500 ℃×2h | 1500 ℃×2h | 1550 ℃×2h | 1550 ℃×2h | 1550 ℃×3h |

| ±0.2 | ±0.5 | ±0.5 | ±0.5 | ±0.5 | ±0.5 | ±0.5 | ±0.5 | |

| Apparent Porosity/% | ≤23 | ≤24 | ≤23 | ≤23 | ≤23 | ≤22 | ≤20 | ≤18 |

| Bulk Density (g/cm³) | ≥2.15 | ≥2.25 | ≥2.35 | ≥2.40 | ≥2.65 | ≥2.7 | ≥2.75 | ≥2.8 |

| 0.2MPa Refractoriness Underload/℃ | ≥1450 | ≥1450 | ≥1470 | ≥1480 | ≥1500 | ≥1500 | ≥1520 | ≥1450 |

Types of Kerui Anchor Refractory Bricks

| Comparison | Fireclay Anchor Brick | High Alumina Anchor Brick |

|---|---|---|

| Al₂O₃ Content | Lower (Typically 30% – 48%) | Higher (Typically 48% – 80%) |

| Refractoriness | 1250-1420°C | 1420-1530°C |

| High-Temp Strength | ⭐⭐⭐⭐ | ⭐⭐⭐⭐⭐ |

| Thermal Shock Resistance | ⭐⭐⭐⭐⭐ | ⭐⭐⭐⭐ |

| Chemical Resistance | ⭐⭐⭐ | ⭐⭐⭐⭐⭐ |

| Price | Economical | Relatively High |

| Main Applications | Low-temperature zones of kilns (e.g., preheating sections, flues) |

High-temperature key areas of kilns (e.g., furnace roofs, walls, high-temperature zones), heating furnaces, heat treatment furnaces, electric arc furnaces, ladle preheaters, etc. |

Advantages of Kerui Anchor Refractory Bricks

- Precise Dimensions: Kerui produces anchor bricks to exact customer specifications.

- High Anchoring Strength: These bricks securely hold refractory castables in place within furnace linings, ensuring structural integrity and safety.

- High Temperature Resistance: Manufactured from premium refractory materials, our anchor bricks offer exceptional heat resistance.

- High Strength: Kerui bricks boast high mechanical strength and abrasion resistance.

- Excellent Thermal Shock Resistance: These bricks maintain their performance even under rapid temperature fluctuations.

- Strong Corrosion Resistance: Our anchor bricks can withstand the corrosive effects of acids and alkalis.

Applications of Kerui Anchor Fire Bricks

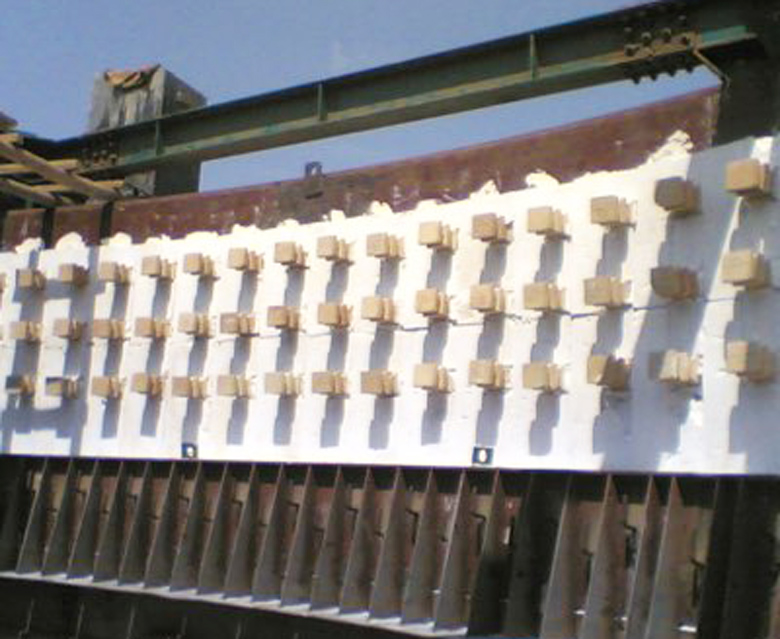

Anchor bricks are primarily used in furnace roofs, linings, and walls.

- Metallurgical Industry: The application of this brick is as furnace linings in equipment such as blast furnaces, converters, torpedo ladles, and electric furnaces.

- Power Industry: Its use is as furnace linings in boilers, heating furnaces, and other related equipment.

- Petrochemical Industry: Its application is as furnace linings in cracking furnaces, gasifiers, reactors, and other process equipment.

- Glass Industry: It is used in furnace linings for glass melting furnaces, sintering furnaces, and so on.

- Ceramics Industry: Used as furnace linings in kilns, heating furnaces, and other related equipment.

Inspection of Anchor Bricks

After completing the production of anchor bricks tailored to customer needs, Kerui conducts comprehensive inspections on dimensions, surface finish, physical and chemical indicators.

Customization of Kerui Anchor Firebricks

Anchor bricks typically come in rectangular or circular shapes. However, recognizing the unique requirements of many customers’ kilns, we offer custom-shaped refractory bricks according to specific drawings and process needs. The tailored design ensures a tight fit between the anchor bricks and the kiln lining, enhancing anchoring effectiveness.

Choose Kerui for Getting Anchor Firebricks

- Source Factory Production: Providing high-quality anchor bricks at factory prices.

- Professional Business Manager: Offering expert advice and solutions.

- Production Quality Control: Highly automated production equipment and a comprehensive quality inspection system.

- Certificates: CE, ISO, and other patent certifications.

- Fast Delivery: Quick dispatch of stock products on time.

- After-Sales Service: Technical guidance and other after-sales support. View more videos on Kerui Youtube.

Related Products