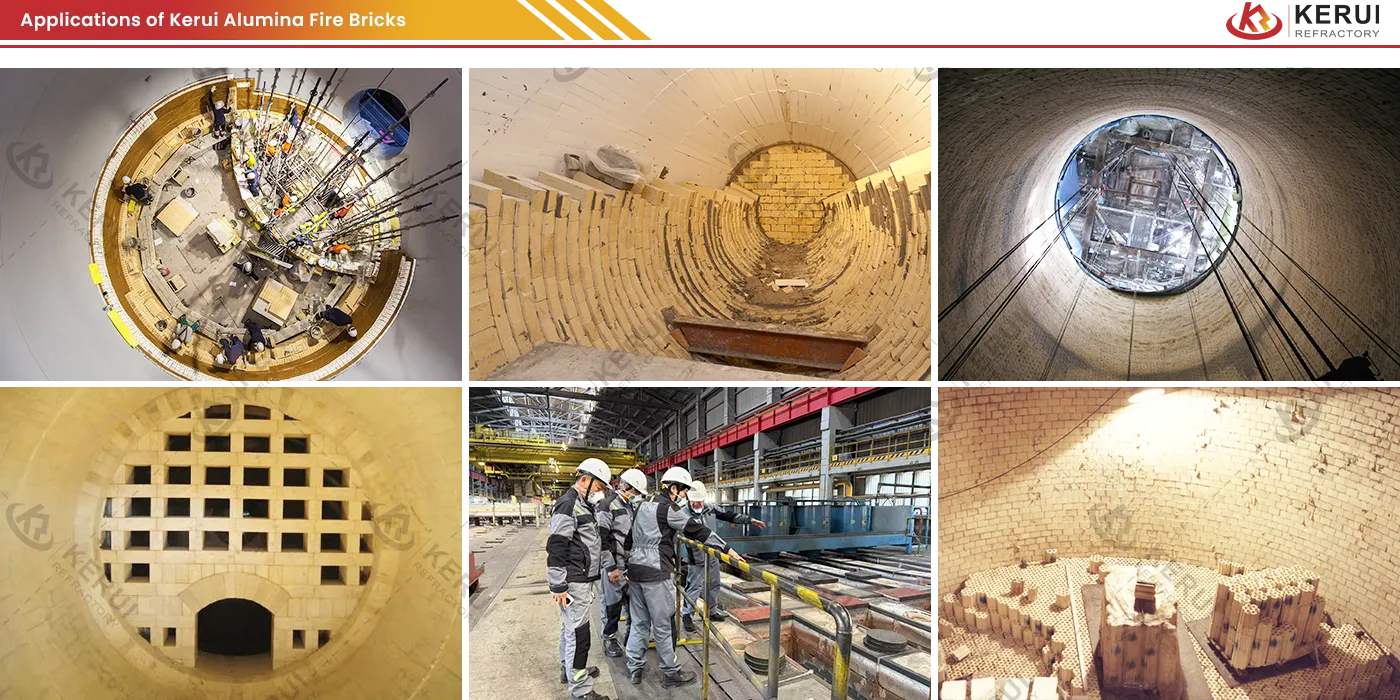

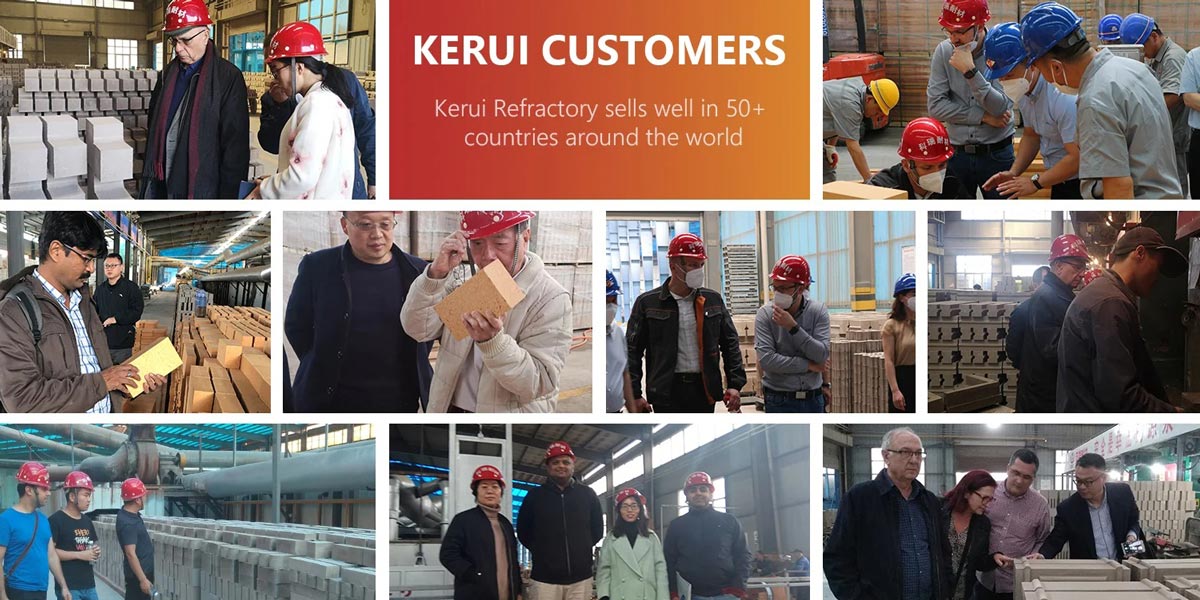

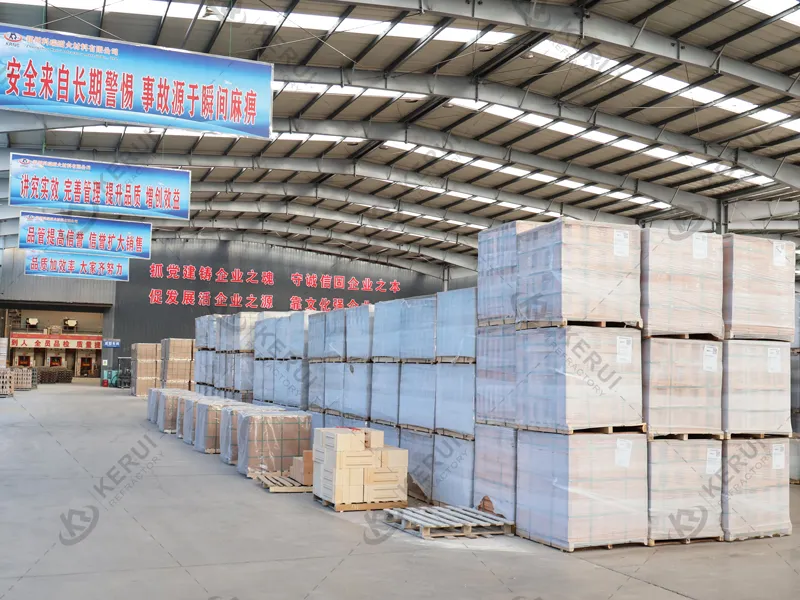

Alumina fire brick is a type of refractory brick with an alumina content of more than 25-99%. This kind of brick has the characteristics of high hardness and high refractoriness. Accordingly, many high-temperature kilns use this kind of fire brick to extend the service life of the kiln. Kerui Refractory offers a large number of in-stock and competitive factory prices.

Kinds of Kerui Alumina Fire Bricks

Based on varying alumina content and mineral composition, Kerui Refractory primarily offers the following types of standard bricks to our partners. In addition to standard refractory brick, we are also committed to catering to our partners’ unique requirements by providing customized brick solutions.

Classified By Mineral Composition

SK Series

Classified By Al2O3

Classified by Property