Alumina bubble brick is a new type of lightweight insulation material mainly composed of corundum. It has the characteristics of low thermal conductivity, high mechanical strength, and strong corrosion resistance. It is suitable for high-temperature corrosive environments. Kerui Refractory provides a large quantity of bricks to 2000+ partners from Russia, Oman, Saudi Arabia, Turkey, Indonesia, Italia, etc.

- Max Service Temperature: 1800℃;

- Al2O3: ≥85-99%;

- Fe2O3: ≤0.2%;

- Bulk Density: 1.4-1.7g/cm³;

- Thermal Conductivity: 0.9-1.2W/(m·K);

- Cold Crushing Strength: 6-18MPa;

- Size: 230*114*65mm (standard)/And other sizes;

- Delivery: 15-30 Working Days;

Specifications of Kerui Bubble Alumina Brick

Kerui Refractory offers three types of alumina bubble bricks. The main differences between these types lie in the alumina content and bulk density. Choose the appropriate insulating bricks based on their physical and chemical properties.

| Item/Grade | 85 | 90 | 99 |

|---|---|---|---|

| Max Service Temperature, ℃ | 1680 | 1700 | 1800 |

| Al2O3, % | ≥85 | ≥90 | ≥99 |

| SiO2, % | ≤13 | ≤8 | ≤0.2 |

| Fe2O3, % | ≤0.2 | ||

| Bulk Density, g/cm³ | 1.4-1.7 | ||

| Cold Crushing Strength, MPa | ≥12 | ≥10 | ≥9 |

| Reheating Linear Change, % (1600℃*3h) | ±0.3 | ||

| Thermal Expansion Coefficient (Room temp-1300℃) | ~7.8 | ~8.0 | ~8.6 |

| Thermal Conductivity Coefficient (1800℃), W/(m·K) | ≤0.8 | ≤1.3 | ≤1.5 |

Introduction of Kerui Bubble Alumina Brick

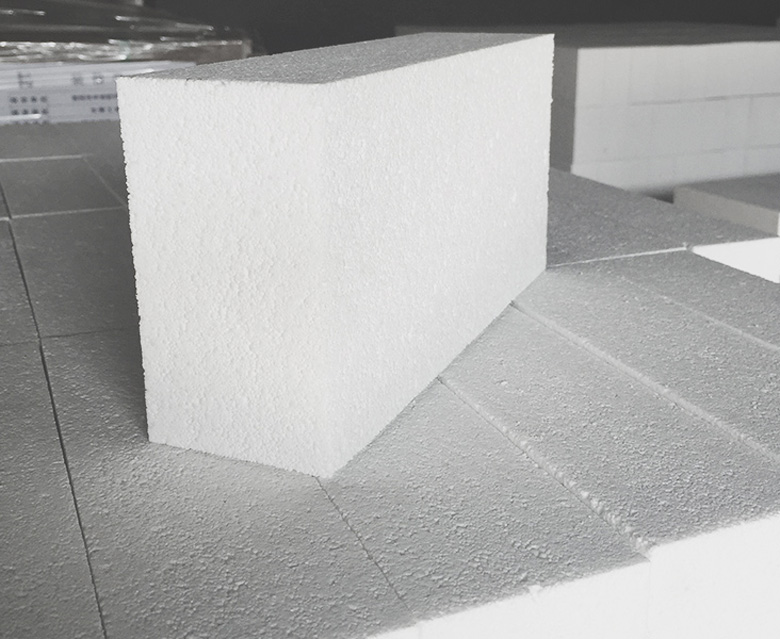

Alumina bubble brick is composed of alumina bubbles. Alumina bubbles are made from high-purity alumina powder. The alumina powder is melted in an electric furnace. And after high-pressure air and low-temperature shrinkage solidification, alumina bubbles are formed. Alumina bubble bricks are mainly composed of a-Al2O3 microcrystals. The maximum operating temperature can reach 1800 degrees Celsius. Kerui Refractory provides alumina bubble bricks with lightweight and good insulation performance.

Advantages of Kerui Bubble Alumina Refractory

High Insulation Ability

The bubble spheres inside the alumina bubble bricks act as insulators. They can greatly reduce heat transfer. Due to their excellent insulation performance, they can help reduce energy loss and improve energy efficiency. Therefore, this feature helps to save costs for businesses.

Enhanced Chemical Stability

The alumina purity in alumina bubble bricks is over 99%. It exhibits stable chemical properties at high temperatures and remains structurally intact in acidic and alkaline environments. This helps extend the lifespan of the equipment.

Strong Thermal Shock Resistance

Alumina bubble bricks have good resistance to thermal shock. In high-temperature environments, they can withstand rapid temperature changes without cracking or spalling. They can be used in extremely high-temperature industries such as steel and glass.

Low Thermal Conductivity

The low thermal conductivity of alumina bubble bricks is related to their insulation properties. The thermal conductivity ranges from 0.9-1.2W/(m·K). It is higher than mullite insulation fire brick‘s. Their low thermal conductivity reduces heat transfer losses. This effectively decreases heat loss in industrial processes and achieves energy savings of over 30%.

Lightweight

They have a high porosity and low volume density. The volume of alumina bubbles ranges from 1.3-1.9g/cm3. The porous bubble structure results in a very light weight. They are easy to handle and transport. This feature helps effectively reduce labor and logistics costs. Additionally, lightweight materials help reduce the weight of buildings.

Environmentally Friendly

These bricks offer environmental benefits. Firstly, their insulation properties help reduce energy consumption for businesses. Secondly, the long lifespan of alumina bubble bricks reduces raw material consumption. Lastly, at the same temperature, the consumption of alumina bubble bricks is lower compared to cost-equivalent refractory bricks. This helps introduce 80% of refractory materials.

Uses of Bubble Alumina Brick

Due to the excellent physical and chemical properties of alumina bubble bricks, they have become one of the choices for high-temperature harsh environments. They not only withstand high temperatures but also provide good energy-saving effects. In order to maintain equipment stability and extend lifespan, they are widely used in the following high-temperature industrial equipment:

- Steel and metallurgical industry: Ladles, tundishes, blast furnaces, steelmaking furnaces, refractory furnaces, molten iron transport equipment, preheating walls, flat storage chambers, coke ovens, reheating furnaces, induction kilns, molybdenum furnaces, tungsten rod furnaces, electric furnaces, and so on.

- Petrochemical industry: Gasifiers, gasifiers, carbon black reaction furnaces, cracking units, reactors, catalyst carriers, and so on.

- Ceramic industry: Ceramic kilns, ceramic storage chambers, and so on.

- Cement industry: Cement kilns, and so on.

- Glass industry: Glass kilns, glass storage chambers, and so on.

Kerui Refractory is the Top-leading Manufacturer

Among global alumina bubble brick manufacturers, Kerui Refractory has unparalleled advantages and strength. Many customers in high-temperature industries choose our products and services.

Brand Strength

- Rank top three in the refractory industry in China;

- High brand recognition among customers;

- Over 20 patents, ISO and other international certifications.

Factory

- 20-years experience in production, quality inspection, and shipping;

- Located in the refractory production base in Xinmi City, Henan Province, China;

- Strictly digitalized production and testing systems.

Services

- Alumina bubble brick matching refractory solution design;

- Fast delivery with synchronized shipping logistics information;

- On-site construction guidance, and technical support.

Contact Kerui Refractory to Get Alumina Hollow Bricks

Kerui Refractory offers high-quality alumina hollow bricks. We have advanced production technology and comprehensive services to help customers obtain premium products and services. Whether it’s special products, matching solution design, or on-site construction guidance, we can meet your needs. Choose the trustworthy Kerui Refractory as your partner. View Kerui Facebook to follow us.