In August 2025, Kerui successfully completed the export of 2 containers of ceramic fiber insulation board to a Hungarian customer. These products will primarily be used as insulation linings for local industrial kilns in Hungary. It helps the customer improve the energy efficiency and operational stability of their high-temperature equipment.

Parameters and Advantages of Ceramic Fiber Board Shipped to Hungary in August 2025

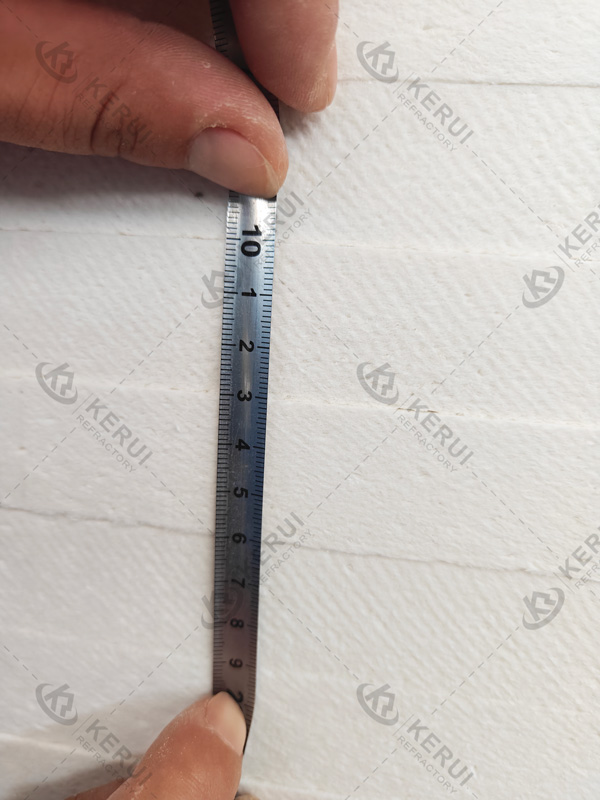

The main technical specifications of the ceramic board delivered are as follows:

- Classification Temperature: 1260°C.

- Bulk Density: 300 kg/m³ (lightweight, high-strength structure).

- Specifications: Standard dimensions: 600×400×25/50mm (customization available).

- Compliant Standards: GB/T 3003-2017, ISO, etc.

- Excellent high-temperature resistance: It can operate stably at 1260°C for long periods of time and withstand short-term temperatures up to 1400°C.

- Low thermal conductivity effectively reduces kiln heat loss, achieving energy savings of 15%-20%.

- Excellent mechanical strength: Flexural strength ≥ 0.8 MPa. It meets the airflow scouring requirements of industrial kilns.

- Environmentally friendly and safe: Asbestos-free. And it is compliant with EU REACH regulations.

The Customer Chose Kerui’s Ceramic Fiber Board

This collaboration stemmed from a kiln renovation project for a medium-sized steel processing company in Hungary. The company’s existing insulation material was more than six month old. It significantly reduces thermal efficiency. After multiple rounds of technical comparisons, Kerui’s ceramic fiber board was ultimately selected to replace traditional refractory bricks. The key factors were:

- 40% weight reduction: The 300 kg/m³ bulk density significantly reduces the load on the kiln’s steel structure.

- Easy installation: The boards can be cut on-site. And it shortens the installation cycle by 50% compared to masonry refractory fire bricks.

- Low maintenance costs: The expected service life is 30% longer than traditional materials.

Technical Consultation from Kerui Refractory

Have you encountered the following issues during your kiln energy-saving retrofit? Kerui will offers a satisfied solution to you after you sending the details.

- The marketing effectiveness of the existing insulation material;

- Severe heat loss leading to increased energy costs;

- Frequent maintenance affecting production continuity;

Please leave a message describing your specific operating conditions, and our engineers will recommend the optimal insulation solution.