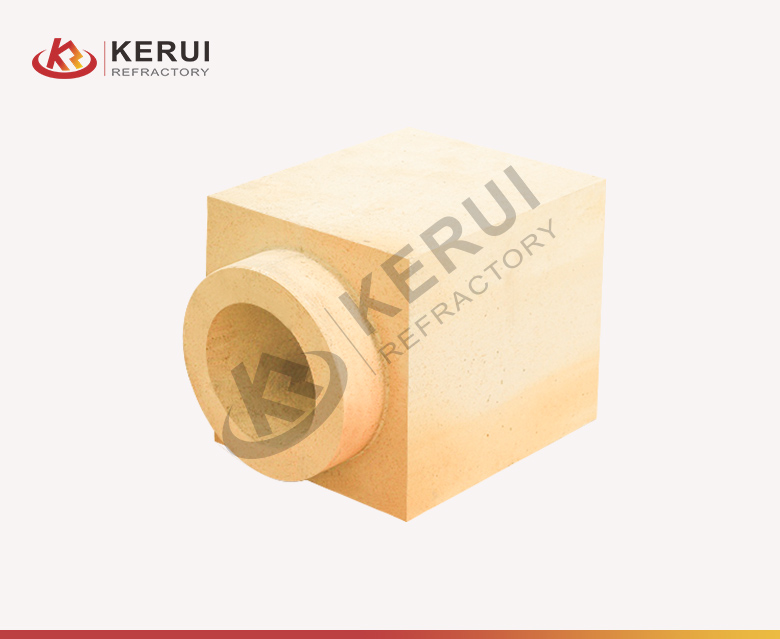

Refractory well block plays a crucial role in the continuous casting process of the steel industry. Kerui, as a manufacturer and supplier, offers both standard and customized sizes. Additionally, Kerui can provide technical guidance according to customers’ specific needs.

- Materials: 5+ Materials;

- Size: Common & Customized Size;

- Certificates: ISO14001, ISO9001, CE, Etc.;

- Test: Support Third-party Testing;

- Shipment: 15-30 Working Days;

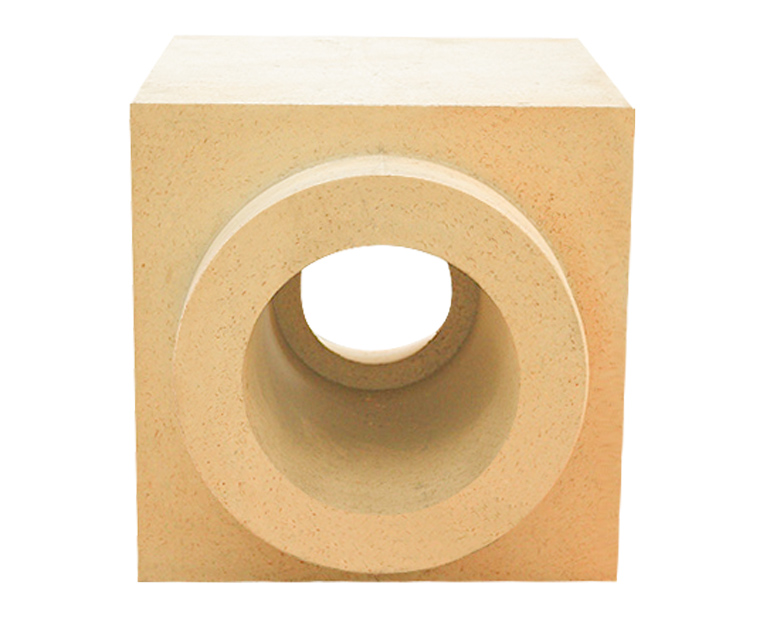

Types of Refractory Well Block

This refractory brick consists primarily of tundish well blocks and ladle well blocks. Select the suitable type based on their specific characteristics.

| Difference | Tundish Well Block | Ladle Well Block |

| Location | Bottom of the tundish | Bottom of the ladle |

| Primary Function | Controls the flow rate of molten steel into the mold and improves steel cleanliness | Controls the flow rate of molten steel from the furnace into the ladle and, in some cases, adjusts the steel composition |

| Operating Stage | Continuous casting process | Steelmaking and teeming process |

Material Composition of Refractory Well Blocks

Kerui refractory well blocks are available in a range of materials, such as alumina, magnesia, carbon, silica, and zirconia. The choice of material is determined by factors including operating conditions, installation site, and process demands. Our experienced engineers can provide tailored material recommendations based on your specific application.

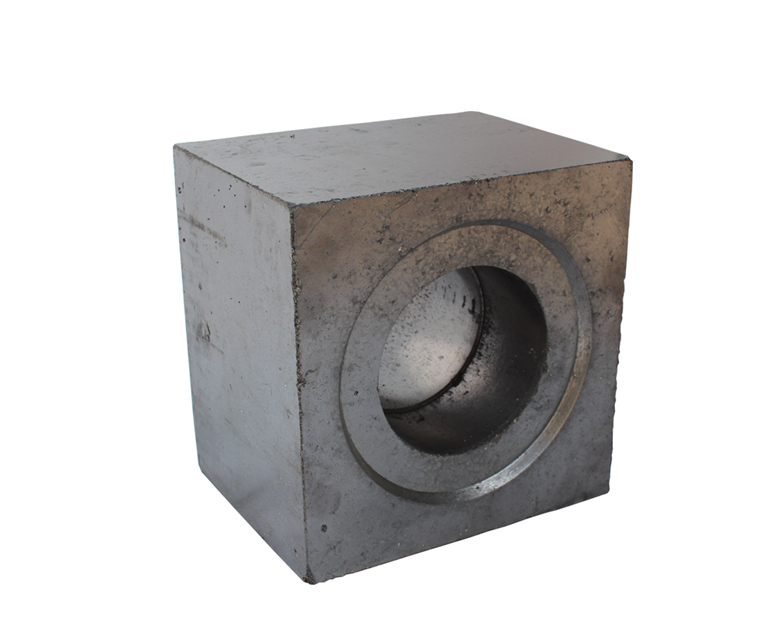

Production of Kerui Refractory Well Block

- Possess large-scale production capacity and a complete production system in Kerui factory.

- Use high-quality raw materials that meet industry standards.

- Formed through high-temperature sintering.

- Digital control of production processes.

- Standardized product testing.

- Surface and dimensional tolerance measurement.

Features of Kerui Refractory Well Block

- High temperature resistance;

- Corrosion resistance;

- Thermal shock resistance;

- High strength;

- Good thermal conductivity or insulation;

- Dimensional stability;

- Various materials;

- Various shapes;

- Complete specifications;

- Long service life.

Packaging of Kerui Refractory Well Block

Kerui provides standard fumigated wooden pallet packaging. In addition, Kerui also offers customized packaging to meet customer requirements.

Shipping of Refractory Well Block

So far, Kerui bricks have been shipped to over 30 customers. See some cases here.

- Typically, for standard products, Kerui will ship within 15-30 working days.

- For customized products, Kerui will ship within approximately 35 working days. Our sales manager will confirm the specific details with you.

Application of Well Block Refractory

The ladle aeration brick is an indispensable key component in secondary metallurgy. By accelerating metallurgical reactions, homogenizing molten steel, and removing inclusions, it significantly improves steel quality and ensures the smooth progress of the refining process.

The ladle well bricks needs to be regularly replaced and maintained to ensure smooth molten steel flow and the sealing of the ladle.

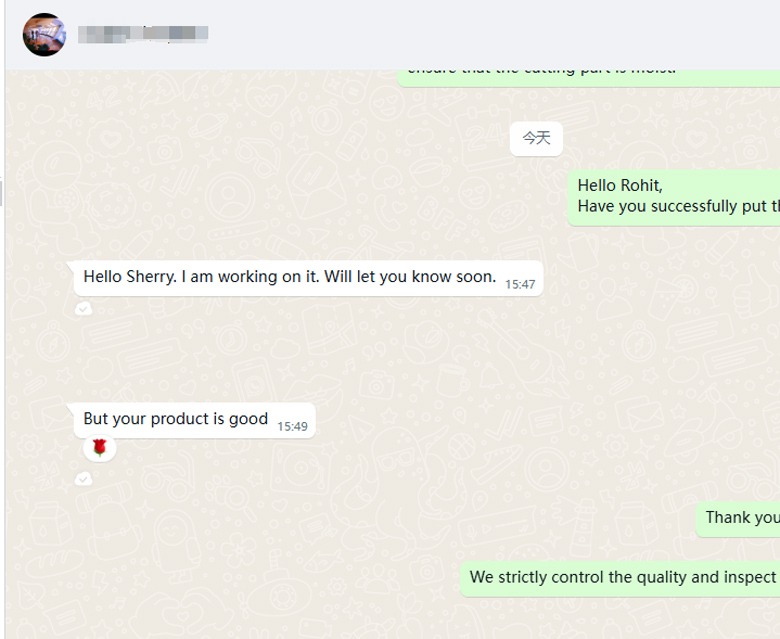

Customer Satisfaction with Kerui Well Block

70% of customers choose to repurchase our products.

- Fast response time and high communication efficiency.

- Professional technical guidance.

- Comprehensive and supporting refractory products.

- High product quality.

Kerui is Your Top Refractory Well Block Manufacturer

- Source manufacturing factory;

- Offers a wide range of products;

- Professional technical support;

- Comprehensive after-sales service.

Contact Kerui for Cooperation

Kerui offers a comprehensive range of high-quality refractory well blocks tailored to the specific needs of the steel industry. With a focus on innovation, quality, and customer satisfaction, Kerui provides reliable and efficient solutions to optimize your steelmaking processes. Choose Kerui and improve your steelmaking operations to new heights. View some news in Linkedin.