Kerui bio soluble ceramic fiber products ensure operational safety and enhance energy efficiency in modern industry. Delivering superior thermal insulation, their revolutionary biosoluble nature eliminates health risks associated with traditional refractory fibers, setting a new safety benchmark for your workplace. We are committed to providing a safer, more efficient, and responsible comprehensive insulation solution—from energy conservation to occupational health.

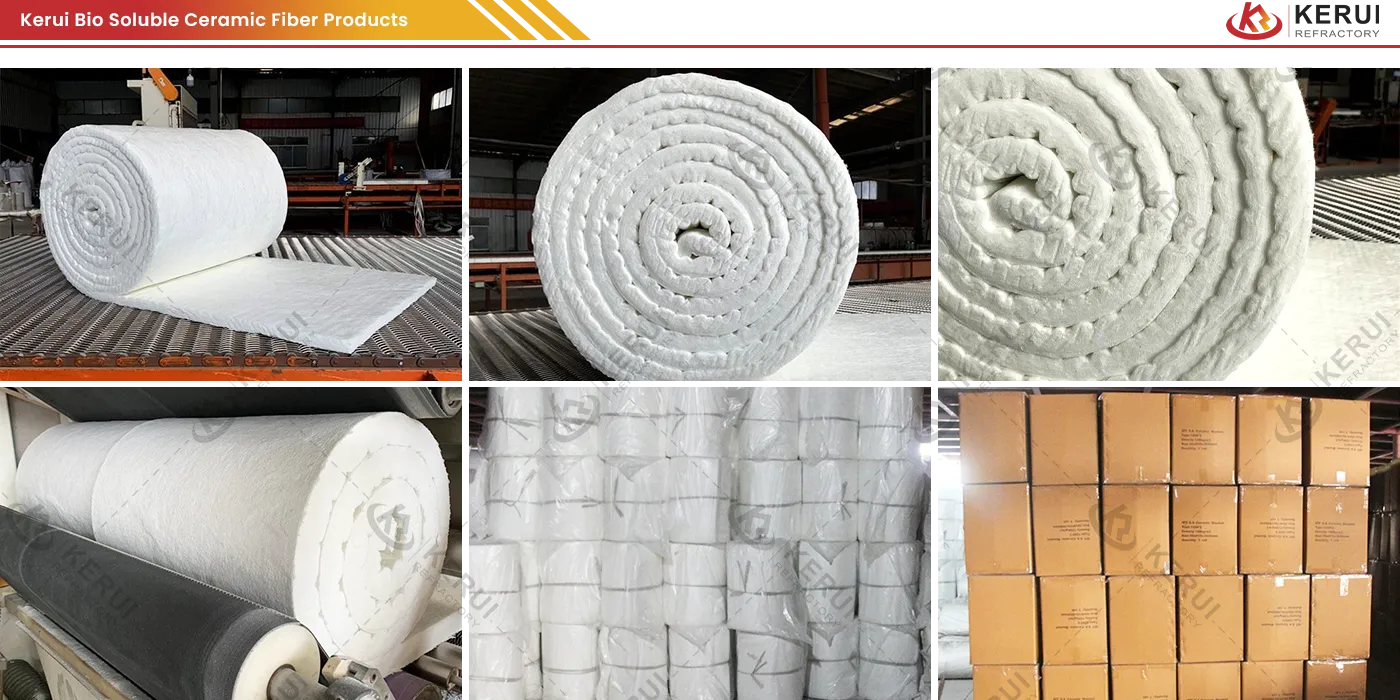

Kerui Bio Soluble Ceramic Fiber Products for Sale

Bulk Density: 64-500g/cm³;

Classification Temp: 1100-1300ºC;

Thickness: 6-60mm;

Bulk Density: 250-300g/cm³;

Classification Temp: 1100-1300ºC;

Thickness: 3-100mm;

Bulk Density: 172-220g/cm³;

Classification Temperature: 1100-1300ºC;

Accessories: Anchors;

Bulk Density: 180-200g/cm³;

Classification Temperature: 1100-1300ºC;

Thickness: ≥1mm;

Bulk Density: 380-500g/cm³;

Classification Temperature: 1100-1300ºC;

Size: Φ6-50mm;

Bulk Density: ≥500kg/m³;

Classification Temperature: 1100-1300ºC;

Thickness: ≥3mm;

| Product Type | Key Characteristics |

|---|---|

| Biosoluble Fiber Blanket | Basic insulating material, flexible, easy to cut and wrap |

| Biosoluble Fiber Board | Certain structural strength, load-bearing, easy to machine |

| Biosoluble Fiber Module | Pre-formed, rapid installation, stable and uniform lining structure |

| Biosoluble Fiber Paper | Thin, soft texture, used for precise separation and sealing |

| Biosoluble Fiber Rope | Flexible, used for filling irregular gaps and dynamic sealing |

| Biosoluble Fiber Shapes | Custom-made to drawings for special shapes and non-standard structures |

Parameters of Kerui Soluble Fiber Products

| Product Code | KR-AES-21 (Cotton) | KR-AES-21F (Cotton) | KR-AES-22 (Blanket) | KR-AES-54 (Paper) | KR-AES-43 (Board) | KR-AES-35 (Module) | KR-AES-67 (Rope) | |

|---|---|---|---|---|---|---|---|---|

| Classification Temperature (°C) | 1100 | |||||||

| Bulk Density (kg/m³) | - | - | 64-160 | 180-200 | 250-350 | 180-240 | 500 | |

| Thermal Conductivity Average 500°C (W/(m·K)) | ≤0.153 | ≤0.153 | ≤0.153 | ≤0.153 | ≤0.153 | ≤0.153 | ≤0.153 | |

| Linear Shrinkage (%) | - | - | 1000°C×24h≤4 | 1000°C×24h≤4 | 1000°C×24h≤4 | 1000°C×24h≤4 | - | |

| Organic Content (%) | - | - | - | ≤10 | ≤5 | - | ≤15 | |

| Shot Content (Φ≥0.212mm) (%) | ≤20 | ≤20 | ≤20 | - | - | - | ||

| Chemical Composition (%) | CaO | 28-32 | ||||||

| MgO | 3-6 | |||||||

| SiO₂ | 60-66 | |||||||

| Al₂O₃ | ≤1 | |||||||

Soluble Fiber Products Vs. Ceramic Fiber Products Vs. Polycrystalline Insulation Products

In order to meet the needs of various industries and parts of the body, Kerui Refractory provides the following forms of soluble fiber products.

| Property | Soluble Fiber (Biosoluble Fiber) | Ceramic Fiber (Standard Type) | Polycrystalline Mullite Fiber (PMF) |

|---|---|---|---|

| Main Composition | Calcium-Magnesium-Silicate system, contains little or no crystalline silica. | Alumina-Silica, typically containing 45%-55% Alumina. | ≥98% Polycrystalline Mullite Phase, Alumina content ~72%-78%. |

| Max. Service Temperature | ★★★ Classification Temp.: 1100°C |

★★★★ Classification Temp.: 1260°C – 1430°C |

★★★★★ Classification Temp.: 1500°C – 1600°C |

| Health & Safety | ★★★★★ Soluble in body fluids |

★★ Contains crystalline silica |

★★★★ Low bio-persistence |

| Cost | ★★★ Medium |

★★ Lowest |

★★★★★ Very High |

| Key Positioning | “Safer Alternative” | “Cost-Effective Workhorse” | “Performance King for Ultra-High Temperatures” |

Features of Kerui Bio Soluble Insulation

- Biosoluble: Its chemical components do not persist in the lungs, significantly reducing long-term health risks.

- Non-carcinogenic classification: It is classified as non-carcinogenic by major international health and safety agencies, including the EU CLP regulation. This provides enhanced safety for workers during production, processing, and installation.

- Excellent high-temperature resistance: It can withstand long-term use at temperatures up to ~1000°C – 1100°C.

- Excellent thermal insulation: Like ceramic fibers, it has a low thermal conductivity, effectively preventing heat loss and significantly reducing energy consumption.

- Low heat capacity: Its low heat storage capacity allows for rapid heating and cooling of industrial kilns, making it particularly suitable for intermittent kilns with frequent starts and stops, further improving energy efficiency.

- Chemical stability: It is chemically stable in most high-temperature atmospheres, except for dissolving in certain body fluids, and exhibits excellent resistance to acid and alkali corrosion.

Applications of Bio Soluble Fiber

Different forms of soluble fiber products, due to their unique physical form and properties, are suitable for different industrial applications, forming a complete set of high-temperature thermal insulation solutions. This diverse product form ensures safe, efficient, and reliable thermal insulation, from the main insulation to the detailed treatment.

| Product Type | Common Industries | Typical Furnace / Equipment Applications |

|---|---|---|

| Biosoluble Fiber Blanket | Petrochemical, Chemical, Ceramics, Non-ferrous Metals, Heat Treatment | Lining for cracking/reforming furnaces, backup insulation for annealing furnaces, insulation layer for roller hearth kilns, pipe wrapping |

| Biosoluble Fiber Board | Heat Treatment, Glass, General Industry | Lining for furnace doors/walls, lining for pit furnaces, kiln car tops, insulating boards for glass melters |

| Biosoluble Fiber Module | Steel, Petrochemical, Building Materials, Non-ferrous Metals | Roofs and walls of heating/annealing furnaces, hot zone lining for cracking furnaces, lining for cement pre-calciners |

| Biosoluble Fiber Paper | Heat Treatment, Appliance, Laboratories, Metallurgy | Separating sheets for heat-treated workpieces, insulation for domestic ovens, lining for laboratory furnaces |

| Biosoluble Fiber Rope | All Industrial Sectors | Sealing for furnace doors/viewing ports, stuffing for thermocouple ports, sealing packing for valve flanges |

| Biosoluble Fiber Shapes | Metallurgy, Heat Treatment, Ceramics | Burner blocks, furnace plug doors, support pads, conical sleeves, special pipe supports |

From Delivery to Operation: Partnering with You for Safer Insulation

Kerui soluble fiber products are currently supplied to over 15 countries worldwide. Market feedback confirms that they excel in reducing energy consumption, improving installation safety, and complying with stringent environmental regulations, directly improving overall profitability for our customers. Building on these successful international collaborations, we are committed to bringing even higher-quality solutions to even more global partners. View some YouTube videos.